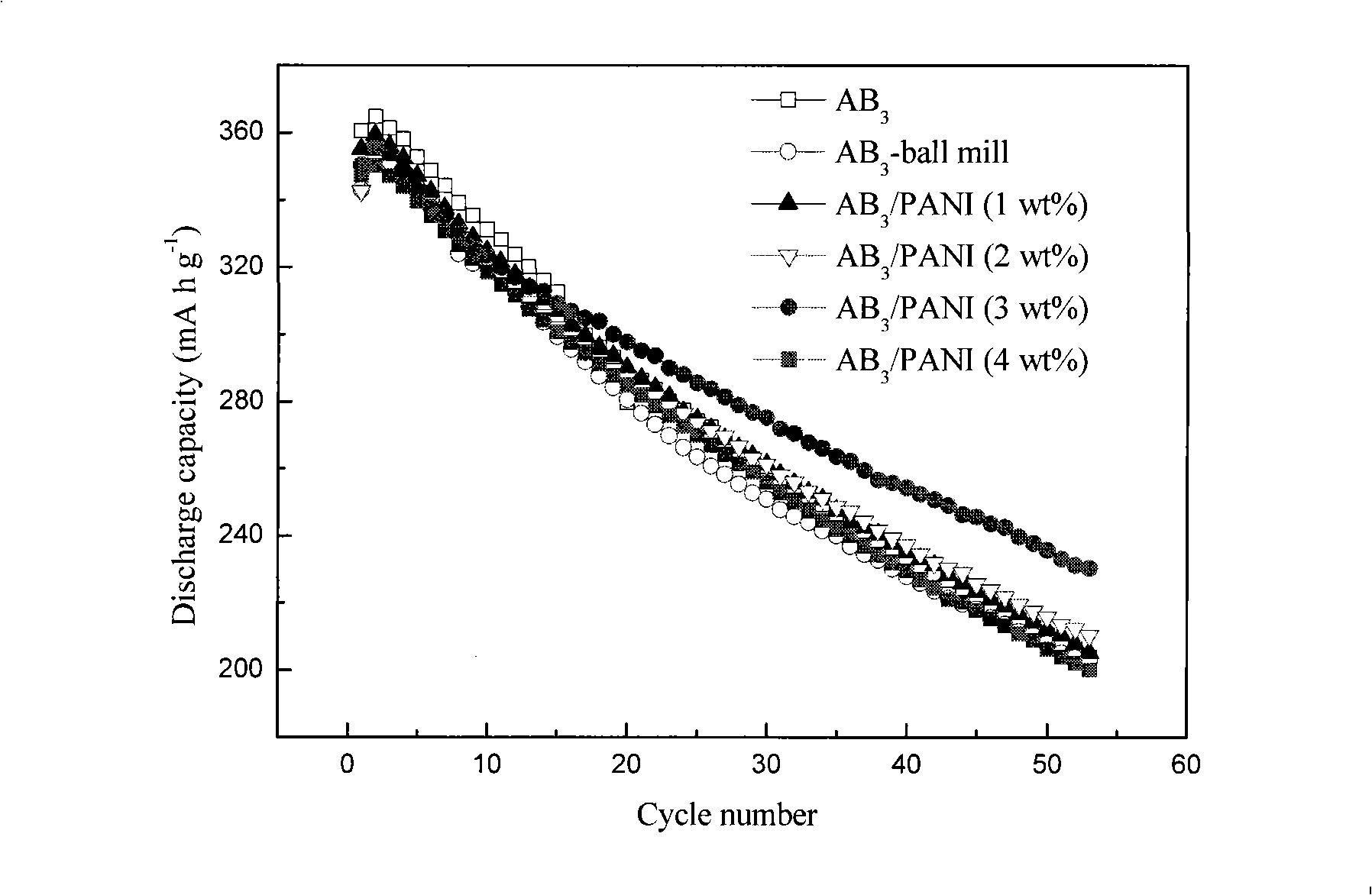

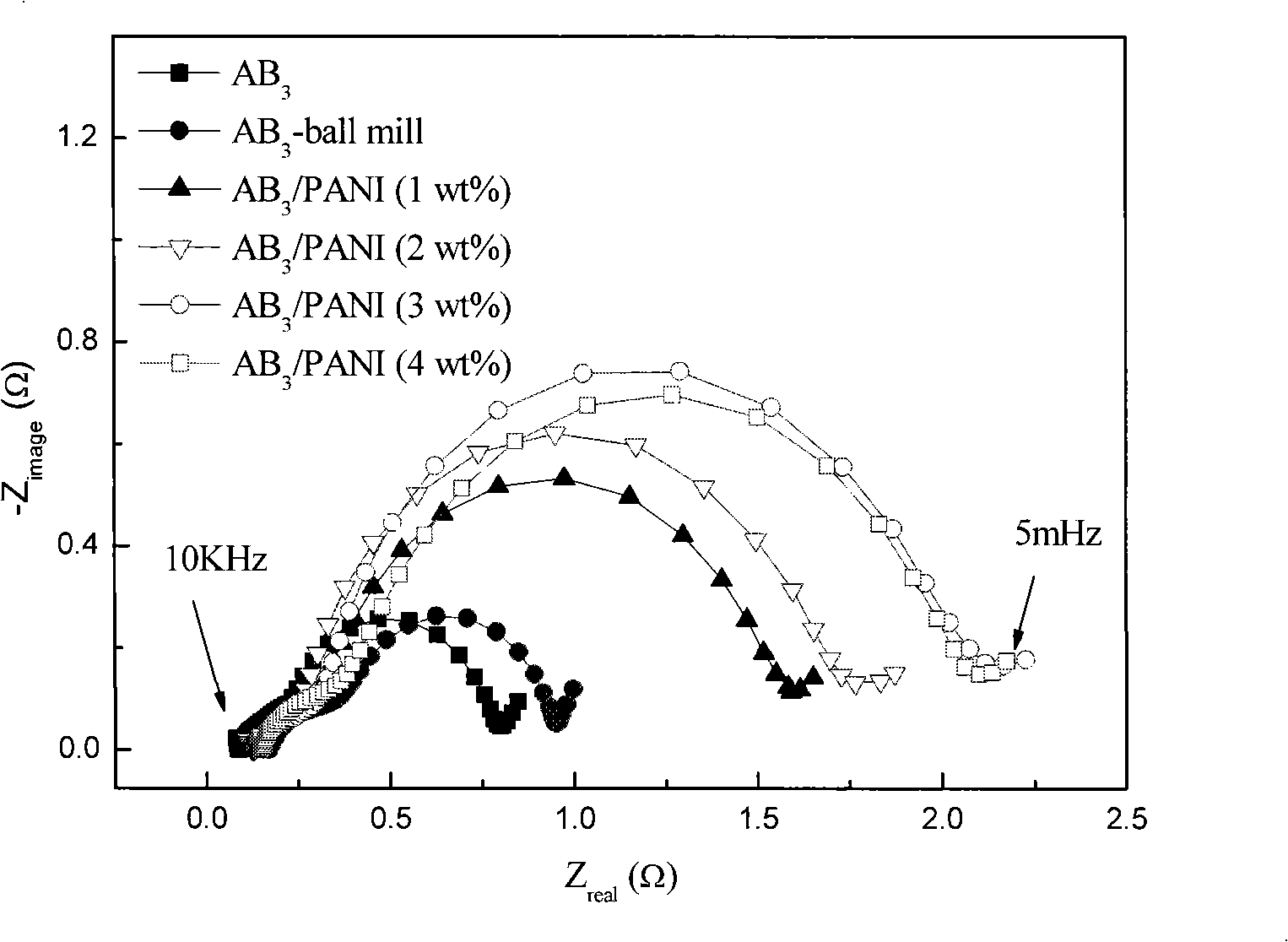

Composite material of conducting high polymers/alloy for nickel-hydrogen battery and preparation thereof

A conductive polymer and composite material technology, applied in the field of alloy composite materials for nickel-hydrogen batteries, can solve problems such as affecting the performance of alloy electrodes, poor cycle stability, alloy powdering, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 0.5ml of double-distilled aniline monomer and dissolve it in 10mL of deionized water, then add 2.6mL of 2mol / L hydrochloric acid, and after stirring for about 30min, add dropwise an aqueous solution of ammonium persulfate (2.56g of ammonium persulfate dissolved in 11mL of water ), the average rate of addition is 20drop / min, after all the dropwise addition, then stir and react for 12h, the product obtained is washed and filtered by methanol and water (polyaniline is washed with methanol to remove unreacted aniline monomer, polyaniline has better conductivity), baked in a vacuum oven at 60°C for 24 hours, and set aside.

[0029] AB 3Alloy according to La 0.7 Mg (0.3-x) Ti x Ni y co 3.5-y (x = 0.02 ~ 0.06, y = 2.9 ~ 3.2), put each metal into a high-temperature melting furnace, protect it with argon, heat up and smelt, repeat 3 times, and obtain evenly smelted AB 3 alloy, the AB 3 The alloy block is crushed, ground, passed through a 300-mesh sieve, and set aside...

Embodiment 2

[0039] The difference from Example 1 is that polypyrrole is prepared by injecting 1 mL of pyrrole monomer that has been distilled 4 times into 100 mL of an acidic aqueous solution of ammonium persulfate (ammonium persulfate is 3.12 g). The reaction was carried out under stirring for 12 hours, and the obtained product was washed and filtered with methanol and water (polypyrrole was washed with methanol to remove unreacted aniline monomer, polyaniline has better electrical conductivity), and baked in a vacuum oven at 60°C for 24 hours ,spare.

[0040] AB 3 Alloy according to La 0.7 Mg (0.3-x) Ti x Ni y co 3.5-y (x=0~0.02, y=3.3~3.5) proportioning, smelting preparation conditions are the same as embodiment 1. Will AB 3 The alloy block is smashed, ground, and passed through a 200-300 mesh sieve, and the intermediate product is taken for later use.

[0041] Take 1g of AB through 200-300 mesh sieve 3 The alloy is mixed with 0.01g of polypyrrole, put into an agate ball mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com