High-capacity hydrogen storage film and preparation method thereof

A high-capacity, thin-film technology, applied in vacuum evaporation plating, coating, sputtering plating, etc., can solve the problems of low hydrogen absorption and desorption temperature, poor stability and cycle stability, and high hydrogen absorption and desorption temperature, and achieves high absorption and desorption. The effect of fast hydrogen rate, good application prospect and high electrochemical discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

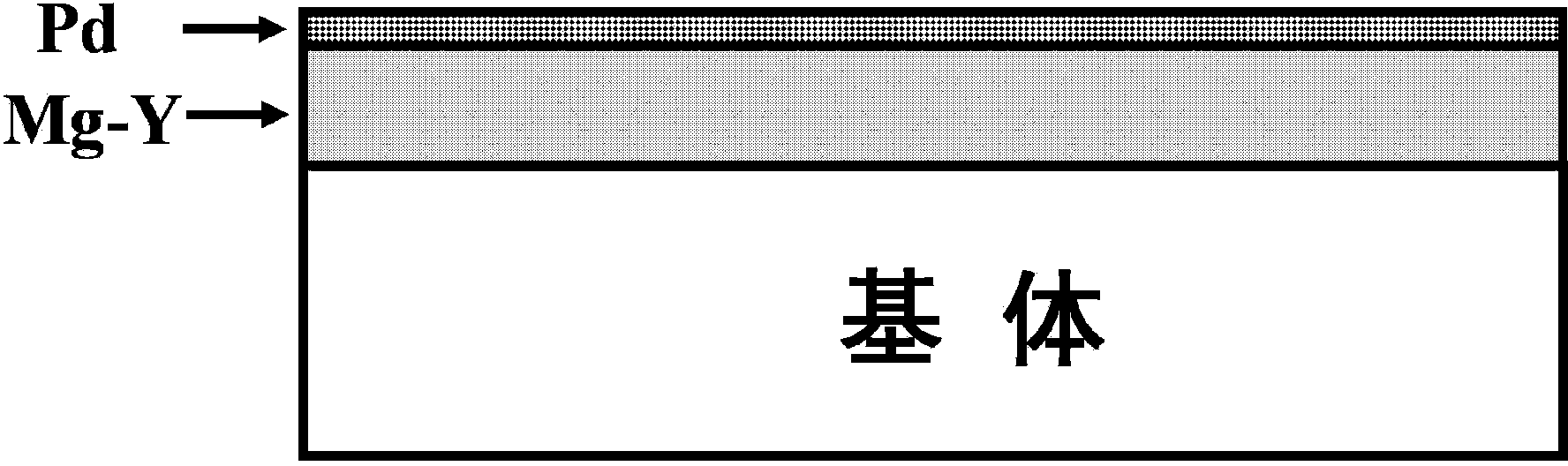

[0034] Embodiment 1, preparation 100nm is covered with the Mg of Pd layer 78 Y 22 film

[0035] The first step, substrate cleaning

[0036] Choose ordinary glass as the substrate. Before sputtering, the glass substrate was ultrasonically cleaned in deionized water, acetone and ethanol solutions for 15 minutes to remove surface impurities, and then the substrate was allowed to air dry naturally.

[0037] The second step, film preparation

[0038] Put the air-dried glass substrate into the chamber of the magnetron sputtering apparatus, and evacuate to 2×10 -4 Pa.

[0039] Argon gas was introduced into the chamber of the magnetron sputtering apparatus, and the thin film was prepared by co-sputtering with Mg and Y targets by magnetron sputtering. The specific sputtering conditions are: the background vacuum is 2×10 -4 Pa; the flow rate of argon gas is 76 sccm; the working pressure of argon gas is 0.6 Pa; the substrate temperature is 25°C; the sputtering powers of Mg and Y a...

Embodiment 2

[0041] Embodiment 2, preparation 100nm thick Mg covered with Pd layer 37 Y 63 film

[0042] The first step, substrate cleaning

[0043] In this method, a quartz plate is selected as the substrate. Before sputtering, the quartz slices were ultrasonically cleaned in deionized water, acetone and ethanol solutions for 15 minutes to remove surface impurities. Then wait for the substrate to dry naturally, put it into the chamber of the magnetron sputtering apparatus, and evacuate to 2×10 -4 Pa.

[0044] The second step, film preparation

[0045]Argon gas was introduced into the chamber of the magnetron sputtering apparatus, and the thin film was prepared by co-sputtering with Mg and Y targets by magnetron sputtering. The specific sputtering conditions described are: the background vacuum is 2×10 -4 Pa; the flow rate of argon gas is 76 sccm; the working pressure of argon gas is 0.6 Pa; the substrate temperature is 25°C; the sputtering powers of Mg and Y are 14W and 45W, respec...

Embodiment 3

[0047] Embodiment 3, prepare 100nm thick Mg covered with Pd layer 28 Y 72 film

[0048] The first step, substrate cleaning

[0049] In this method, a silicon wafer is selected as the substrate. Before sputtering, silicon wafers were ultrasonically cleaned in deionized water, acetone, and ethanol solutions for 15 minutes to remove surface impurities. Then wait for the substrate to dry naturally, put it into the chamber of the magnetron sputtering apparatus, and evacuate to 2×10 -4 Pa.

[0050] The second step, film preparation

[0051] Argon gas was introduced into the chamber of the magnetron sputtering apparatus, and the thin film was prepared by co-sputtering with Mg and Y targets by magnetron sputtering. The specific sputtering conditions described are: the background vacuum is 2×10 -4 Pa; the flow rate of argon gas is 76 sccm; the working pressure of argon gas is 0.6 Pa; the substrate temperature is 25°C; the sputtering powers of Mg and Y are 14W and 60W, respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com