Method for preparing graphene-nickel hydroxide composite electrode material for super capacitor

A technology of supercapacitors and nickel hydroxide, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of complex and cumbersome chemical synthesis paths, difficult to repeat preparation conditions, high-cost synthetic raw materials, etc., and achieve good cycle stability, Effect of short response time and high specific capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

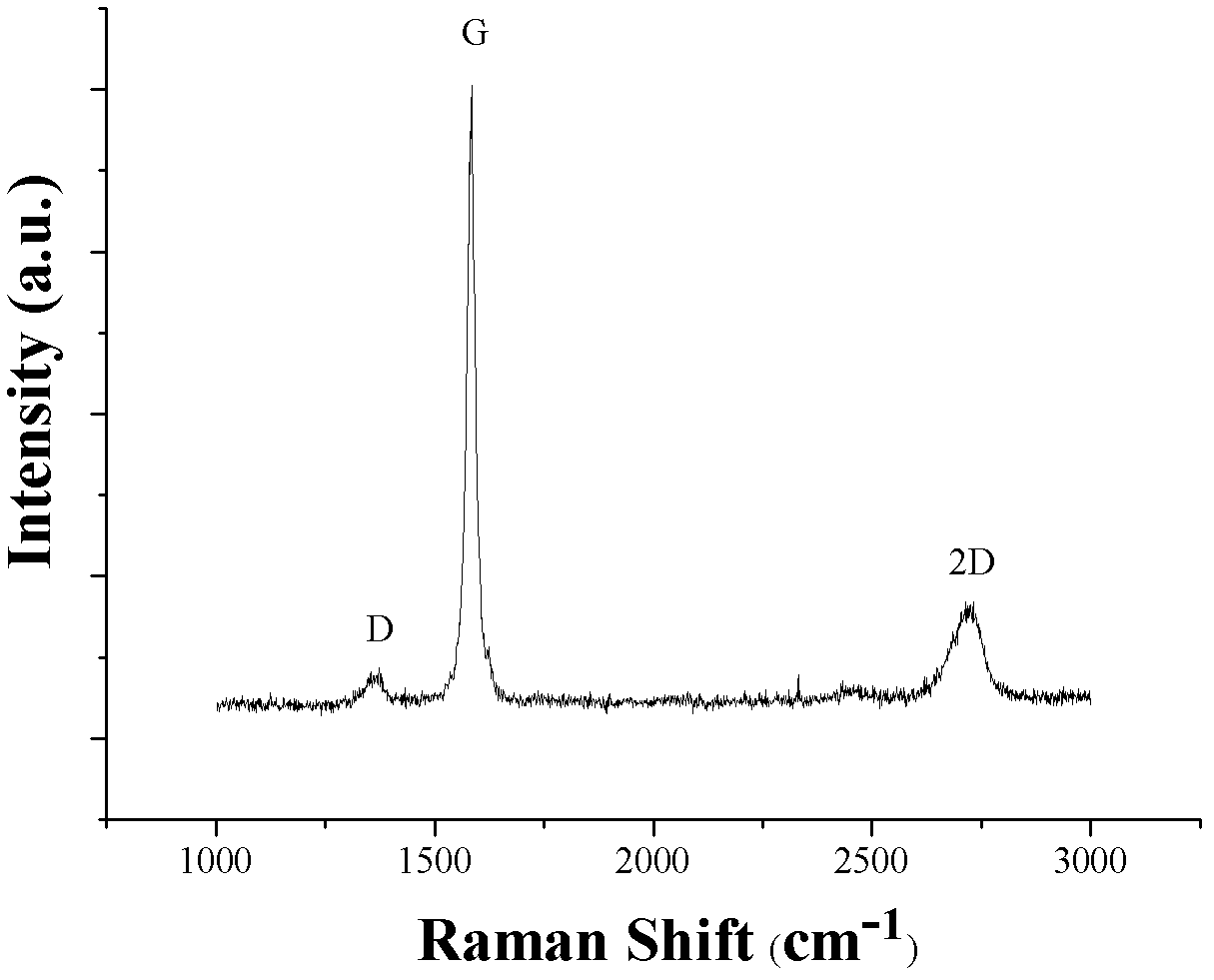

[0049] 1) Use nickel foam as the substrate, use PECVD equipment, heat up to 800°C in a hydrogen atmosphere, and the heating rate is 20°C / min. When this temperature is reached, methane gas is introduced to make the ratio of methane to hydrogen 1:8 , the total pressure is controlled at 4 Torr;

[0050] 2) In the PECVD equipment, after step 1) is completed, the RF power is turned on, the RF power is controlled at 200W, and the deposition time is 30min;

[0051] 3) After the reaction is over, continue to pass hydrogen to room temperature;

[0052] 4) With 0.1M Ni(NO 3 ) 2 As the electrolyte, the surface of the graphene-nickel foam substrate material prepared by the above method in contact with the plasma environment is used as the working electrode opposite to the platinum sheet, the platinum sheet is the counter electrode, and the saturated calomel electrode is the reference electrode. , to -1mA / cm 2 Constant current deposition of nickel hydroxide, the time is 12min.

[0053...

Embodiment 2

[0062] 1) Using nickel foam as the substrate, using PECVD equipment, the temperature is raised to 800°C in a hydrogen atmosphere, and the heating rate is 20°C / min. When this temperature is reached, methane gas is introduced so that the ratio of methane to hydrogen is 1:8 , the total pressure is controlled at 4Torr;

[0063] 2) In the PECVD equipment, after step 1) is completed, the RF power is turned on, the RF power is controlled at 200W, and the deposition time is 30min;

[0064] 3) After the reaction is over, continue to pass hydrogen to room temperature;

[0065] 4) With 0.1M Ni(NO 3 ) 2 For the electrolyte, the surface of the graphene-nickel foam substrate material prepared by the above method is in contact with the PECVD reaction chamber stage (that is, the side that is not in contact with the plasma environment) as the opposite working surface of the platinum sheet. Electrode, platinum sheet as counter electrode, saturated calomel electrode as reference electrode, wi...

Embodiment 3

[0068] 1) Use nickel foam as the substrate, use PECVD equipment, heat up to 800°C in a hydrogen atmosphere, and the heating rate is 20°C / min. When this temperature is reached, methane gas is introduced to make the ratio of methane to hydrogen 1:8 , the total pressure is controlled at 4 Torr;

[0069] 2) In the PECVD equipment, after step 1) is completed, the RF power is turned on, the RF power is controlled at 200W, and the deposition time is 30min;

[0070] 3) After the reaction is over, continue to pass hydrogen to room temperature;

[0071] 4) With 0.1M Ni(NO 3 ) 2 As the electrolyte, the graphene-nickel foam substrate material prepared by the above method is used as the working electrode, the platinum sheet is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. 2 Constant current deposition of nickel hydroxide, the time is 3min.

[0072] According to the exemplifying method of the above-mentioned invention, the in-situ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com