Method for keeping balance of sodium-magnesium-water system in technique for extracting nickel from lateritic nickel ore by wet process

A technology of laterite nickel ore and wet method, which is applied in the field of magnesium and water system balance and sodium retention in the process of wet nickel extraction from laterite nickel ore, which can solve the problems of large nickel loss, high energy consumption, and long process time, and achieve reduction Disposal cost, improvement of recovery rate, remarkable effect of economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

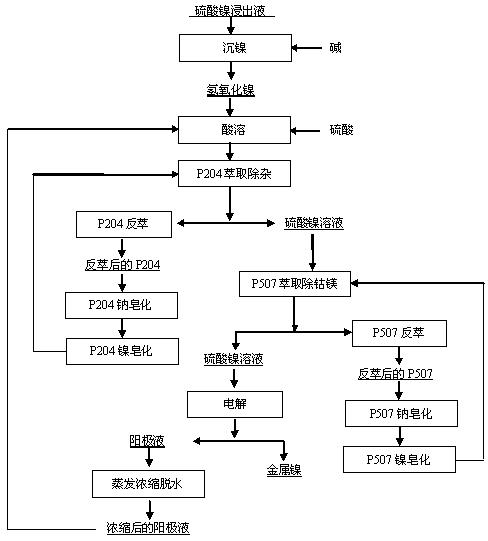

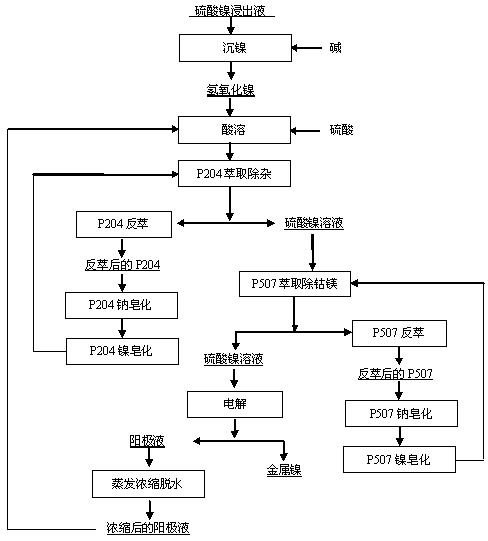

Image

Examples

Embodiment 1

[0029] See the process flow figure 1 , a lateritic nickel ore in the transitional layer produced in Indonesia, containing Ni 1.5%, Fe 20%, Mg 12.5%, after atmospheric sulfuric acid leaching, jarosite impurity removal, and solid-liquid separation, the nickel sulfate solution contains Ni 3.6g / L, Fe 0.18g / L, Mg 24g / L, this nickel sulfate solution is deposited nickel with the sodium hydroxide solution of 30%wt, and the nickel hydroxide obtained is acid-dissolved with concentrated sulfuric acid, and the prepared nickel sulfate solution Containing Ni 70g / L, Fe 0.01g / L, Na 32g / L, Mg 7.5g / L, it is extracted with P204 solvent to remove impurities such as iron, manganese, copper and zinc. The regeneration treatment steps of P204 before extraction and removal of impurities are as follows: Stir and mix the P204 organic phase after back-extraction with 500g / L sodium hydroxide solution, carry out saponification of P204 sodium, and measure the saponification rate of P204 in the organic phase...

Embodiment 2

[0031]The treatment process flow is the same as in Example 1. Laterite nickel ore contains 1.81% Ni, 22% Fe, and 15.5% Mg. After leaching with sulfuric acid at atmospheric pressure, impurity removal by jarosite method, and solid-liquid separation, the nickel sulfate solution contains Ni 4.3g / L, Fe 0.21g / L, Mg 26g / L, this nickel sulfate solution is deposited nickel with saturated calcium hydroxide solution, the nickel hydroxide obtained is acid-dissolved with concentrated sulfuric acid, and the obtained nickel sulfate solution contains Ni 72g / L, Fe 0.02g / L, Na 35g / L, Mg 8.5g / L, and P204 solvent extraction to remove impurities such as iron, manganese, copper and zinc. The regeneration treatment steps of P204 before extraction and removal of impurities are as follows: Stir and mix the P204 organic phase after back-extraction with 450g / L sodium hydroxide solution, carry out sodium saponification of P204, and measure the saponification rate of P204 in the organic phase by acid-base ...

Embodiment 3

[0033] The treatment process is the same as that in Example 1. Laterite nickel ore contains 1.40% Ni, 17.5% Fe, and 10.5% Mg. After being leached with sulfuric acid at atmospheric pressure, impurity removal by jarosite method, and solid-liquid separation, the nickel sulfate solution contains Ni 3.2g / L, Fe 0.15g / L, Mg 22g / L, this nickel sulfate solution is deposited nickel with 80g / L magnesium hydroxide solution, the nickel hydroxide obtained is acid-dissolved with concentrated sulfuric acid, and the obtained nickel sulfate The solution contains Ni 72g / L, Fe 0.02g / L, Na 35g / L, and Mg 15g / L. First, it is extracted with P204 solvent to remove impurities such as iron, manganese, copper, and zinc. The regeneration treatment steps of P204 before extraction and removal of impurities are as follows: Stir and mix the P204 organic phase after back-extraction with 500g / L sodium hydroxide solution, carry out saponification of P204 sodium, and measure the saponification rate of P204 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com