Preparation method of carbon nanotube/silica/carbon composite cathode material

A technology of carbon nanotubes and silicon dioxide, which is applied in the preparation of negative electrode active materials carbon nanotubes/silicon dioxide/carbon composite materials and the preparation of lithium-ion battery electrode materials, can solve problems such as poor cycle stability, Achieve excellent charge-discharge cycle stability, moderate conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to absolute ethanol: the volume ratio of deionized water is 1:5 to configure ethanol solution, according to cetyltrimethylammonium bromide: ethanol solution mass ratio is 1:200 to cetyltrimethyl bromide Ammonium is dissolved in ethanol solution, and lithium hydroxide is added to the above solution while stirring, and the mass ratio of cetyltrimethylammonium bromide:lithium hydroxide is 5:1. After thorough stirring, add carbon nanotubes into the above solution according to the ratio of carbon nanotubes: ethanol solution mass ratio of 1:3000 and stir evenly. Finally, tetraethyl orthosilicate was added according to the volume ratio of tetraethyl orthosilicate: ethanol solution of 1:500, and the above solution was stirred at 20°C for 10 hours, washed with deionized water and alcohol, filtered and dried to obtain carbon nano Tube / silica powder.

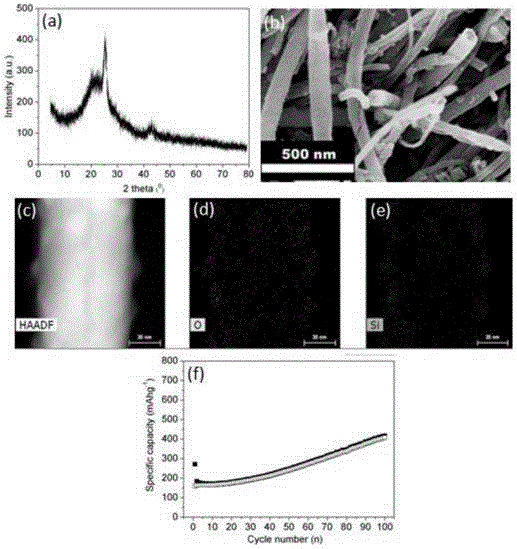

[0018] figure 1 (a) is the X-ray diffraction spectrum of carbon nanotubes / silicon dioxide. After calibration, it is fo...

Embodiment 2

[0020] According to absolute ethanol: the volume ratio of deionized water is 1:3 to configure ethanol solution, according to cetyltrimethylammonium bromide: the mass ratio of ethanol solution is 1:100 to cetyltrimethyl bromide Ammonium is dissolved in ethanol solution, and lithium hydroxide is added to the above solution while stirring, and the mass ratio of cetyltrimethylammonium bromide:lithium hydroxide is 10:1. After thorough stirring, add carbon nanotubes into the above solution according to the ratio of carbon nanotubes: ethanol solution mass ratio of 1:1000 and stir evenly. Finally, tetraethyl orthosilicate was added according to the volume ratio of tetraethyl orthosilicate: ethanol solution of 1:300, and the above solution was stirred at 40°C for 8 hours, washed with deionized water and alcohol, filtered and dried to obtain carbon nano Tube / silica powder. .

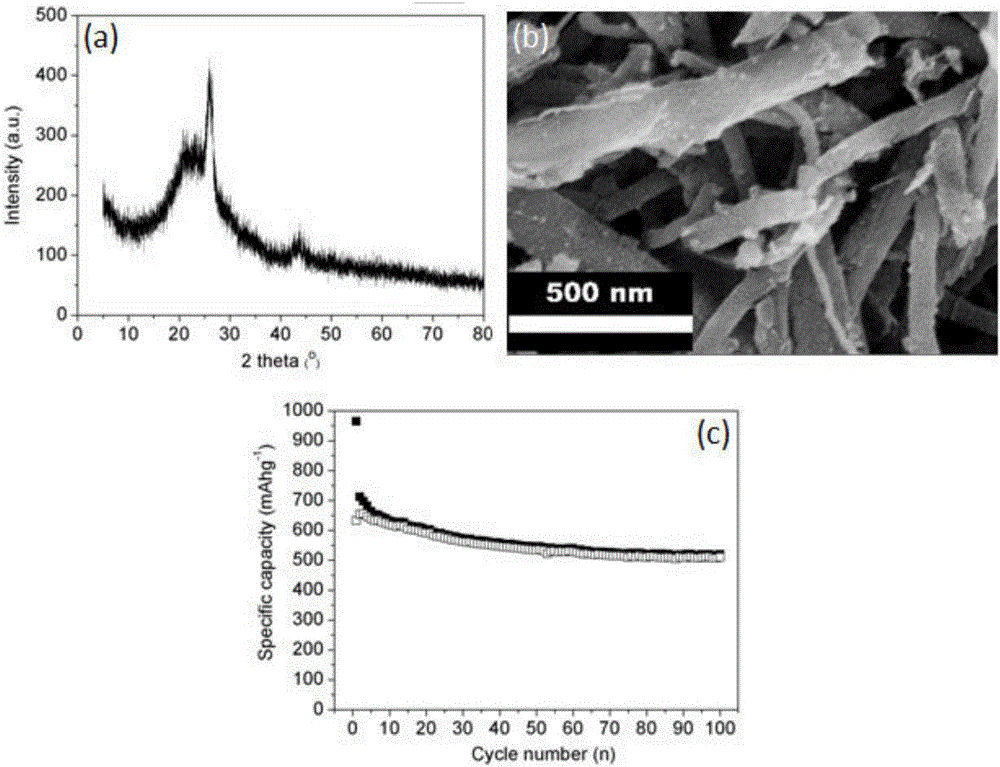

[0021] Mix the carbon nanotube / silicon dioxide powder and sucrose evenly in a mass ratio of 1:1, dissolve the...

Embodiment 3

[0024] According to absolute ethanol: the volume ratio of deionized water is 1:1 to configure ethanol solution, according to cetyltrimethylammonium bromide: the mass ratio of ethanol solution is 1:300 to cetyltrimethyl bromide Ammonium is dissolved in ethanol solution, and lithium hydroxide is added to the above solution while stirring, and the mass ratio of cetyltrimethylammonium bromide:lithium hydroxide is 20:1. After thorough stirring, add carbon nanotubes into the above solution according to the ratio of carbon nanotubes: ethanol solution mass ratio of 1:500 and stir evenly. Finally, tetraethyl orthosilicate was added according to the volume ratio of tetraethyl orthosilicate: ethanol solution of 1:100, and the above solution was stirred at 60°C for 5 hours, washed with deionized water and alcohol, filtered and dried to obtain carbon nano Tube / silica powder.

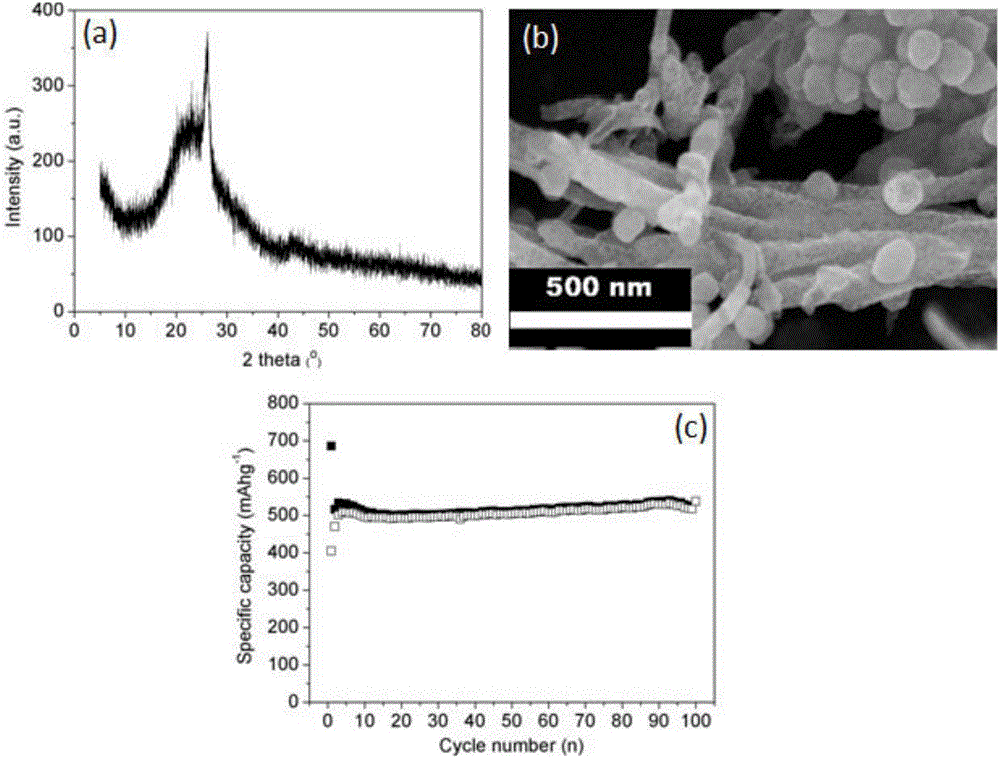

[0025] The carbon nanotube / silicon dioxide powder and sucrose were evenly mixed according to the mass ratio of 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com