Making method of nickel hydroxide with coated gamma hydroxy cobalt oxide

A technology of nickel hydroxide and γ-hydroxyl coating, which is applied in the direction of nickel oxide/nickel hydroxide, cobalt carbonyl, alkaline battery electrodes, etc., and can solve the problems that the preparation method has not seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

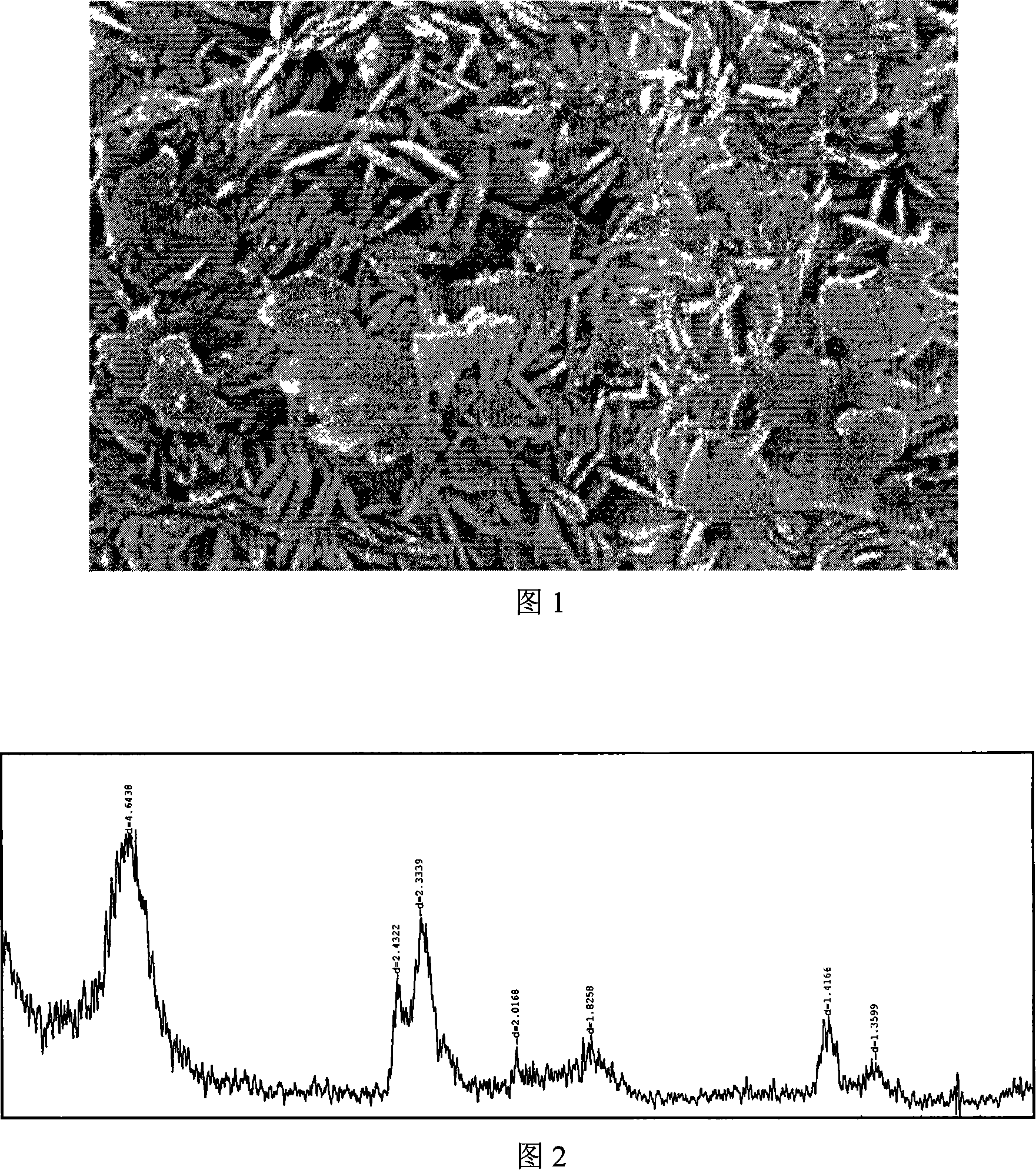

Image

Examples

Embodiment 1

[0029] Main raw material: spherical nickel hydroxide substrate is commercially available (produced by Jintian Energy Materials Co., Ltd.).

[0030] ① Solution preparation: 1M cobalt sulfate solution, 20% sodium hydroxide solution, 20% ammonia solution.

[0031] ② Coated cobalt hydroxide:

[0032]Put the main raw materials into the reactor, add pure water, sodium hydroxide solution and ammonia solution to form a reaction with a nickel hydroxide solid concentration of 200 g / L, an ammonia concentration of 5 g / L, a pH of 9.5, and a temperature of 60 °C. solution; then the prepared 1M cobalt sulfate solution, 20% sodium hydroxide solution, and 20% ammonia solution were simultaneously and continuously added to the reactor, and the temperature of the reaction system was kept at 60°C under the stirring condition of 200 rpm. The pH is 9.5, the ammonia concentration in the system is 5 g / L, and the reaction time lasts for 3 hours. The amount of cobalt solution added in the reaction is ...

Embodiment 2

[0036] The nickel hydroxide active material A with the surface coating gamma cobalt oxyhydroxide obtained in Example 1 is subjected to doping modification treatment, the method is:

[0037] The nickel hydroxide active material A of the surface coating gamma cobalt oxyhydroxide is added in the lithium hydroxide solution of 10 grams / liter, makes the solid concentration of nickel hydroxide active material A in the solution be 200 grams / liter, under stirring condition Maintain the temperature of the reaction system at 60°C, and the reaction time is 30min; then filter the treated material, wash it with pure water until the pH is 8.0, and then dry it at 110°C to obtain the surface-coated γ cobalt oxyhydroxide hydroxide Nickel active material B.

[0038] The powder impedance of the nickel hydroxide active material B obtained in Example 2 is 1 Ω cm, and the average valence state of cobalt coated with cobalt on the surface is 3.16 as measured by iodometric method; the M content in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com