A polyaniline-porous carbon composite electrode material with interfacial covalent bonds and its preparation method

A composite electrode and porous carbon technology, applied in the field of materials, can solve the problem of inappropriate porous carbon, and achieve the effects of low price, excellent cycle stability, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a polyaniline-porous carbon composite material with interfacial covalent bonds, comprising the following steps:

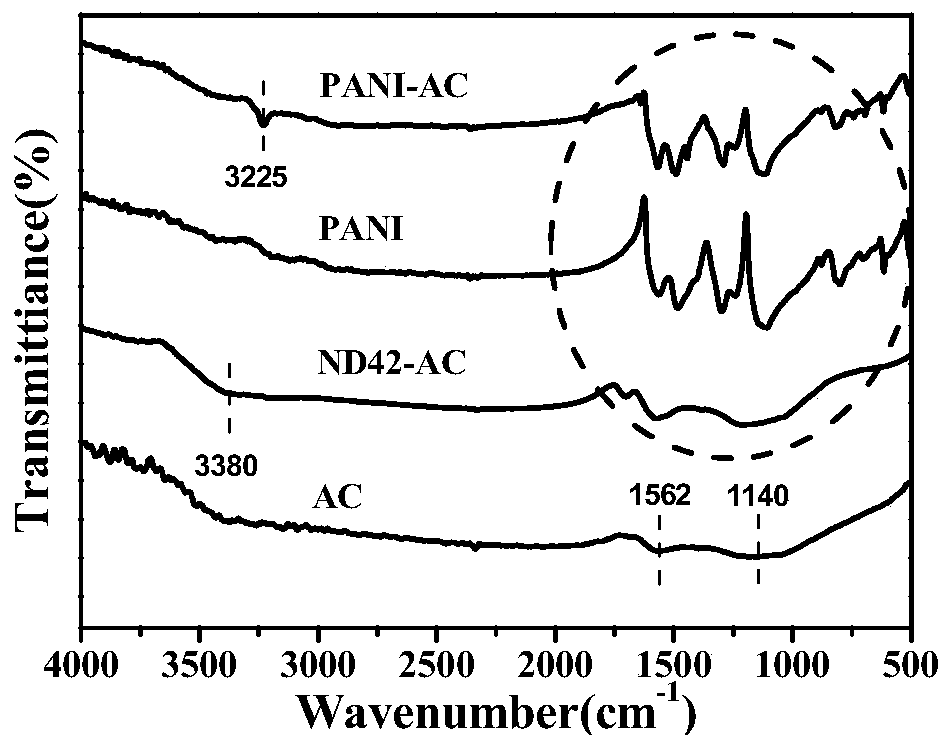

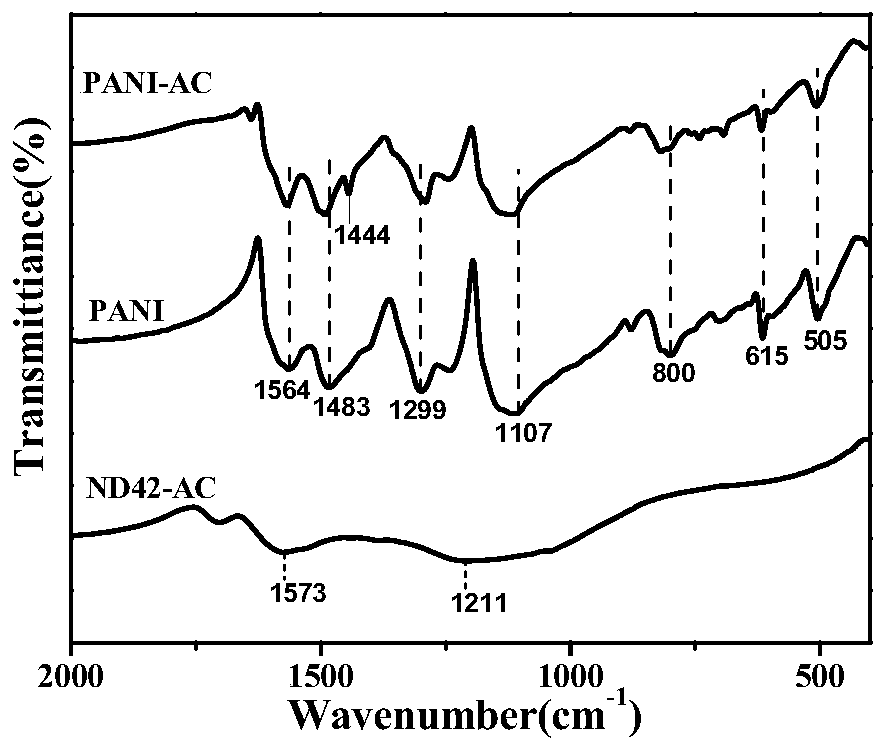

[0040] (1) Take nitric acid and be mixed with 100 mL of nitric acid aqueous solution with a mass concentration of 16%, mix the prepared nitric acid aqueous solution and 10 grams of commercial activated carbon (abbreviated as AC) into a three-necked flask, and reflux for 5 hours under constant temperature magnetic stirring in a water bath at 50 ° C. . After the reaction is complete, filter while it is hot, and wash with distilled water until it is neutral. The filtrate is dried in an oven at 110°C for 12 hours. After cooling, black powdery nitric acid activated porous carbon is obtained. Take it out for use, and record it as HNO 3 -AC.

[0041] (2) Take 5 grams of the above-mentioned HNO 3 -AC is dispersed in a mixture of 100mL toluene and 5mL silane coupling agent anilinomethyltriethoxysilane (hereinafter referred to as ND42), 200W ult...

Embodiment 2

[0061] (1) Take nitric acid and be mixed with 100 mL of nitric acid aqueous solution with a mass concentration of 18%, mix the prepared nitric acid aqueous solution and 10 grams of commercial activated carbon (abbreviated as AC) into a three-necked flask, and reflux for 5 hours under constant temperature magnetic stirring in a water bath at 50 ° C. . After the reaction is complete, filter while it is hot, and wash with distilled water until it is neutral. The filtrate is dried in an oven at 110°C for 12 hours. After cooling, black powdery nitric acid activated porous carbon is obtained. Take it out for use, and record it as HNO 3 -AC.

[0062] (2) Take 4 grams of the above-mentioned HNO 3 -AC is dispersed in a mixture of 100mL toluene and 5mL silane coupling agent anilinomethyltriethoxysilane (hereinafter referred to as ND42), 200W ultrasonic dispersion for 1h; then heated to 110°C for reflux reaction for 24h; After cooling, filter with suction, wash with toluene, acetone, a...

Embodiment 3

[0067] (1) Take nitric acid and be mixed with 100 mL of nitric acid aqueous solution with a mass concentration of 16%, mix the prepared nitric acid aqueous solution and 10 grams of commercial activated carbon (abbreviated as AC) into a three-necked flask, and reflux for 5 hours under constant temperature magnetic stirring in a water bath at 50 ° C. . After the reaction is complete, filter while it is hot, and wash with distilled water until it is neutral. The filtrate is dried in an oven at 110°C for 12 hours. After cooling, black powdery nitric acid activated porous carbon is obtained. Take it out for use, and record it as HNO 3 -AC.

[0068] (2) Take 4 grams of the above-mentioned HNO 3 -AC is dispersed in a mixture of 100mL toluene and 4mL silane coupling agent anilinomethyltriethoxysilane (hereinafter referred to as ND42), 200W ultrasonic dispersion for 1h; then heated to 110°C for reflux reaction for 24h; After cooling, filter with suction, wash with toluene, acetone, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com