PMMA-coated hollow tin alloy nanoparticles and preparation method and application thereof

A technology of alloy nanoparticles and nanoparticles, which is applied in the field of nanomaterials and its applications, can solve the problems of poor structural stability and interface stability, and achieve the effects of mild and controllable conditions, good electrochemical performance, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the PMMA-coated hollow tin alloy nanoparticles may further comprise the steps:

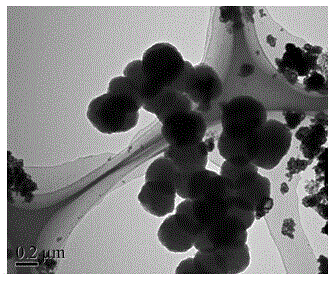

[0034] 1) Weigh 2g NiCl 2 ·6H 2 O was stirred and dissolved in 100 mL of absolute ethanol, and 1 mol / L NaOH solution was added dropwise under stirring conditions to adjust the pH value to 12, heated to 60 °C, and 15 mL of hydrazine hydrate ( 80wt%), constant temperature and continuous stirring reaction for 50 min; after the reaction, the black substance was centrifuged at a speed of 10000 r / min, washed 3-5 times with distilled water and absolute ethanol respectively, and then the black substance was placed in In a vacuum drying oven, vacuum-dry at 80 °C for 12 h to prepare nickel nanoparticles, which are stored for later use; the prepared nickel nanoparticles are analyzed by transmission electron microscope, and the results are as follows: figure 1 shown.

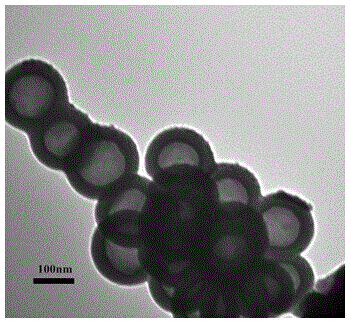

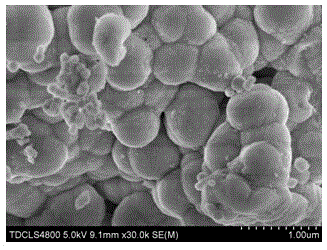

[0035] 2) Weigh 1.5 g SnSO 4 Dissolved in 150 mL of distilled water, stirred magnetically, and then weigh...

Embodiment 2

[0038] The preparation method of the PMMA-coated hollow tin alloy nanoparticles may further comprise the steps:

[0039] 1) Weigh 2g NiCl 2 ·6H 2 O was stirred and dissolved in 100 mL of absolute ethanol, and 1 mol / L NaOH solution was added dropwise under stirring to adjust the pH value to 12, heated to 70°C, and 15 mL of hydrazine hydrate ( 80wt%), constant temperature and continuous stirring reaction for 50 min; after the reaction, the black substance was centrifuged at a speed of 10000 r / min, washed 3-5 times with distilled water and absolute ethanol respectively, and then the black substance was placed in In a vacuum drying oven, vacuum-dry at 80 °C for 12 h to prepare nickel nanoparticles, which are stored for later use.

[0040] 2) Weigh 1.5 g SnSO 4 Dissolved in 150 mL of distilled water, stirred magnetically, and then weighed 0.5 g of Ni nanoparticles, ultrasonically dispersed in the above-prepared SnSO 4 solution; the oil bath was heated to 100 °C, and the reactio...

Embodiment 3

[0044] The preparation method of the PMMA-coated hollow tin alloy nanoparticles may further comprise the steps:

[0045] 1) Weigh 2g NiCl 2 ·6H 2 O was stirred and dissolved in 100 mL of absolute ethanol, and 1 mol / L NaOH solution was added dropwise under stirring to adjust the pH value to 12, heated to 80°C, and 15 mL of hydrazine hydrate ( 80wt%), constant temperature and continuous stirring reaction for 50 min; after the reaction, the black substance was centrifuged at a speed of 10000 r / min, washed 3-5 times with distilled water and absolute ethanol respectively, and then the black substance was placed in In a vacuum drying oven, vacuum-dry at 80 °C for 12 h to prepare nickel nanoparticles, which are stored for later use.

[0046] 2) Weigh 1.5 g SnSO 4 Dissolved in 150 mL of distilled water, stirred magnetically, and then weighed 0.5 g of Ni nanoparticles, ultrasonically dispersed in the above-prepared SnSO 4 solution; the oil bath was heated to 120 °C, and the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com