Method for leaching nickel and cobalt form low-iron and high-magnesium and high-iron and low-magnesium laterite-nickel ore by using waste dilute sulphuric acid

A technology of laterite nickel ore and dilute sulfuric acid is applied in the field of high iron and low magnesium laterite nickel ore leaching nickel and cobalt with waste dilute sulfuric acid, low iron and high magnesium, and can solve the problems of increased investment risk, secondary pollution, high cost, etc. Reasonable technological advancement, safe operation, and reduced raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

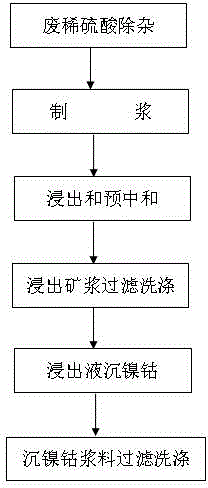

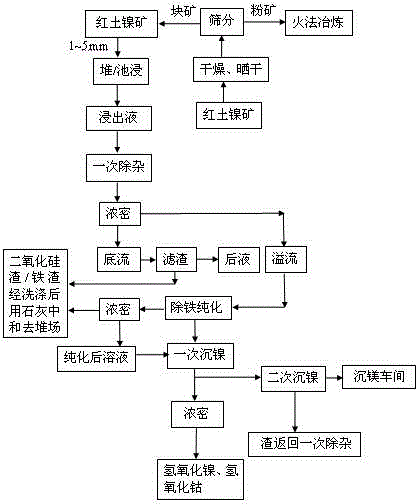

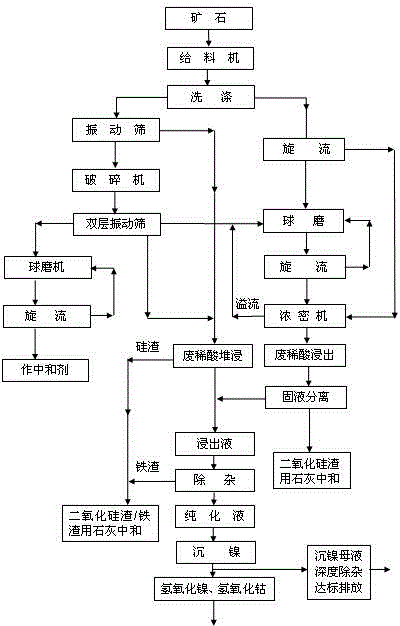

Method used

Image

Examples

Embodiment 1

[0045] The test ore sample is low-iron and high-magnesium laterite nickel ore, containing 2.26% nickel, 0.09% cobalt, 13.8% iron, and 26.5% magnesium oxide. The grinding particle size -0.075mm accounts for 90%, the pulp concentration is 42%, and the mass concentration is 23.5%. The mass ratio of dilute sulfuric acid to dry ore is 0.85:1, the liquid-solid ratio is 2.5:1, leaching for one hour, introducing air to pressurize the pressure in the kettle to 0.25MPa, continuing leaching for half an hour, adding 30% of the original ore content of high magnesium ore, continue leaching for 2.5 hours, add magnesite to neutralize to pH 5.7, leach ore slurry liquid-solid separation, leaching liquid magnesite to precipitate nickel. Results: The recovery rate of nickel was 97.6%, and the recovery rate of cobalt was 95.3%.

Embodiment 2

[0047] The test ore sample is a mixed ore sample. The upper layer of high-iron and low-magnesium laterite nickel ore contains 1.51% nickel, 0.10% cobalt, 25.3% iron, and 13.8% magnesium oxide, and the lower layer contains 1.8% nickel and 0.02% cobalt. Iron 15.4%, magnesium oxide 27.2%. The high-iron and low-magnesium laterite nickel ore is ground to a particle size of -0.075mm, accounting for 90%, and the pulp concentration is 45%. The low-iron, high-magnesium laterite nickel ore is ground to a particle size of -0.075mm, accounting for 85%, and the pulp concentration is 55%. According to the conditions of dilute sulfuric acid with a mass concentration of 25% and high iron and low magnesium laterite nickel ore at a mass ratio of 0.75:1 and a liquid-solid ratio of 2.5:1, leaching for one hour, adding low iron high Magnesium laterite nickel ore, add sulfuric acid with a mass concentration of 25% equivalent to 40% of low-iron high-magnesium laterite nickel ore at the same time, fe...

Embodiment 3

[0049] The test ore sample is a mixed ore sample. The upper layer of high-iron and low-magnesium laterite nickel ore contains 1.80% nickel, 0.20% cobalt, 36.23% iron, and 6.21% magnesium oxide. The lower layer contains 2.33% nickel and 0.05% cobalt. Iron 13.56%, magnesium oxide 21.37%. The high-iron and low-magnesium laterite nickel ore is ground to a particle size of -0.075mm, accounting for 85%, and the pulp concentration is 45%. The low-iron, high-magnesium laterite nickel ore is ground to a particle size of -0.075mm, accounting for 90%, and the pulp concentration is 55%. According to the conditions of dilute sulfuric acid with a mass concentration of 28% and the mass ratio of high-iron and low-magnesium laterite nickel ore of 0.9:1 and liquid-solid ratio of 2.5:1, leaching for one hour, adding low-iron and high-magnesium ore equivalent to 45% of high-iron and low-magnesium laterite nickel ore Laterite nickel ore, at the same time, add sulfuric acid with a mass concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com