Application of CuCl/Cu composite material

A composite material and current collector technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of reducing electrode cycle charge/discharge life, insufficient combination of active material and current collector, pulverization and shedding, etc. Achieve good charge-discharge cycle stability, improve cycle stability, and increase discharge specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

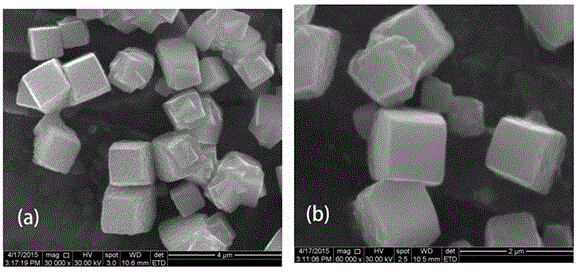

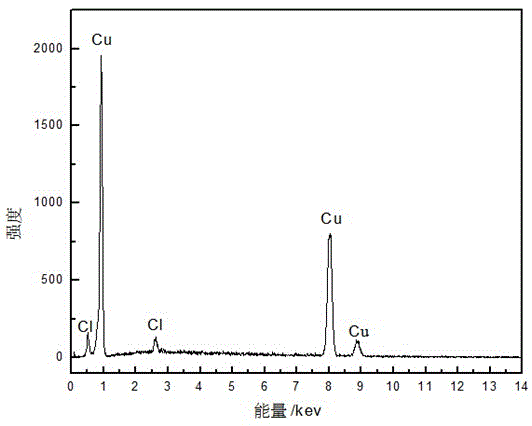

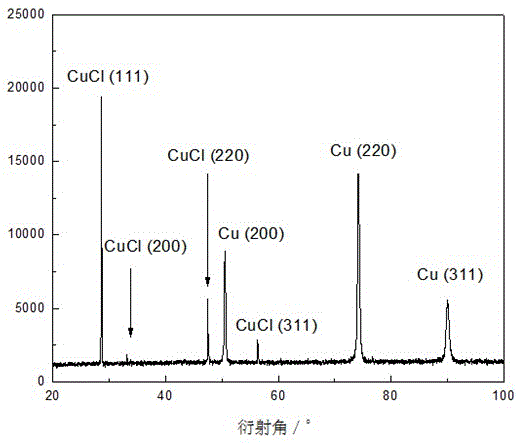

[0023] Using 0.1mol / L sodium chloride aqueous solution with pH=5 as the electrolyte solution, copper foil as the working electrode, platinum sheet as the counter electrode, constant current (5mA / cm 2 ) anodized for 60s, rinsed and dried under vacuum at 25°C to obtain CuCl / Cu composites.

[0024] The prepared CuCl / Cu composite material was directly used as the working electrode, the lithium foil was used as the counter electrode and the reference electrode, and the Celgard2500 film was used as the diaphragm, and the 1MLiPF 6 The mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and dimethyl carbonate (DMC) is the electrolyte, wherein the volume ratio of EC, DEC and DMC is 1:1:1, and then filled with A button-type simulated lithium-ion battery is assembled with lithium foil in a high-purity argon glove box, and its charge / discharge performance and cycle stability are tested by a constant current charge / discharge method.

Embodiment 2

[0026] Using 0.1mol / L sodium chloride aqueous solution with pH=5 as the electrolyte solution, copper foil as the working electrode, platinum sheet as the counter electrode, constant current (5mA / cm 2 ) anodized for 120s, rinsed and dried under vacuum at 25°C to obtain CuCl / Cu composites.

[0027] Without adding additional conductive agent and binder, the CuCl / Cu composite material is directly used as the working electrode, the lithium foil is used as the counter electrode and the reference electrode, and the Celgard2400 film is used as the separator. 6 The mixture of ethylene carbonate (EC) and diethyl carbonate (DEC) is the electrolyte solution, wherein the volume ratio of EC and DEC is 1:1, and then assembled with lithium foil in a glove box filled with high-purity argon A button-type simulated lithium-ion battery, and its charge / discharge performance is tested by a constant current charge / discharge method ( Figure 4 ) performance and cycle stability ( Figure 5 ), it can...

Embodiment 3

[0029] Use 0.06mol / L potassium chloride aqueous solution with pH = 7 as the electrolyte solution, in which the working electrode is copper foil, the counter electrode is platinum sheet electrode, constant current (5mA / cm 2 ) anodized for 240s, rinsed and dried in vacuum at 40°C to obtain CuCl / Cu composites.

[0030] Without adding additional conductive agent and binder, the CuCl / Cu composite material is directly used as the working electrode, the lithium foil is used as the counter electrode and the reference electrode, the Celgard2325 film is used as the separator, and the 1MLiPF 6 The mixture of ethylene carbonate (EC), diethyl carbonate (DEC) and dimethyl carbonate (DMC) is the electrolyte, in which the volume ratio of EC, DEC and DMC is 1:1:1, filled with high-purity A button-type simulated lithium-ion battery is assembled in an argon glove box, and its charge / discharge performance and cycle stability are tested by a constant current charge / discharge method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com