Layered and tunnel-shaped mixed structure sodium ion battery positive electrode material and a preparation method thereof and a sodium ion battery

A technology for sodium ion batteries and positive electrode materials, which is applied in battery electrodes, chemical instruments and methods, and electrolyte battery manufacturing, etc., can solve problems such as poor cycle performance and low specific capacity, and achieve easy raw materials, simple preparation methods, and easy large-scale production. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

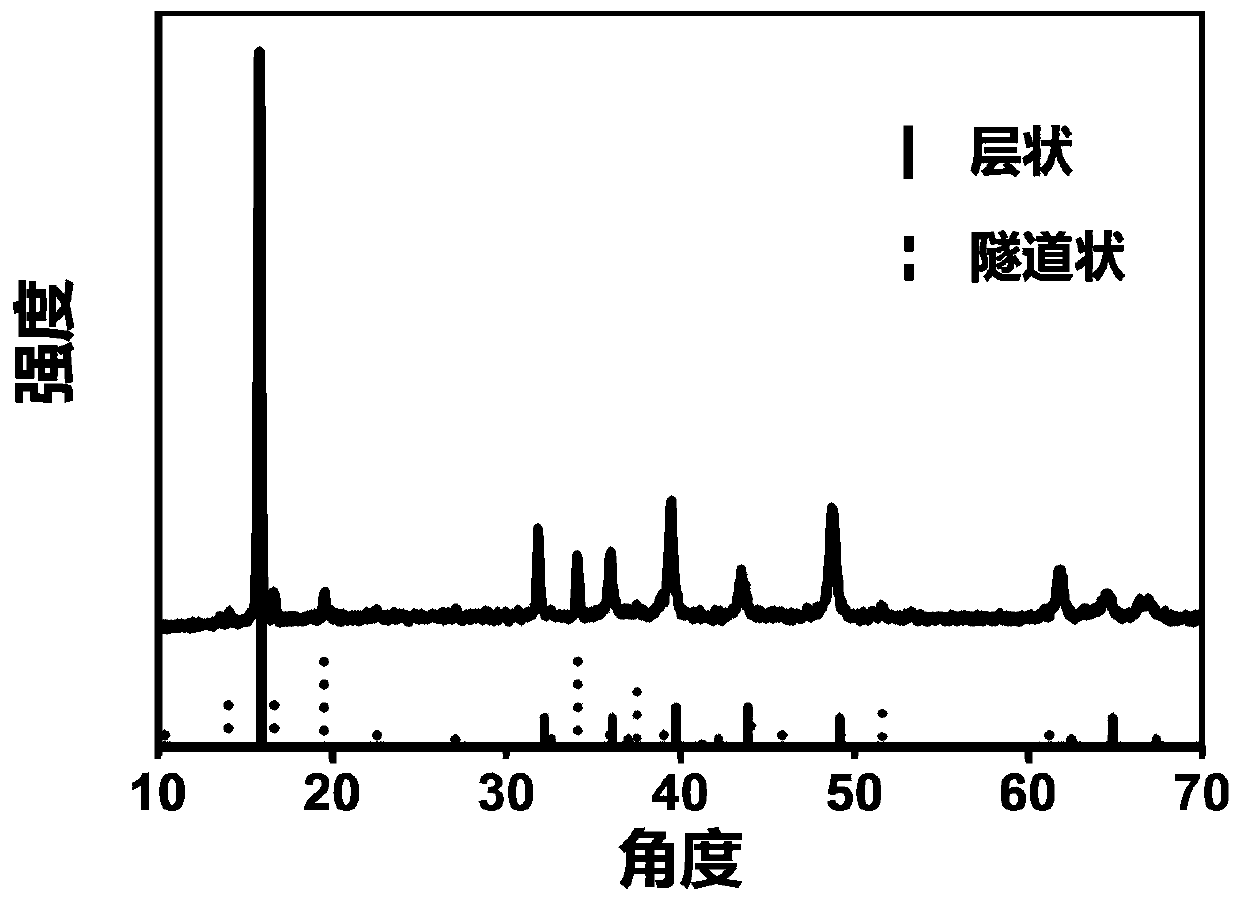

[0052] The invention provides a method for preparing a layered and tunnel-like mixed structure of a sodium ion battery cathode material, which includes:

[0053] Mix the sodium source, iron source and manganese source according to the molar ratio, and grind to obtain a mixed powder;

[0054] Calcining the mixed powder for the first time to obtain an intermediate product;

[0055] The intermediate product is ground and then calcined for the second time to obtain a sodium ion battery cathode material.

[0056] The present invention firstly mixes the sodium source, iron source and manganese source according to the molar ratio and grinds to obtain mixed powder;

[0057] Wherein, the molar ratio of the sodium source, iron source and manganese source is 0.6:0.04:0.96.

[0058] According to the present invention, the sodium source is preferably selected from one or more of sodium acetate, sodium nitrate, sodium oxalate and sodium citrate; more preferably from sodium acetate or sodium nitrate; m...

Embodiment 1

[0086] Example 1 Preparation of Na 0.6 Fe 0.04 Mn 0.96 O 2 Electrode material

[0087] The target product is Na 0.6 Fe 0.04 Mn 0.96 O 2 , Raw materials include sodium acetate, iron nitrate, and manganese acetate.

[0088] The raw material metal salt is weighed according to a molar ratio of 0.6:0.04:0.96, and then ground into a uniformly mixed powder with a mortar. The powder obtained by preliminary grinding is placed in a muffle furnace, and the heating rate is 1 degree per minute, and the intermediate product is calcined at 450 degree for 6 hours in an air atmosphere. The intermediate product after the first calcination is subjected to secondary grinding and then placed in a muffle furnace, and the target product Na is obtained by calcining at 900 degrees in an air atmosphere at a heating rate of 2 degrees per minute for 15 hours. 0.6 Fe 0.04 Mn 0.96 O 2 .

Embodiment 2

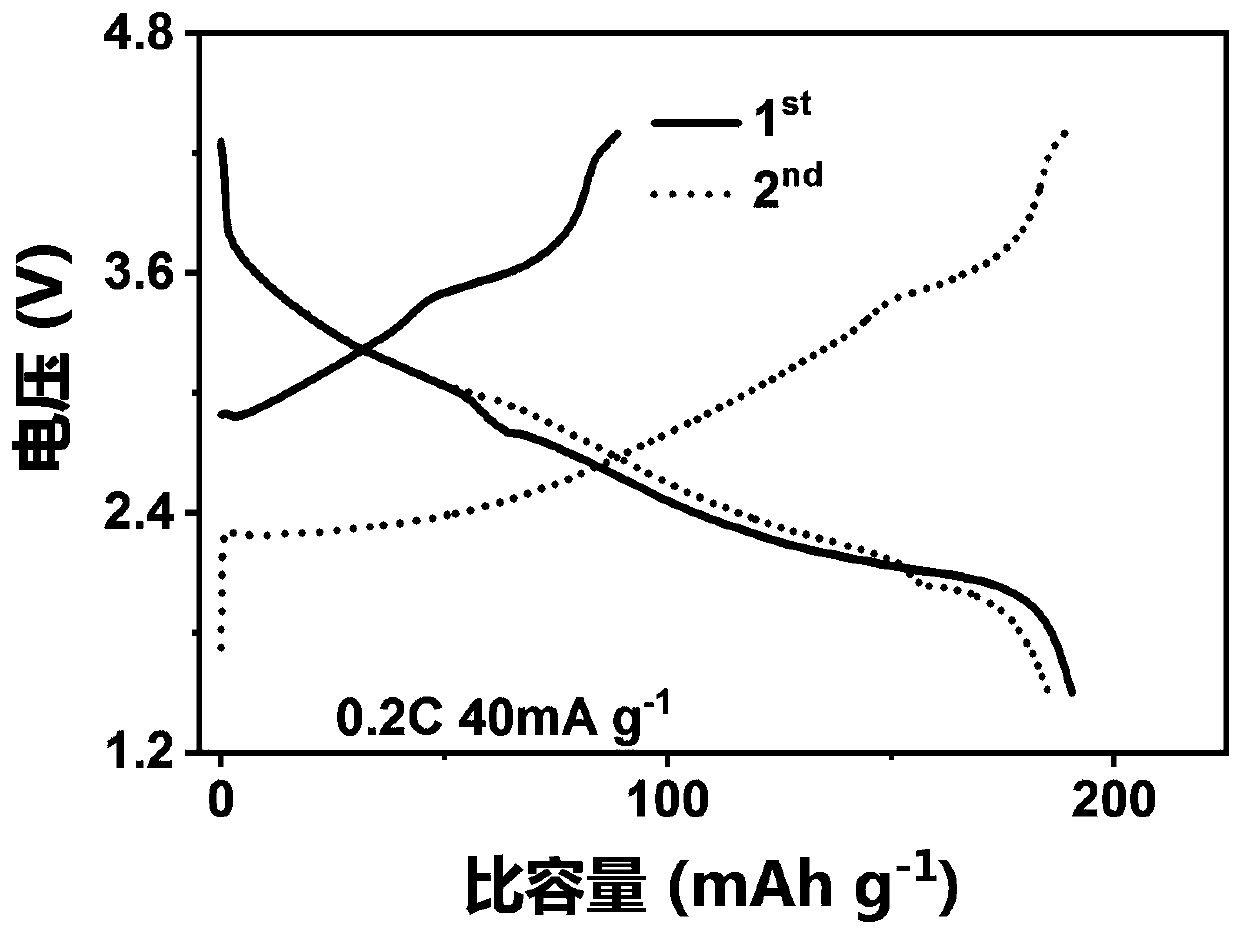

[0089] Example 2 Preparation of Na 0.6 Fe 0.04 Mn 0.96 O 2 Cathode material electrode sheet

[0090] The target product prepared in Example 1 of the present invention is mixed with Super P and the binder polyvinylidene fluoride in a mass ratio of 7:2:1, and the solvent N-methylpyrrolidone is added, after pulping, smearing, drying, etc. After the steps, an electrode sheet containing the target product oxide cathode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com