Preparation method for graphene-coated titanium dioxide nanotube

A graphene-coated, titanium dioxide technology, applied in secondary batteries, electrochemical generators, electrical components, etc., can solve the problem of not having the advantages of tube structure, and achieve the advantages of charging and discharging cycle stability, improving rate performance, The effect of high battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

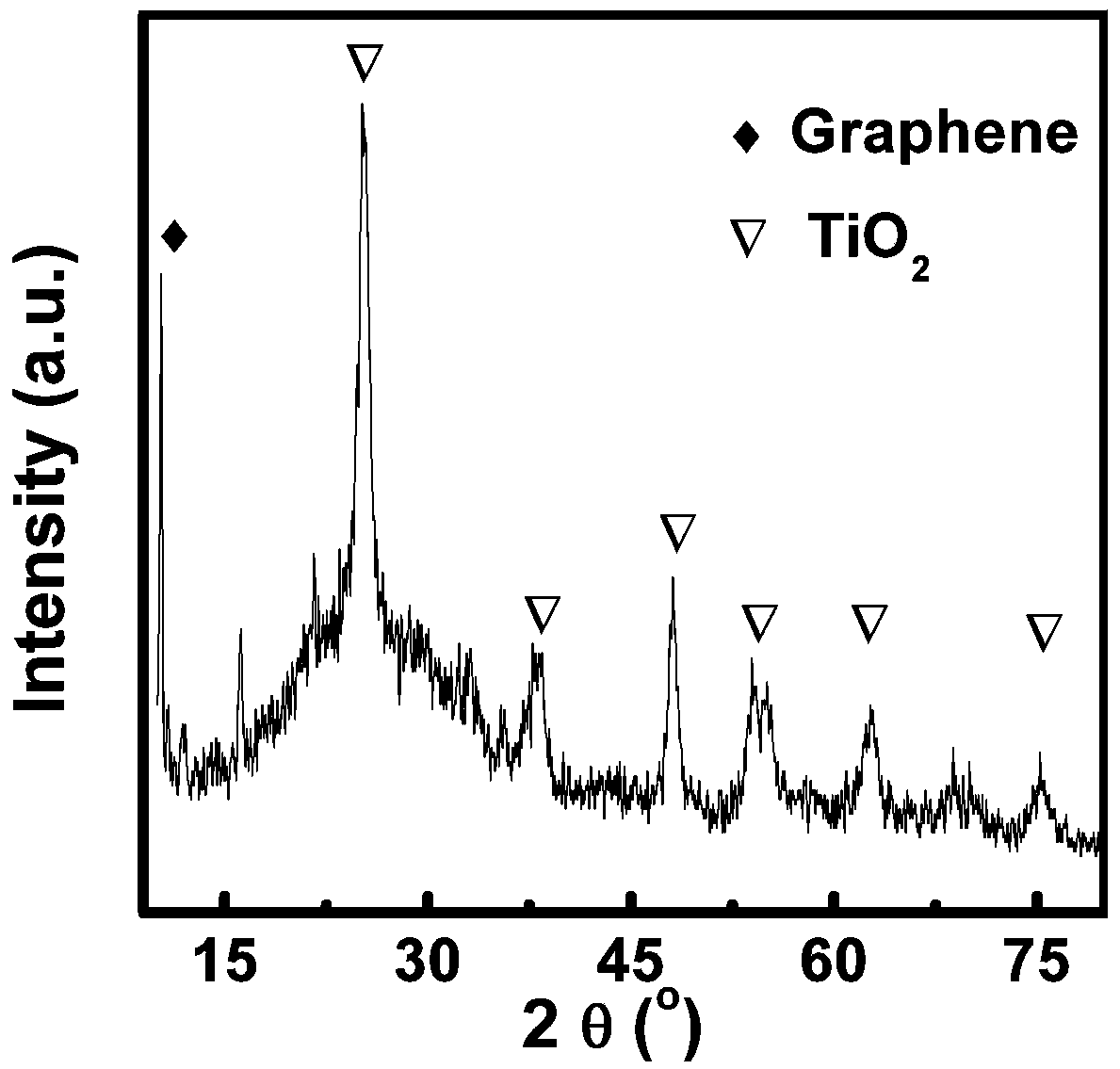

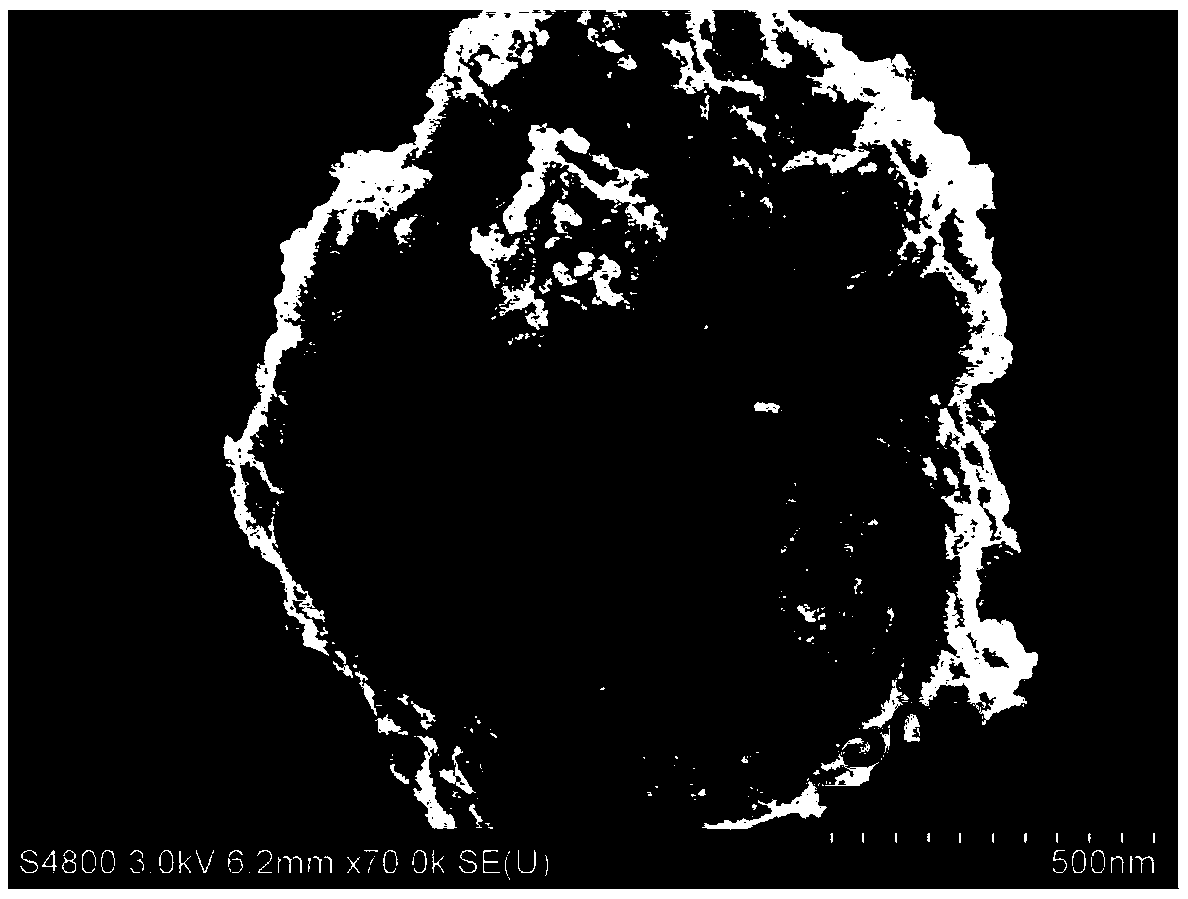

[0027] Referring to accompanying drawing, the present invention is the preparation method of the titanium dioxide nanotube of graphene coating, and its steps are:

[0028] S1. Take 0.1–5.0g of titanium dioxide nanoparticles and 10M sodium hydroxide into a hydrothermal kettle and stir for 2 hours to obtain a uniform dispersion; The product after the hydrothermal reaction is centrifuged, washed to neutrality, and then dried at low temperature to obtain titanium dioxide nanotubes;

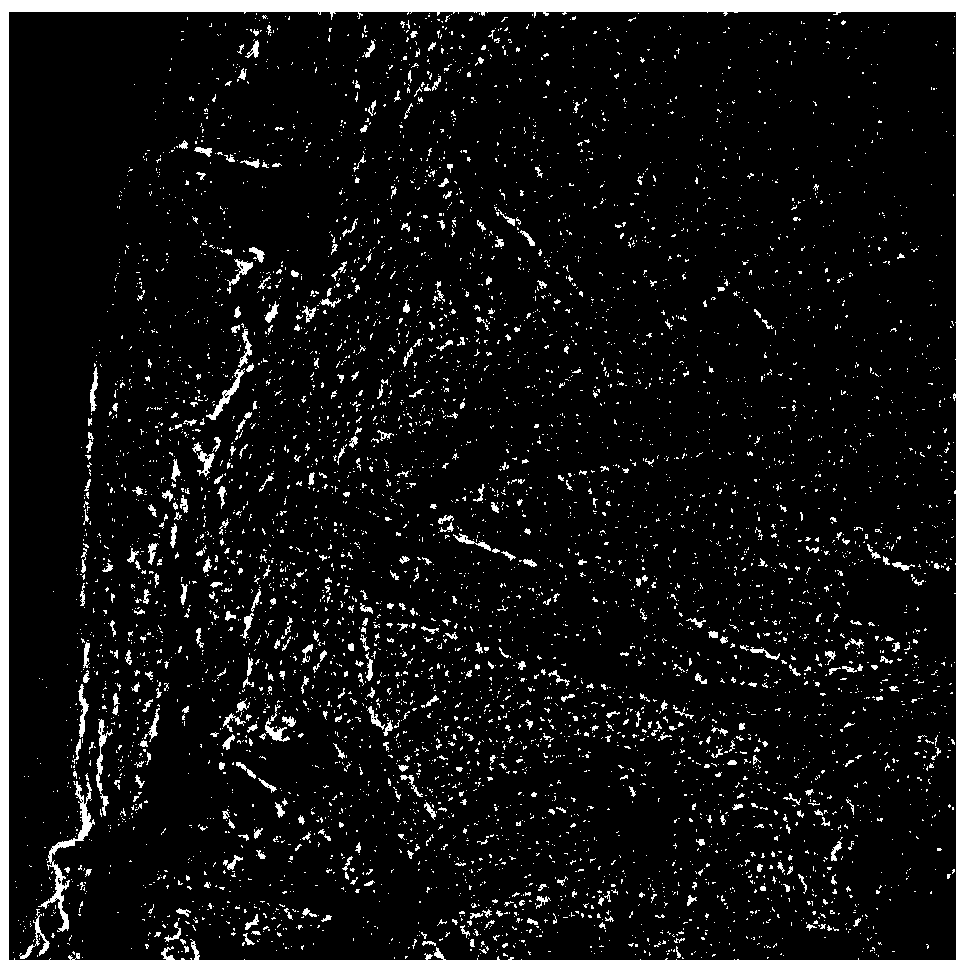

[0029] S2. Put 0.1–3.0g of titanium dioxide nanotubes and 1–10ml of APTMS into a 250ml beaker for reflux for 6 hours, filter the product in the beaker, and take the filtered filter residue for low-temperature drying to obtain amino-modified titanium dioxide tubes ;

[0030] S3, take 0.1-3.0g titanium dioxide tube with amino modification and 1ml concentration is 0.5mgml -1 The graphene oxide solution was fully stirred, and the filter residue was taken after filtration, and dried at low temperature to...

Embodiment 1

[0037] Embodiment 1 adopts this method to prepare graphene-coated titanium dioxide tube

[0038] S1. Hydrothermal preparation of titania nanotubes

[0039] 0.1 g of amorphous titanium dioxide nanoparticles and 10 M sodium hydroxide were put into a hydrothermal kettle and stirred for 2 hours to obtain a uniform dispersion. Then, at 130°C, the homogeneous dispersion was subjected to a hydrothermal reaction for 12 hours, and the product after the hydrothermal reaction was centrifuged and washed to neutrality (removing sodium hydroxide), and then dried at a temperature of 50°C for 16 hours. Titanium dioxide nanotubes are obtained.

[0040] S2. Coated amino

[0041] Get the titanium dioxide nanotube of 0.1g and the 3-(trimethoxysilyl)-1-propanamine (APTMS) of 2ml and put into reflux 6h in the 250ml beaker, the product in the beaker is filtered, get the filter residue after filtering at a temperature of Dry at 60°C for 14 hours to obtain an amino-modified titanium dioxide tube. ...

Embodiment 2

[0046] Example 2 Using this method to prepare graphene-coated titanium dioxide tubes

[0047] S1. Hydrothermal preparation of titania nanotubes

[0048] 0.5 g of anatase-phase titanium dioxide nanoparticles and 10 M sodium hydroxide were put into a hydrothermal kettle and stirred for 2 hours to obtain a uniform dispersion. Then, at 130°C, the homogeneous dispersion was subjected to a hydrothermal reaction for 12 hours, and the product after the hydrothermal reaction was centrifuged, washed with water until neutral (sodium hydroxide was removed), and then dried at a temperature of 70°C for 10 hours. Titanium dioxide nanotubes are obtained.

[0049] S2. Coated amino

[0050] Get the titanium dioxide nanotube of 0.3g and the 3-(trimethoxysilyl)-1-propanamine (APTMS) of 5ml and put into reflux 6h in the 250ml beaker, the product in the beaker is filtered, get the filter residue after filtering at a temperature of Dry at 70°C for 6 hours to obtain an amino-modified titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com