MnO2-RuO2 composite material, preparation method and application thereof

A composite material, the technology of ruthenium dioxide, applied in the directions of manganese oxide/manganese hydroxide, chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc., can solve the complex preparation process, poor conductivity, problems such as poor stability, to achieve the effects of good dispersion, high specific capacity, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

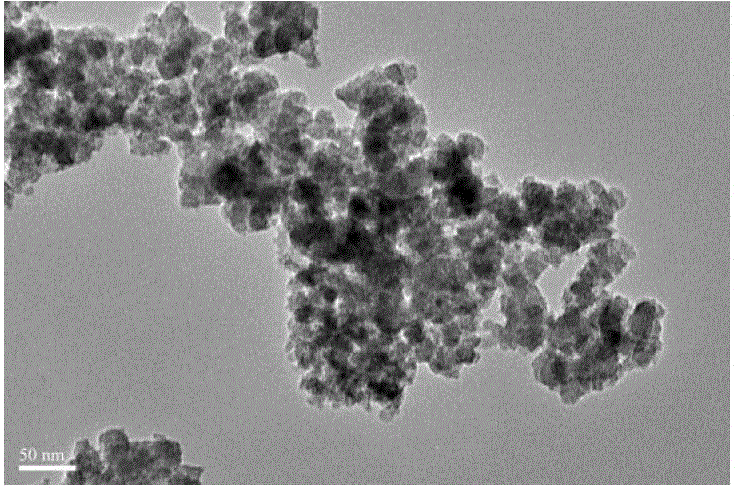

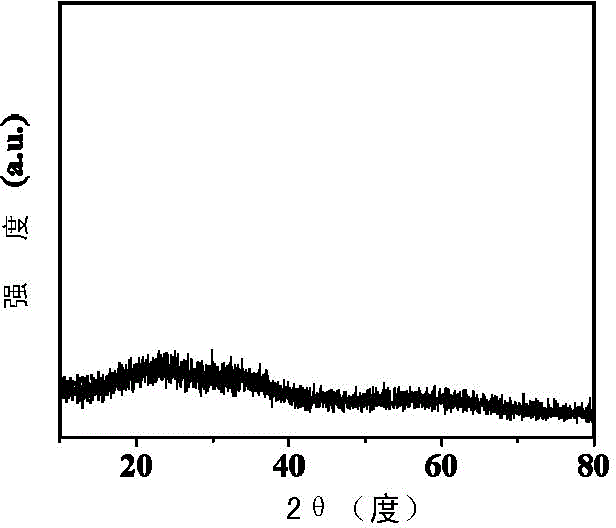

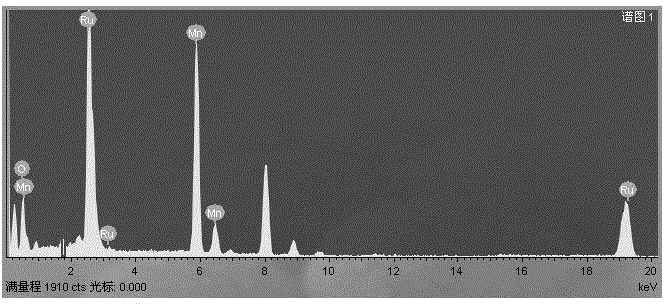

[0050] Prepare 0.1mol / L manganese chloride (MnCl 2 ) and ruthenium chloride (RuCl 3 ) aqueous solution of 200ml each; take 20ml of manganese chloride and ruthenium chloride aqueous solution, mix and stir for 5 minutes; add dropwise to the above solution until the pH value is 9; centrifuge filter, wash 3 times with water; dry at 80°C to obtain Ruthenium dioxide composite powder. The specific surface area of the composite was determined by nitrogen adsorption-desorption to be 135m 2 / g.

[0051] Oxygenate Ruthenium dioxide composite material powder and polyvinylidene fluoride (PVDF) N-methylpyrrolidone (NMP) solution (PVDF concentration: 25mg / ml) were evenly mixed to obtain a viscous slurry, which was coated on graphite paper as a working electrode; During chemical testing, platinum wire is used as the counter electrode, silver / silver chloride is used as the reference electrode, and 1mol / L Na 2 SO 4 The aqueous solution is electrolyte; the test instrument is Shanghai C...

Embodiment 2

[0061] Prepare 1mol / L respectively, 0.8mol / L, each 200ml of 0.4mol / L manganese chloride, prepare 20ml of 0.1mol / L ruthenium chloride aqueous solution; An amorphous manganese oxide-ruthenium dioxide composite material.

[0062] The above-mentioned amorphous manganese oxide-ruthenium dioxide composite materials with ratios of manganese and ruthenium of 4:1, 8:1, and 10:1 have the highest specific capacitances of 289F / g and 263F / g respectively at a scan rate of 2mV / s. , 224F / g.

[0063] Example 2 is to adjust the concentration of manganese chloride so that the molar ratio of ruthenium chloride and manganese chloride is changed within the range of 1: (4-10). The measured specific capacitance is lower than the 1:1 molar ratio of CO2 - specific capacitance value of ruthenium dioxide. This is due to the poor conductivity of manganese oxide, increasing the amount of manganese oxide leads to the weakening of charge transport, which reduces the specific capacitance of the composite ...

Embodiment 3

[0065] Using filter paper as a diaphragm and 1mol / L NaSO4 as an electrolyte, two electrode sheets obtained in Example 1 were placed on the front and back sides of the diaphragm to obtain a symmetrical supercapacitor (symmetrical cell). Active material area 1×1cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com