Iron lithium manganese phosphate series particles, and iron lithium manganese phosphate series powder and preparation method therefor

A lithium ferromanganese phosphate-based and second lithium-manganese ferrophosphate-based technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve low electrical conductivity, poor charge-discharge cycle stability and thermal stability , low electrical conductivity of lithium manganese iron phosphate powder, etc., to achieve high energy density, good charge-discharge cycle stability, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]

[0047] The preparation method of the lithium manganese ferrophosphate powder comprises the following steps: grinding and granulating the admixture containing the lithium source, manganese source, iron source and phosphorus source to form the granulation mixture; The granulated mixture is sequentially subjected to preliminary sintering treatment, intermediate sintering treatment and final sintering treatment.

[0048] Preferably, the phosphorus source is water soluble. The types of phosphorus sources are, for example but not limited to, phosphoric acid, ammonium dihydrogen phosphate, sodium phosphate or sodium dihydrogen phosphate, etc., and the above phosphorus sources can be used alone or in combination. More preferably, the phosphorus source is phosphoric acid.

[0049] The types of manganese sources are, for example but not limited to, manganese oxide, manganese oxalate, manganese carbonate, manganese sulfate or manganese acetate, etc., and the above manganese s...

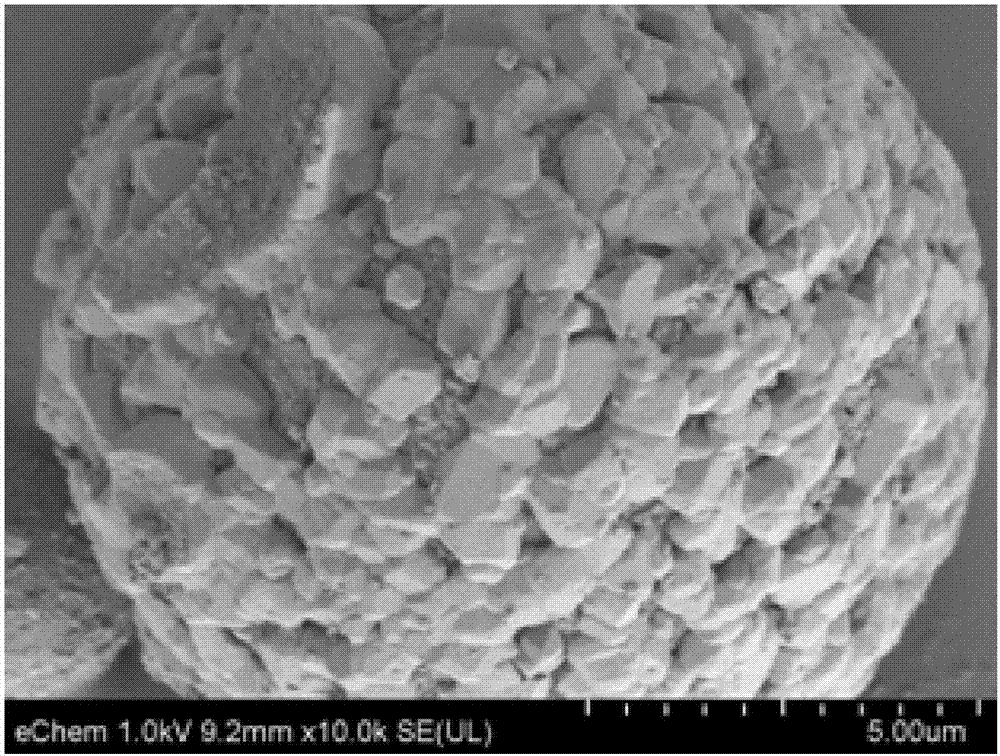

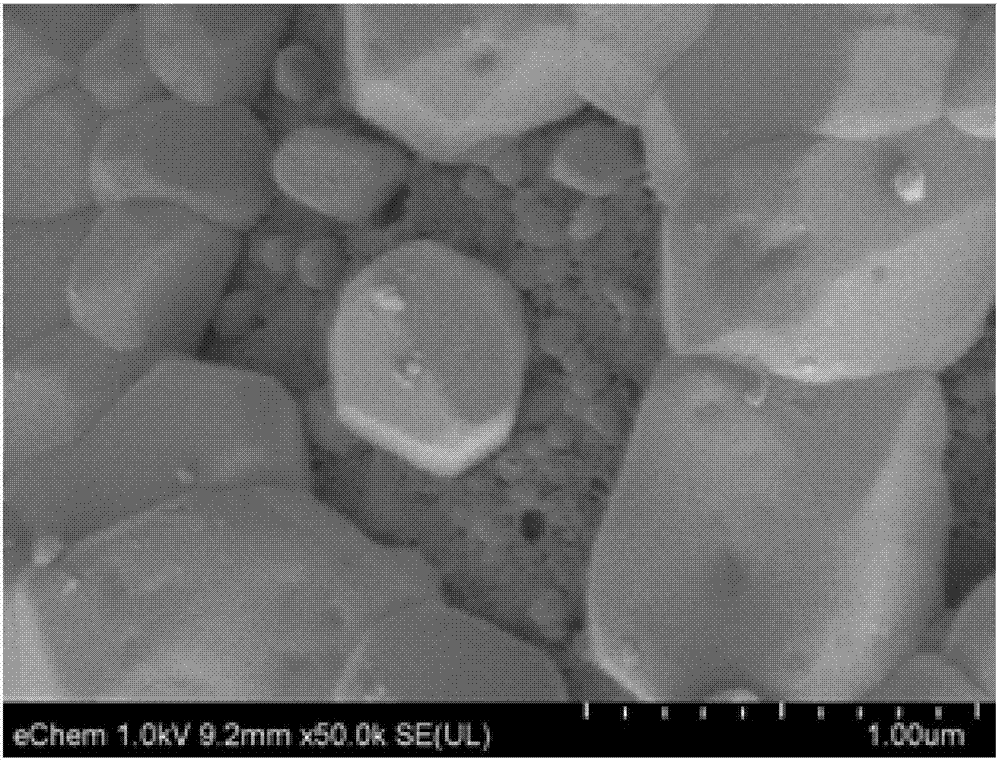

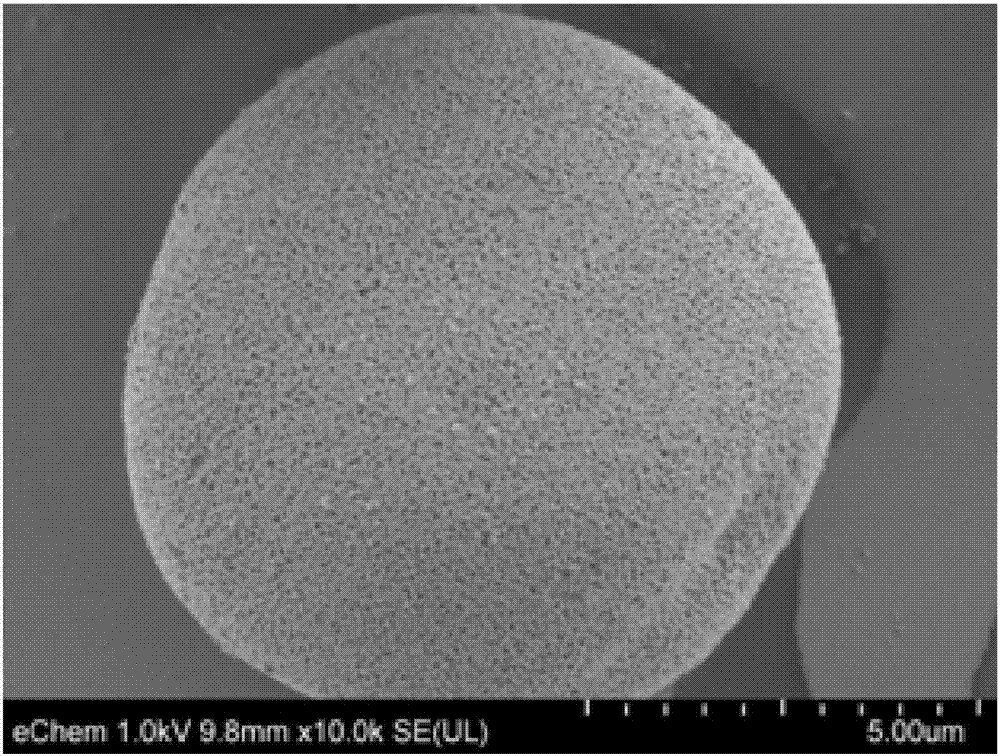

Embodiment 1

[0061] Under the condition that the temperature is greater than 30° C., an appropriate amount of water, and manganese source (specifically manganese oxide), iron source (specifically iron oxalate), magnesium doping metal source (specifically magnesium oxide) and phosphorus source (specifically Phosphoric acid) according to the molar ratio of 0.8:0.15:0.05:1.0, after 1 hour, add lithium source (specifically lithium carbonate) and mix, and the molar ratio of lithium source and phosphorus source is 1.02:1.00, then add an appropriate amount of carbon source, specifically glucose, to obtain a blend. The blend was milled in a ball mill for 4 hours to obtain a milled blend. The ground blend was then spray-dried with a spray granulator (the air inlet temperature of the spray granulator was controlled at 200°C) to obtain a granulated mixture. The granulation mixture was placed in a bell furnace, and under a nitrogen atmosphere, the granulation mixture was subjected to a preliminary si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com