Nickel hydroxide/nickel disulfide/foam nickel composite and preparation method thereof, and application thereof

A technology of trinickel disulfide and nickel hydroxide, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of reduced overpotential and poor performance of catalytic electrolysis of water, and achieve excellent overall performance. Water-based electrolysis, simple preparation process, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

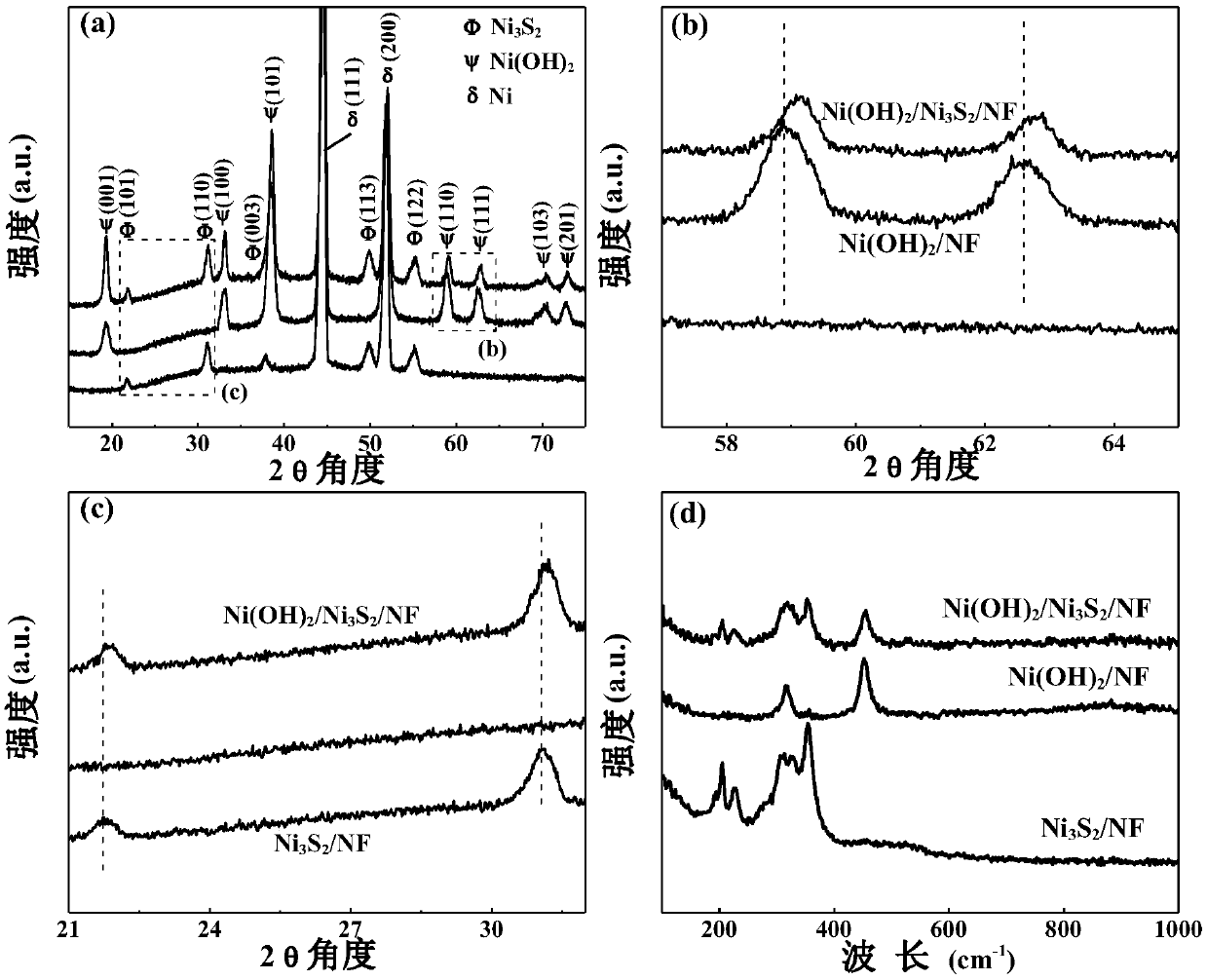

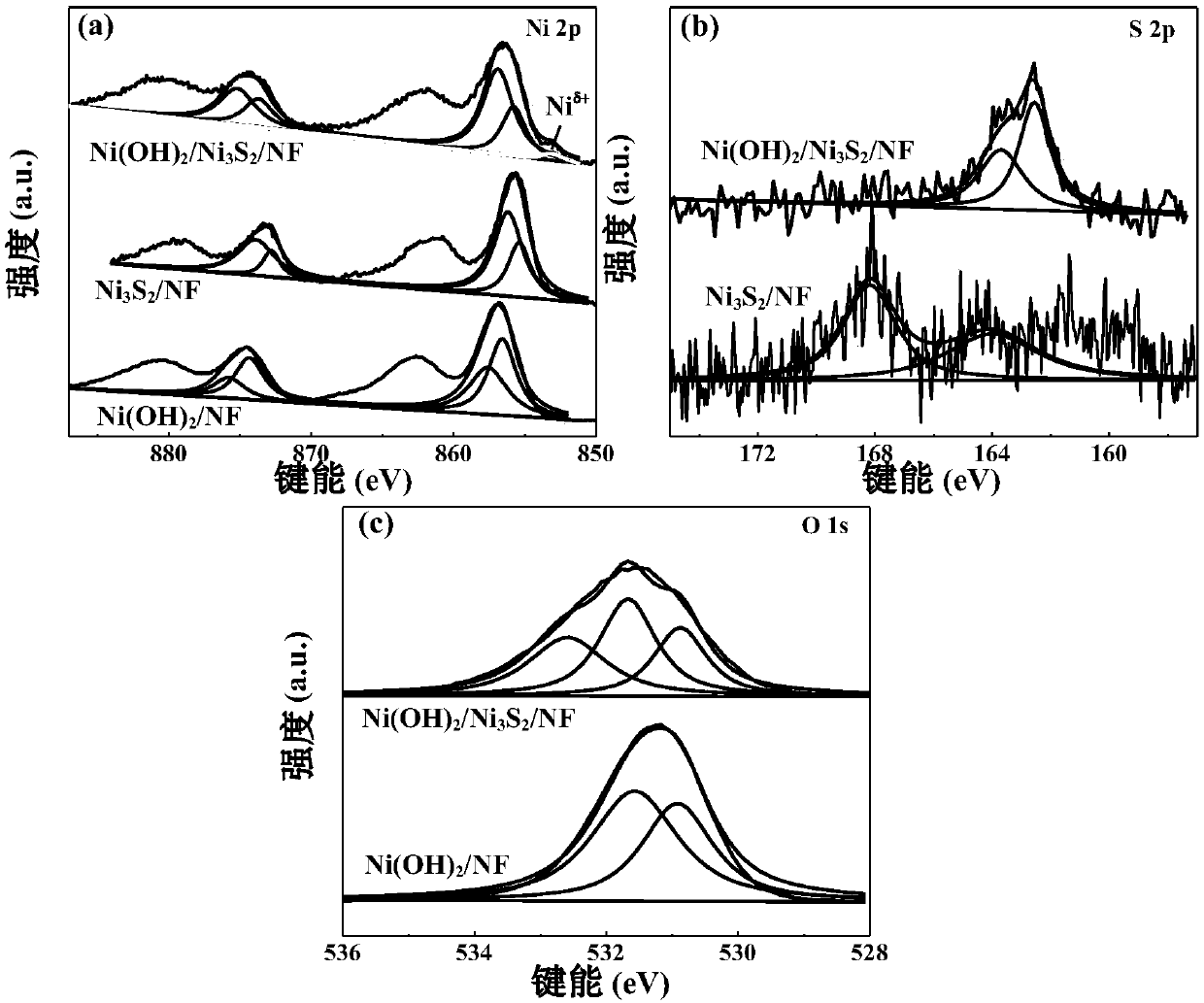

[0046] A preparation method of nickel hydroxide / nickel disulfide / foam nickel composite, comprising the following steps:

[0047] (1) Place nickel foam in a 1:1 mixed solution of ethanol and acetone for ultrasonic cleaning to remove surface oil, then place nickel foam in 5mol L -1 Dry at 100°C after being treated in dilute hydrochloric acid solution for 5 minutes;

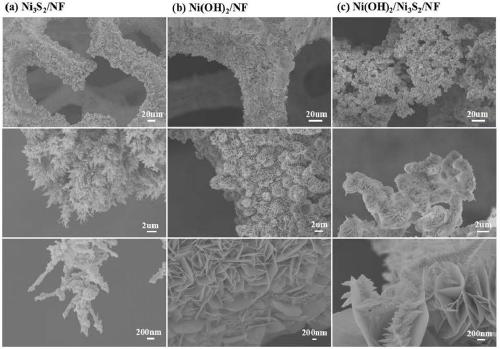

[0048] (2) Cut the dried nickel foam in step (1) into a size of 3cm×3cm, put it into a polytetrafluoroethylene-lined reactor with a capacity of 80mL, and dissolve 5mmol of thioacetamide in 50mL of aqueous solution solution 1; transfer solution 1 to the above reaction kettle, react at 160°C for 4 hours and then wash and dry to obtain nano-dry nickel disulfide that is longer than nickel foam. trunk-like Ni 3 S 2 / NF;

[0049] (3) the nickel nitrate hexahydrate of 1.5mmol is dissolved in the mixed solution of 10ml ethanol and 40mL water and then joins in the polytetrafluoroethylene liner, puts into the nano-trunk s...

Embodiment 2

[0051] A preparation method of nickel hydroxide / nickel disulfide / foam nickel composite, comprising the following steps:

[0052] (1) Place nickel foam in a 1:1 mixed solution of ethanol and acetone for ultrasonic cleaning to remove surface oil, then place nickel foam in 5mol L -1 Dry at 100°C after being treated in dilute hydrochloric acid solution for 5 minutes;

[0053] (2) Cut the dried nickel foam in step (1) into a size of 3cm×18cm, put it into a polytetrafluoroethylene-lined reactor with a capacity of 80mL, and dissolve 5mmol of thioacetamide in 50mL of aqueous solution solution 1; transfer solution 1 to the above reaction kettle, react at 160°C for 4 hours and then wash and dry to obtain nano-dry nickel disulfide that is longer than nickel foam. trunk-like Ni 3 S 2 / NF;

[0054] (3) the nickel nitrate hexahydrate of 1.5mmol is dissolved in the mixed solution of 10ml ethanol and 40mL water and then joins in the polytetrafluoroethylene liner, adds the Ni of the nano t...

Embodiment 3

[0056] A preparation method of nickel hydroxide / nickel disulfide / foam nickel composite, comprising the following steps:

[0057] (1) Place nickel foam in a 1:1 mixed solution of ethanol and acetone for ultrasonic cleaning to remove surface oil, then place nickel foam in 5mol L -1 Dry at 100°C after being treated in dilute hydrochloric acid solution for 5 minutes;

[0058] (2) Cut the dried nickel foam in step (1) into a size of 3cm×3cm, put it into a polytetrafluoroethylene-lined reactor with a capacity of 80mL, and dissolve 5mmol of thioacetamide in 50mL of aqueous solution solution 1; transfer solution 1 to the above reaction kettle, react at 160°C for 4 hours and then wash and dry to obtain nano-dry nickel disulfide that is longer than nickel foam. trunk-like Ni3 S 2 / NF;

[0059] (3) the nickel nitrate hexahydrate of 1.0mmol is dissolved in the mixed solution of 10ml ethanol and 40mL water and then joins in the polytetrafluoroethylene liner, adds the nano tree trunk sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com