Nano lithium titanate for Negative electrode material of cell or electrochemical vessel, and its and titanium dioxide composite preparing method

A technology of nano-lithium titanate and titanium dioxide, which is applied in the field of nano-materials, can solve the problems of difficulty in large-scale industrial production, large volume changes of alloy-type negative electrodes, and complicated preparation methods of carbon materials, and achieve good cycle stability and excellent electrochemical performance. , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

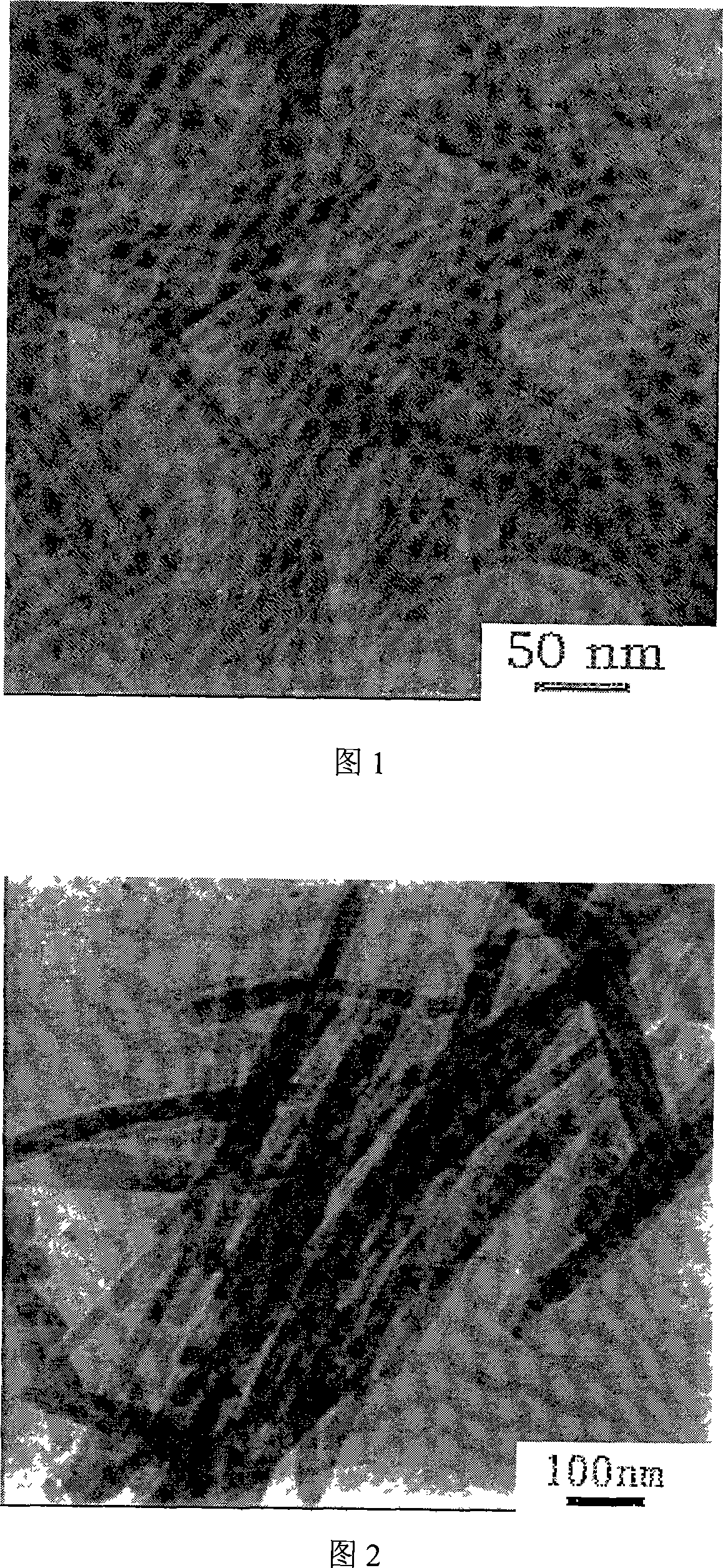

[0031] Embodiment 1, get 3g TiO 2 , slowly add 300ml of NaOH solution with a concentration of 3mol / L into a polytetrafluoroethylene container, control the temperature at 120°C, stir and add a reflux condenser, react for 24 hours to obtain nanotube sodium titanate, wash the above titanate Sodium nanotubes to a pH of 13, then suction filtered, dried, mixed with 12g of lithium nitrate and ground, melted and heated at 500°C for 2.5 hours, washed and dried to obtain a spinel lithium titanate product; as shown in Figure 1, The diameter of the nano-lithium titanate is about 8-10nm, and the length is about 100nm.

Embodiment 2

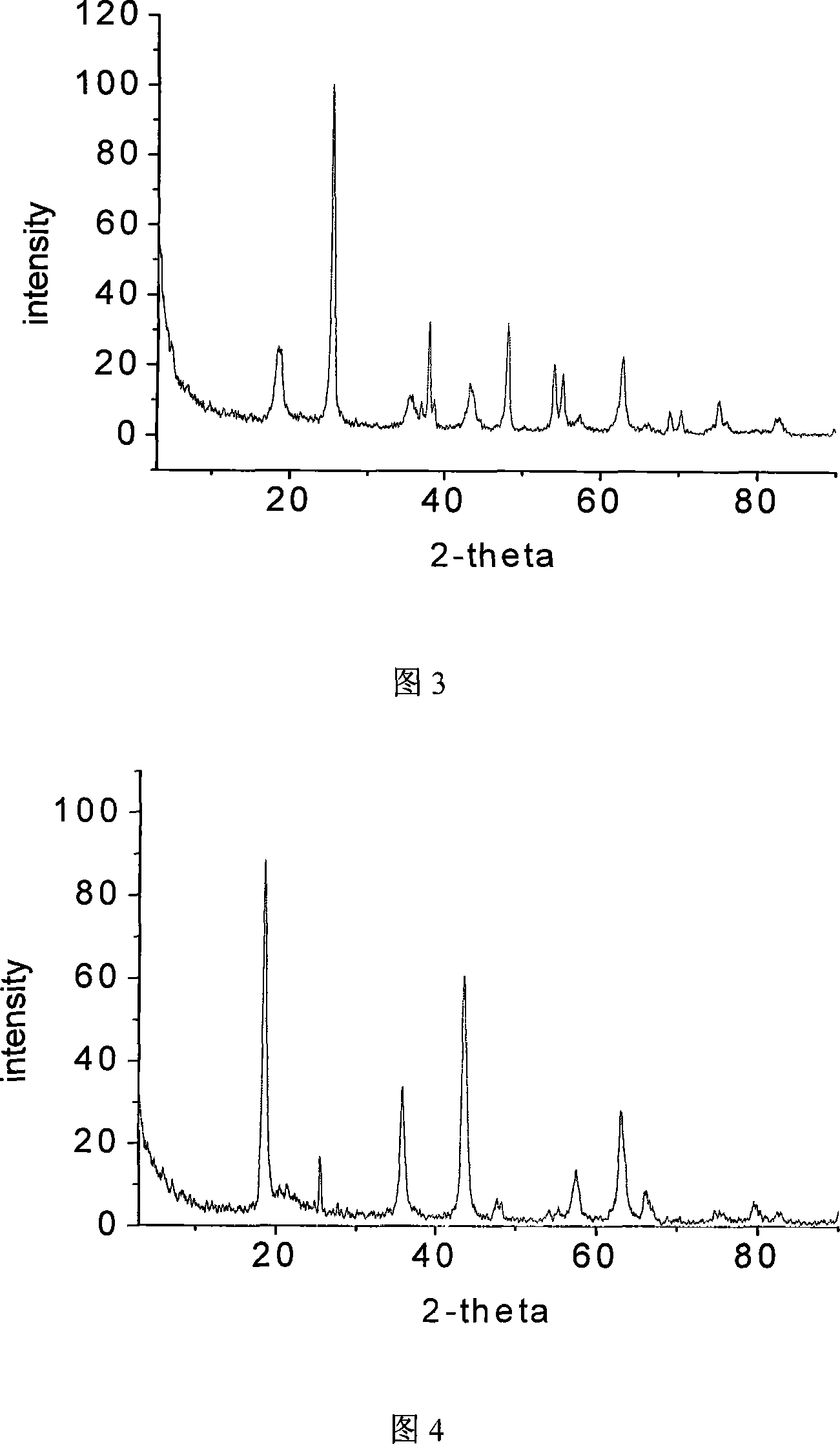

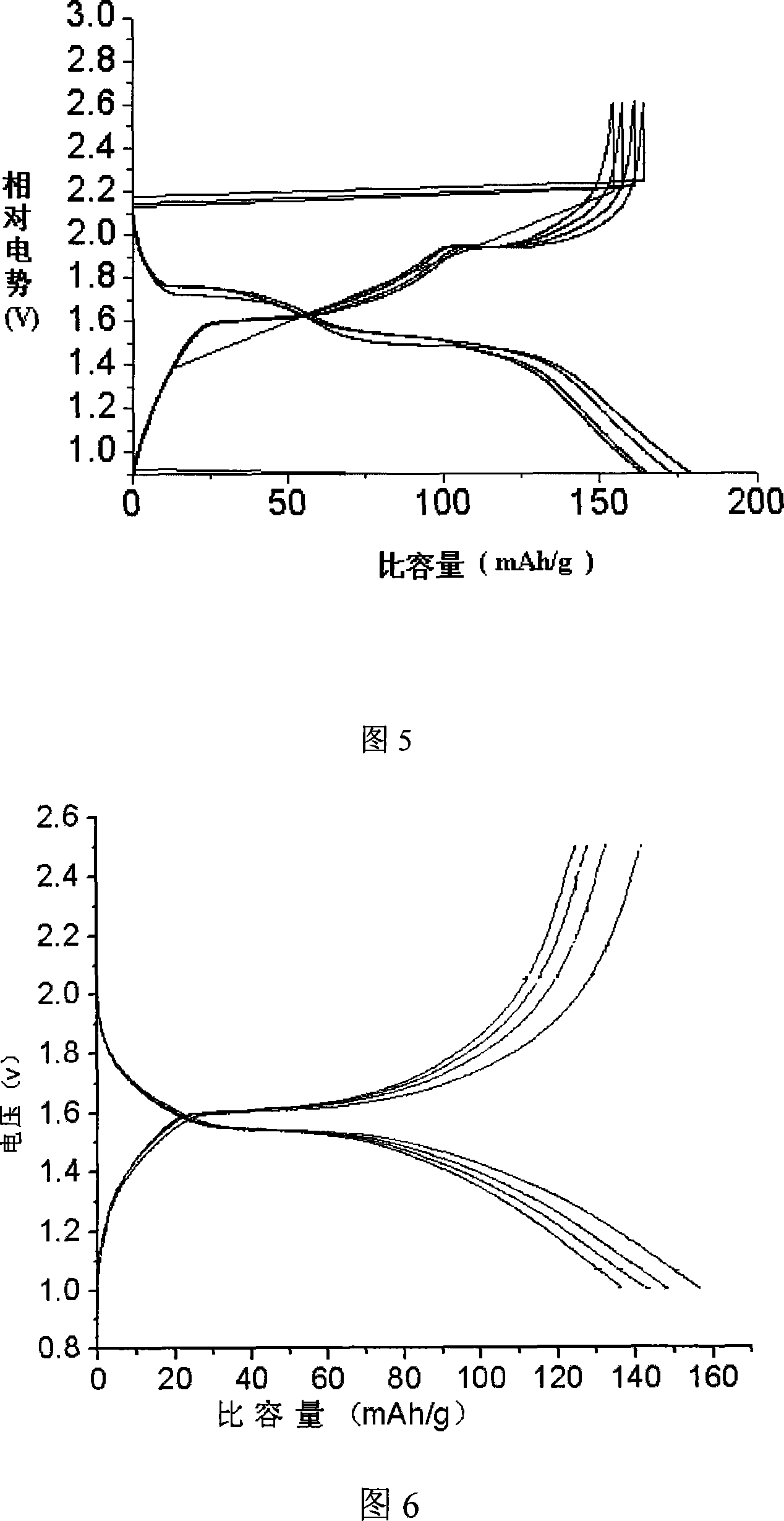

[0032] Example 2, get 10g of metatitanic acid (industrial slurry, weight content 44.04%, produced by Yida Fine Chemical Co., Ltd.), and slowly add 100ml of KOH solution with a concentration of 10mol / L into a polytetrafluoroethylene reaction vessel, Put it in a microwave oven, set it to medium-low heat (750W, work for 10s, stop for 12s), mechanically stir, add a reflux condenser, react for 6 hours to get potassium titanate nanowires with a diameter of several nanometers, wash until the pH is 7 and dry , and then take 25g of lithium citrate and lithium chloride mixture (weight ratio is 1:3) mixed with dried potassium titanate / titanic acid composite fiber, and put it in a sintering furnace, under the protection of nitrogen, melt and heat at 1000°C Exchanged for 2 hours, the lithium titanate-titanium dioxide composite was obtained, the morphology of which is shown in Figure 2; the crystal structure is shown in Figure 3, which contains two different crystal forms: cubic spinel struc...

Embodiment 3

[0033] Embodiment 3, get 3g TiO 2 , slowly add 300ml of NaOH solution with a concentration of 10mol / L into a polytetrafluoroethylene container, control the temperature at 120°C, stir and add a reflux condenser, react for 24 hours to obtain nanotube sodium titanate, wash the above titanate Sodium nanotubes to a pH of 6, then suction filtered and dried; then ground with a mixture of 5 g of lithium hydroxide and lithium nitrate (1:5 by weight), melted, heated and exchanged at 451°C for 48 hours, washed and dried to obtain the product Composite of spinel lithium titanate and titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com