Magnesium-based hydrogen storage alloy material and preparation method thereof

A magnesium-based hydrogen storage alloy and amorphous alloy technology, applied in the field of hydrogen storage, can solve the problems of exhaustion of improvement effect, neglect of mutual coordination, and neglect of the interaction between the active layer and magnesium-based hydrogen storage alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

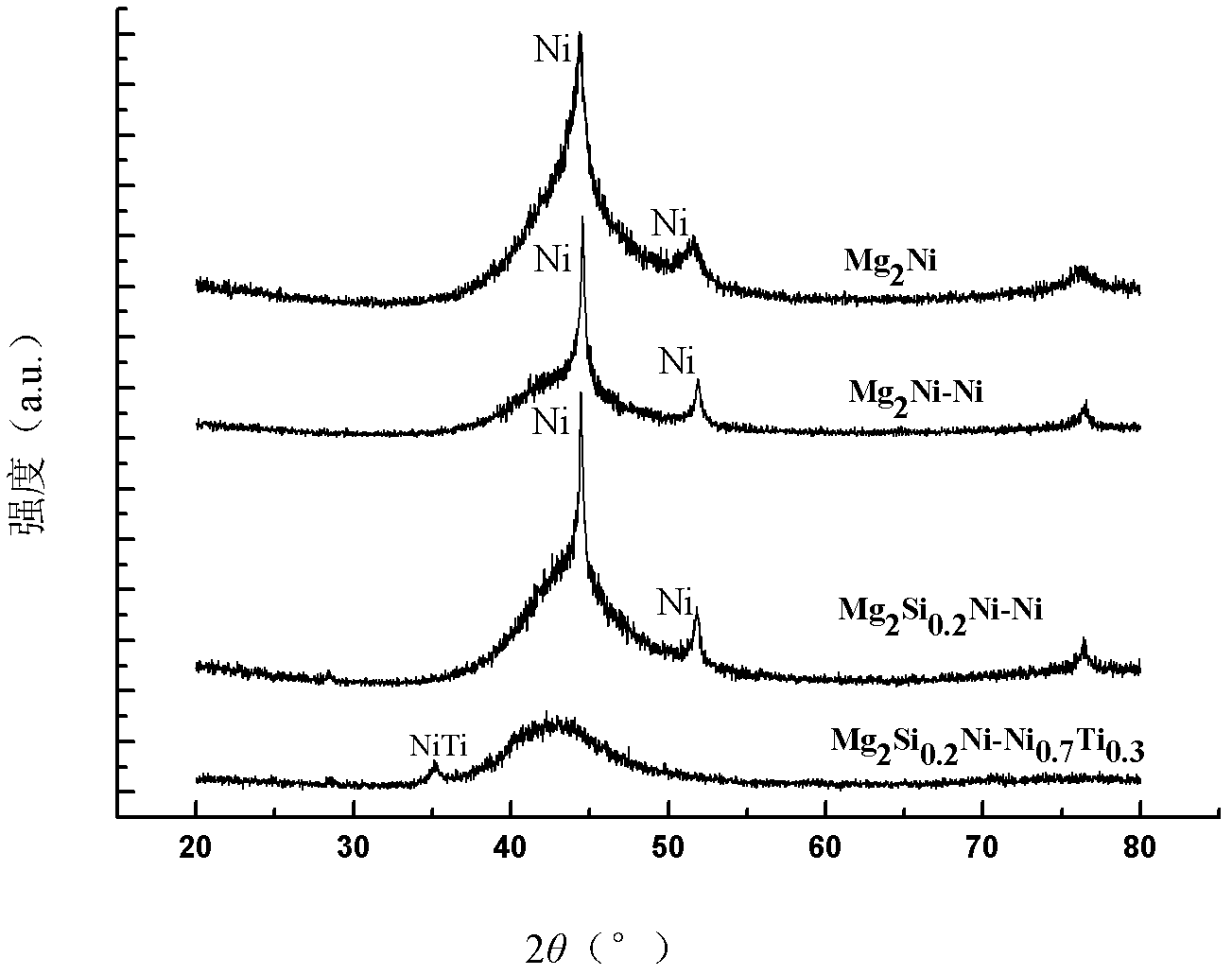

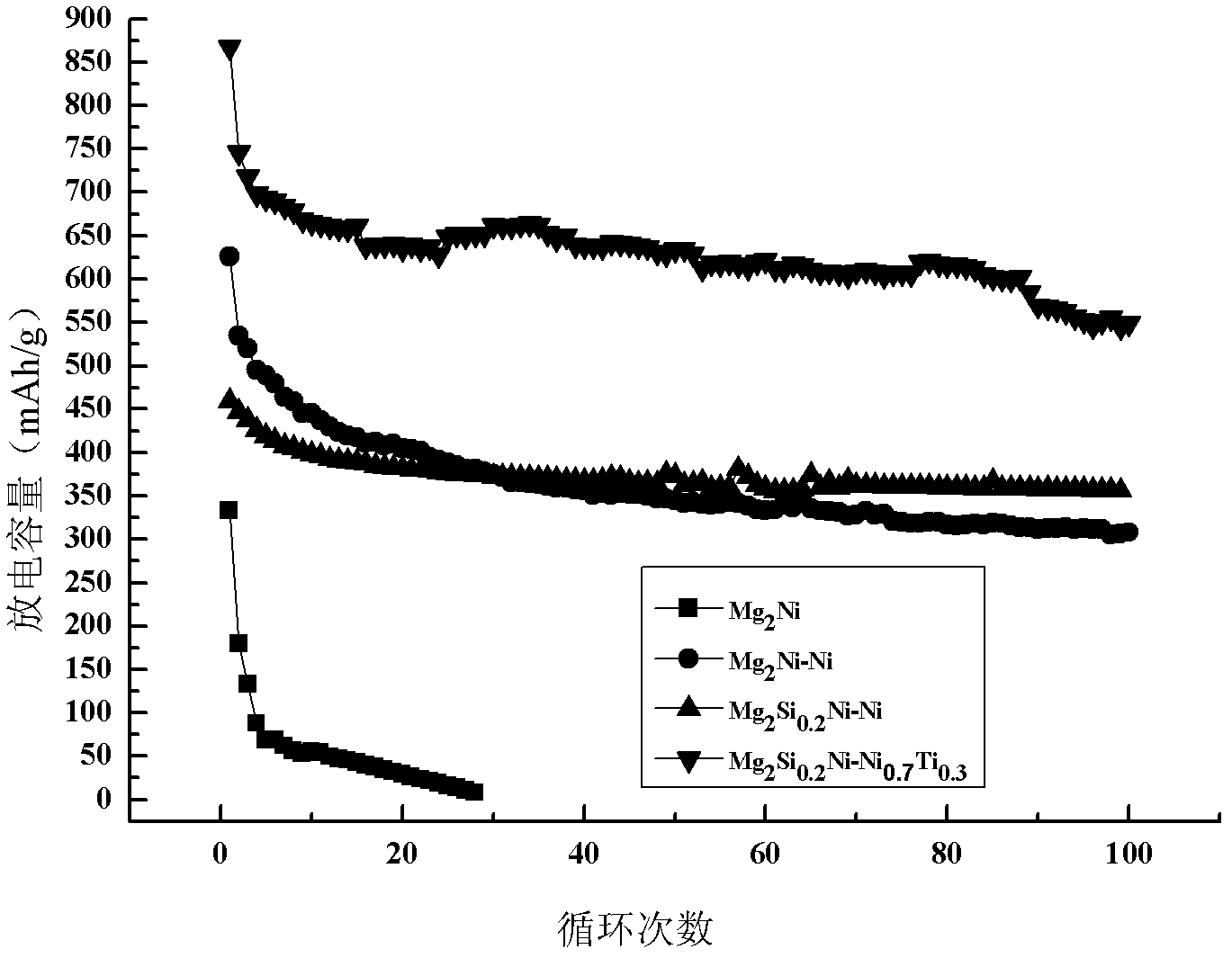

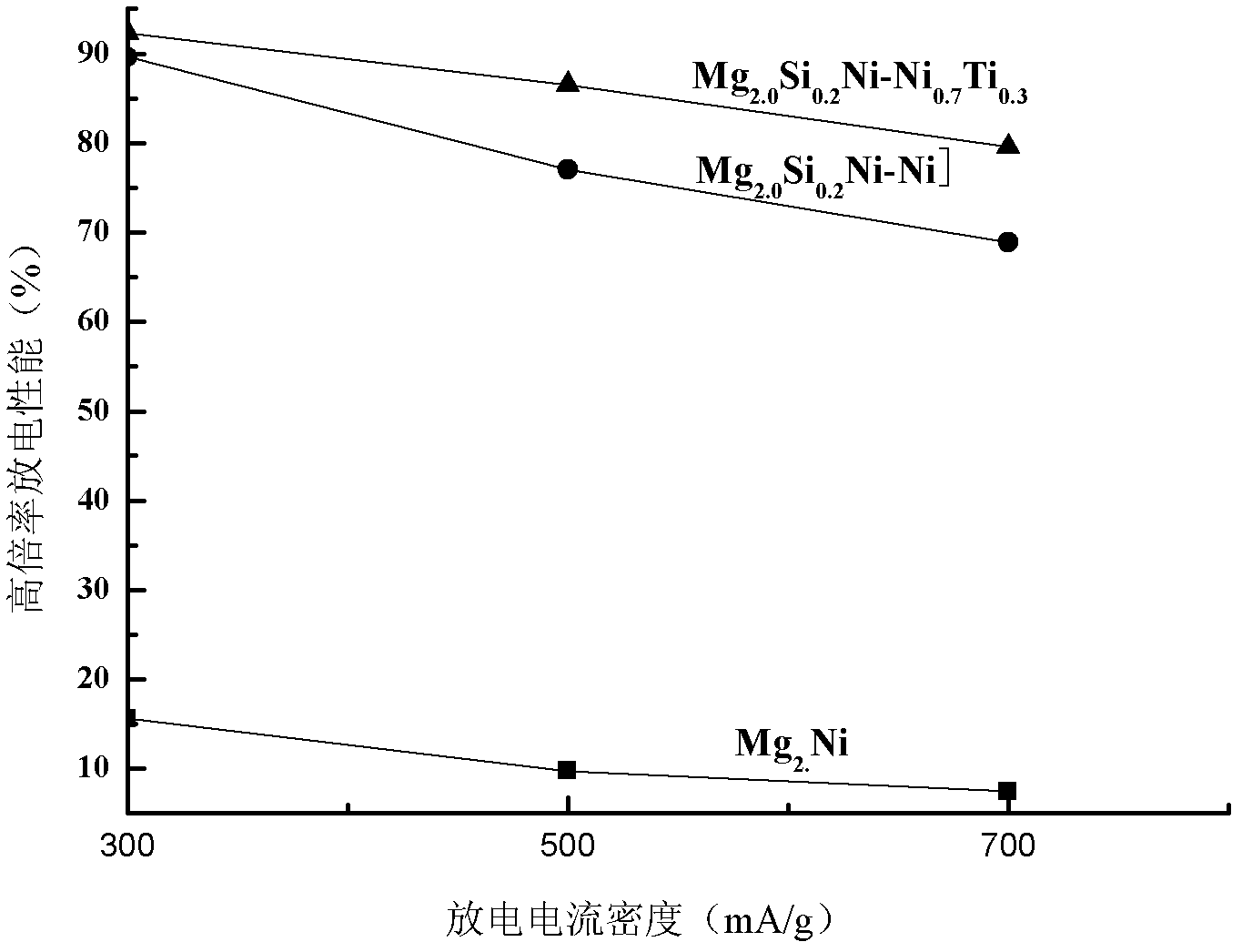

[0034] Press Mg, Si, Ni powder into Mg 2.0 Si 0.2 The stoichiometric ratio of Ni is evenly mixed, and it is packed into a stainless steel vacuum spherical tank with a volume of 100ml, and stainless steel balls are put into the steel balls at a weight ratio of 1:20 by material: steel balls. Before ball milling, the ball mill tank should be evacuated and filled with 1.0×10 5 Pa argon to prevent the alloy metal powder from being oxidized. The rotational speed of the ball mill was 500 rpm. The ball milling time was 80 hours. The working system adopts intermittent rotation to prevent the recrystallization of the amorphous alloy due to excessive temperature rise. Take out Mg 2.0 Si 0.2 Ni alloy powder, by (Mg 2.0 Si 0.2 Ni) 40wt%, (Ni 0.7 Ti 0.3 ) 60wt% ratio to add Ni and Ti powders, mix evenly, add to the stainless steel grinding jar, first vacuumize the ball mill jar, and fill it with 1.0×10 5 Pa of argon to prevent the alloy powder from being oxidized. The rotating s...

Embodiment 2

[0037] Mg, Si, Ni metal powder by Mg 1.8 Si 0.2 The stoichiometric ratio of Ni is evenly mixed, and it is packed into a stainless steel vacuum spherical tank with a volume of 100ml, and stainless steel balls are put into the steel balls at a weight ratio of 1:20 by material: steel balls. Before ball milling, the ball mill tank should be evacuated and filled with 1.0×10 5 Pa argon to prevent the alloy metal powder from being oxidized. The rotational speed of the ball mill was 450 rpm. The ball milling time was 80 hours. The working system adopts intermittent rotation to prevent the recrystallization of the amorphous alloy due to excessive temperature rise. Take out Mg 1.8 Si 0.2 Ni alloy powder, by (Mg 1.8 Si 0.2 Ni) 40wt%, (Ni 0.7 Ti 0.15 B 0.15 ) in a ratio of 60wt% to add powder, mix evenly, add to the stainless steel grinding jar, first vacuumize the ball mill jar, and fill it with 1.0×10 5 Pa of argon to prevent the alloy powder from being oxidized. The rotati...

Embodiment 3

[0040] Mg, Zr, Ni metal powder by Mg 1.8 Zr 0.2 The stoichiometric ratio of Ni is evenly mixed, and it is packed into a stainless steel vacuum spherical tank with a volume of 100ml, and stainless steel balls are put into the steel balls at a weight ratio of 1:20 by material: steel balls. Before ball milling, the ball mill tank should be evacuated and filled with 1*.0×10 5 Pa argon to prevent the alloy metal powder from being oxidized. The rotational speed of the ball mill was 450 rpm. The ball milling time was 80 hours. The working system adopts intermittent rotation to prevent the recrystallization of the amorphous alloy due to excessive temperature rise. Take out Mg 1.8 Zr 0.2 77 Ni alloy powder, by (Mg 1.8 Zr 0.2 Ni) 40wt%, (Ni 1.1 Ti 0.4 ) with a ratio of 60wt% to add Ni and Ti powders, mix well, and add them into a stainless steel grinding jar. Vacuum the ball mill tank first, and fill it with 1.0×10 5 Pa argon to prevent the alloy metal powder from being oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com