Flexible zinc-air battery based on polymer electrolyte

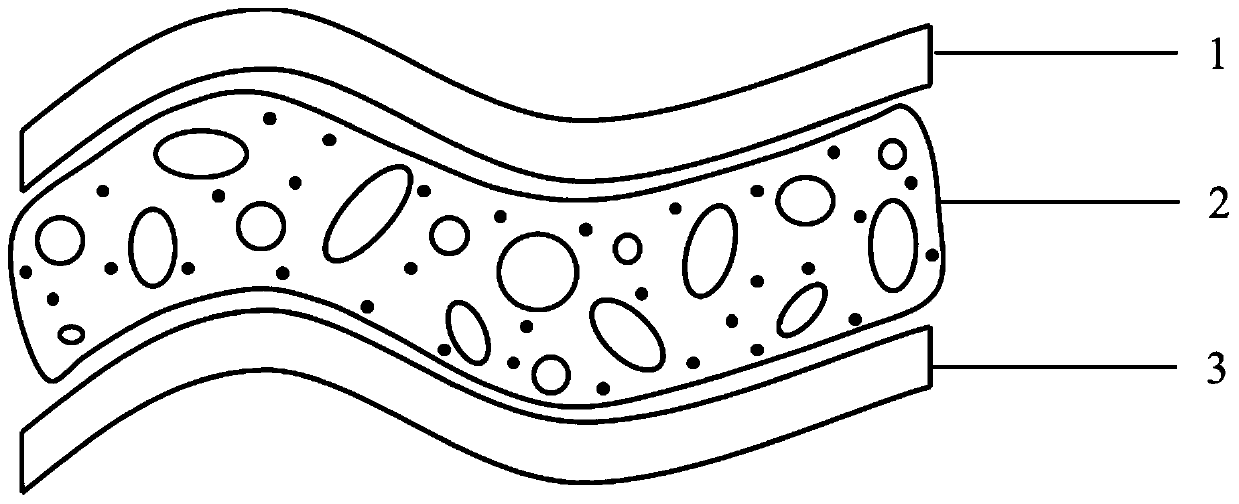

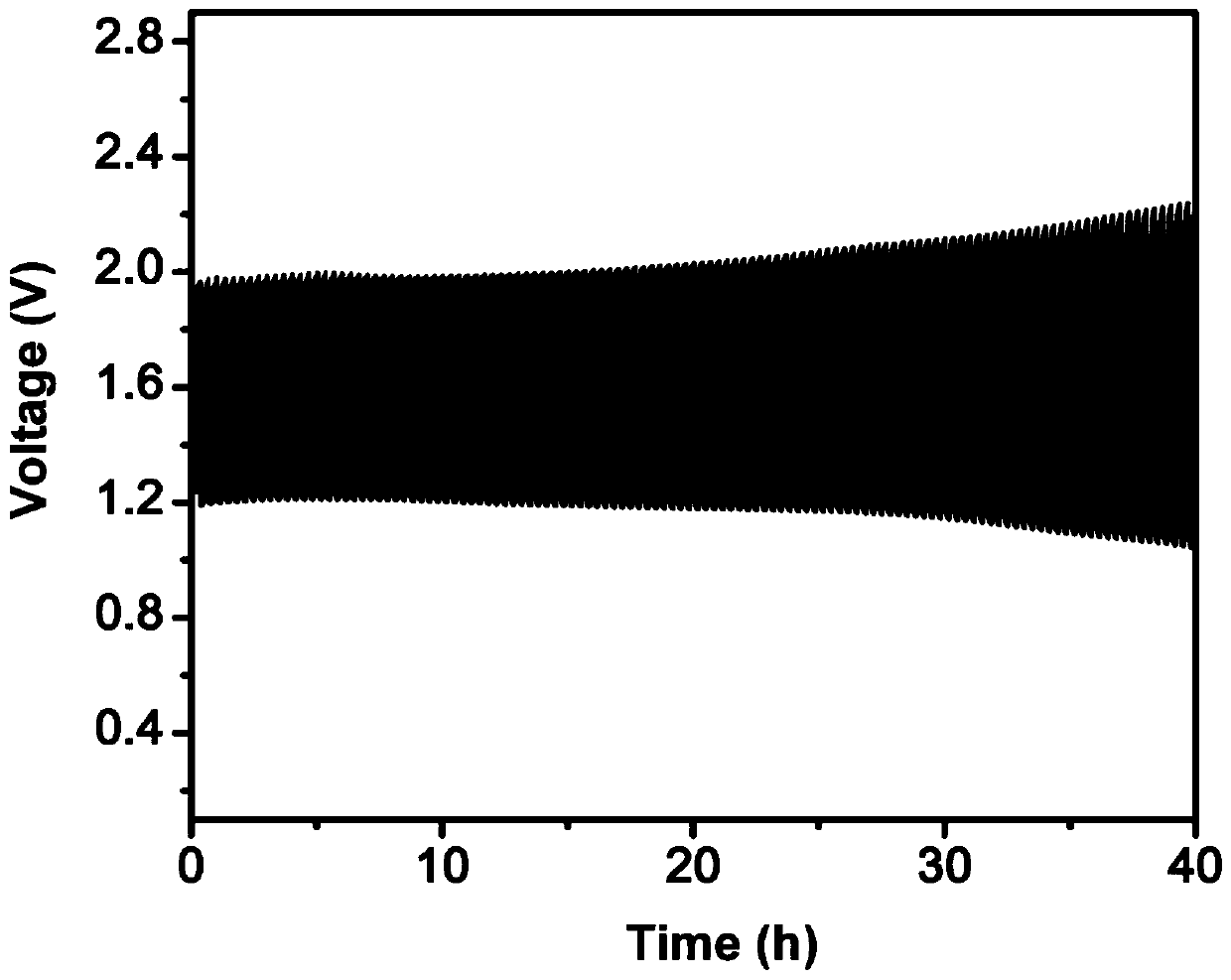

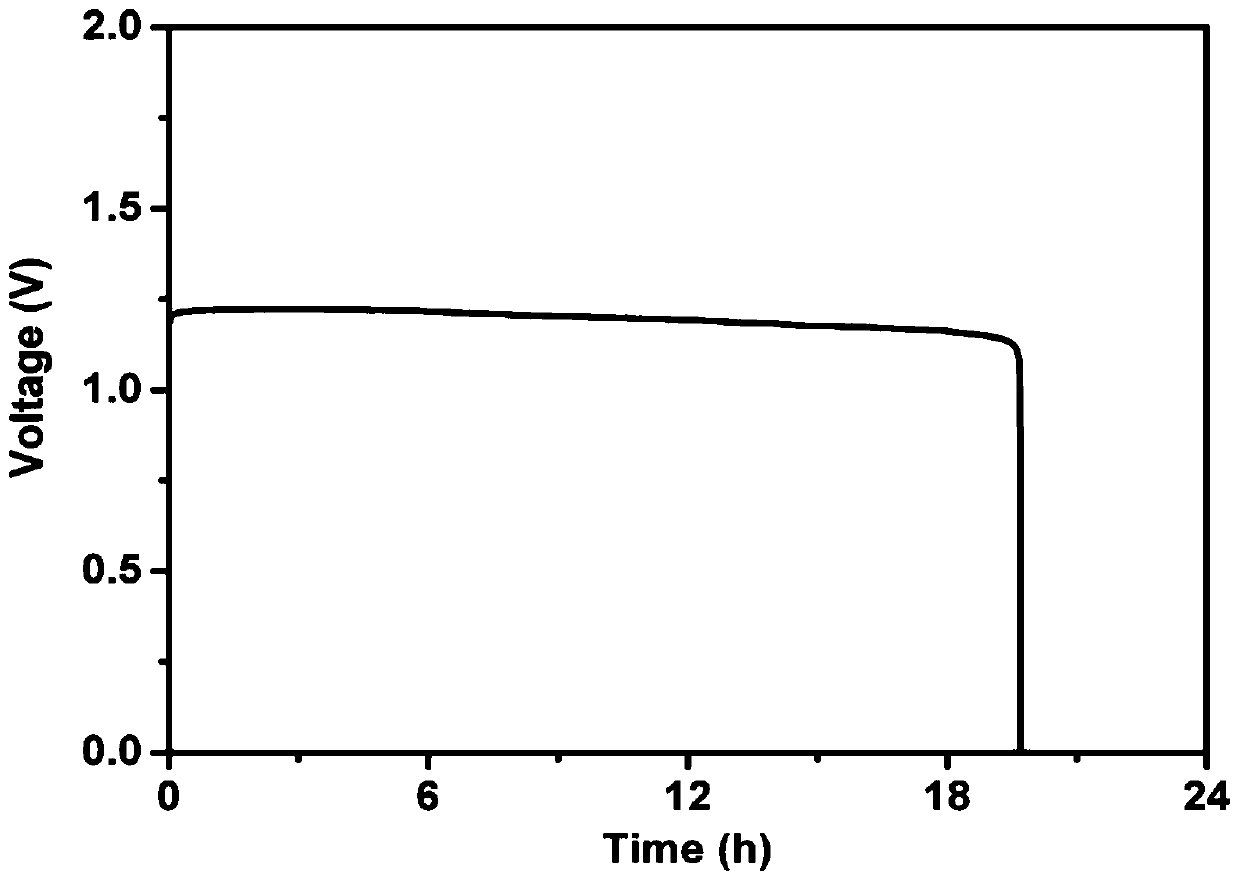

A zinc-air battery, polymer technology, applied in nanotechnology for materials and surface science, fuel cell-type half-cell and primary battery-type half-cell, nanotechnology, etc., can solve the problem of poor moisture retention and poor liquid absorption , low ionic conductivity and other problems, to achieve the effects of excellent flexibility, excellent charge-discharge cycle stability, liquid electrolyte absorption rate and electrolyte retention rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a method for preparing a flexible zinc-air battery based on a polymer electrolyte, the steps of which are as follows:

[0038] (1) Preparation of cobalt tetraoxide / carbon cloth positive electrode: the carbon cloth was washed with acetone and deionized water in an ultrasonic cleaner for 30 min before use, and then fully dried in a constant temperature drying oven for use. Cobalt tetroxide slurry is made of 9mg of cobalt tetroxide powder and 21mg of carbon black, to which 2.4mL of deionized water, 0.6mL of isopropanol and 0.3mL of Put the perfluororesin solution in the ultrasonic cleaner for 30 minutes and take it out for use. The prepared cobalt tetroxide slurry was coated dropwise on carbon cloth with a pipette gun and dried at room temperature with a loading capacity of 0.3 mg cm –2 .

[0039](2) Preparation of flexible polymer electrolyte: First, weigh a certain amount (equivalent to 5wt.% polyvinyl alcohol) of nano-silica powder with a p...

Embodiment 2

[0044] This embodiment relates to a method for preparing a flexible zinc-air battery based on a polymer electrolyte, the steps of which are as follows:

[0045] (1) Preparation of cobalt tetraoxide / carbon cloth positive electrode: the carbon cloth was washed with acetone and deionized water in an ultrasonic cleaner for 30 min before use, and then fully dried in a constant temperature drying oven for use. Cobalt tetroxide slurry is made of 8.5mg of cobalt tetroxide powder and 20.5mg of carbon black, to which 2.3mL of deionized water, 0.55mL of isopropanol and 0.25mL of Put the perfluororesin solution in the ultrasonic cleaner for 40 minutes and take it out for use. The prepared cobalt tetroxide slurry was coated dropwise on carbon cloth with a pipette gun and dried at room temperature with a loading capacity of 0.25 mg cm -2 .

[0046] (2) Preparation of flexible polymer electrolyte: First, weigh a certain amount (equivalent to 1wt.% polyacrylic acid) of nano-silica powder w...

Embodiment 3

[0051] This embodiment relates to a method for preparing a flexible zinc-air battery based on a polymer electrolyte, the steps of which are as follows:

[0052] (1) Preparation of cobalt tetraoxide / carbon cloth positive electrode: the carbon cloth was washed with acetone and deionized water in an ultrasonic cleaner for 30 min before use, and then fully dried in a constant temperature drying oven for use. Cobalt tetroxide slurry is made of 9.5mg of cobalt tetroxide powder and 21.5mg of carbon black, to which 2.5mL of deionized water, 0.65mL of isopropanol and 0.35mL of Put the perfluororesin solution in the ultrasonic cleaner for 35 minutes and take it out for use. The prepared cobalt tetroxide slurry was coated dropwise on carbon cloth with a pipette gun and dried at room temperature, and its loading capacity was 0.35 mg cm -2 .

[0053] (2) Preparation of flexible polymer electrolyte: First, weigh a certain amount (equivalent to 9wt.% polyvinyl alcohol) of nano-silica powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com