Nickel disulfide carbon nano composite material and preparation method and application thereof

A nanocomposite material, nickel disulfide carbon technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the conductivity of transition metal sulfides is not particularly good, affecting electrochemical performance, Structural collapse and other problems, to achieve the effect of excellent hydrophilicity, inhibition of structural collapse and fragmentation, reunion, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

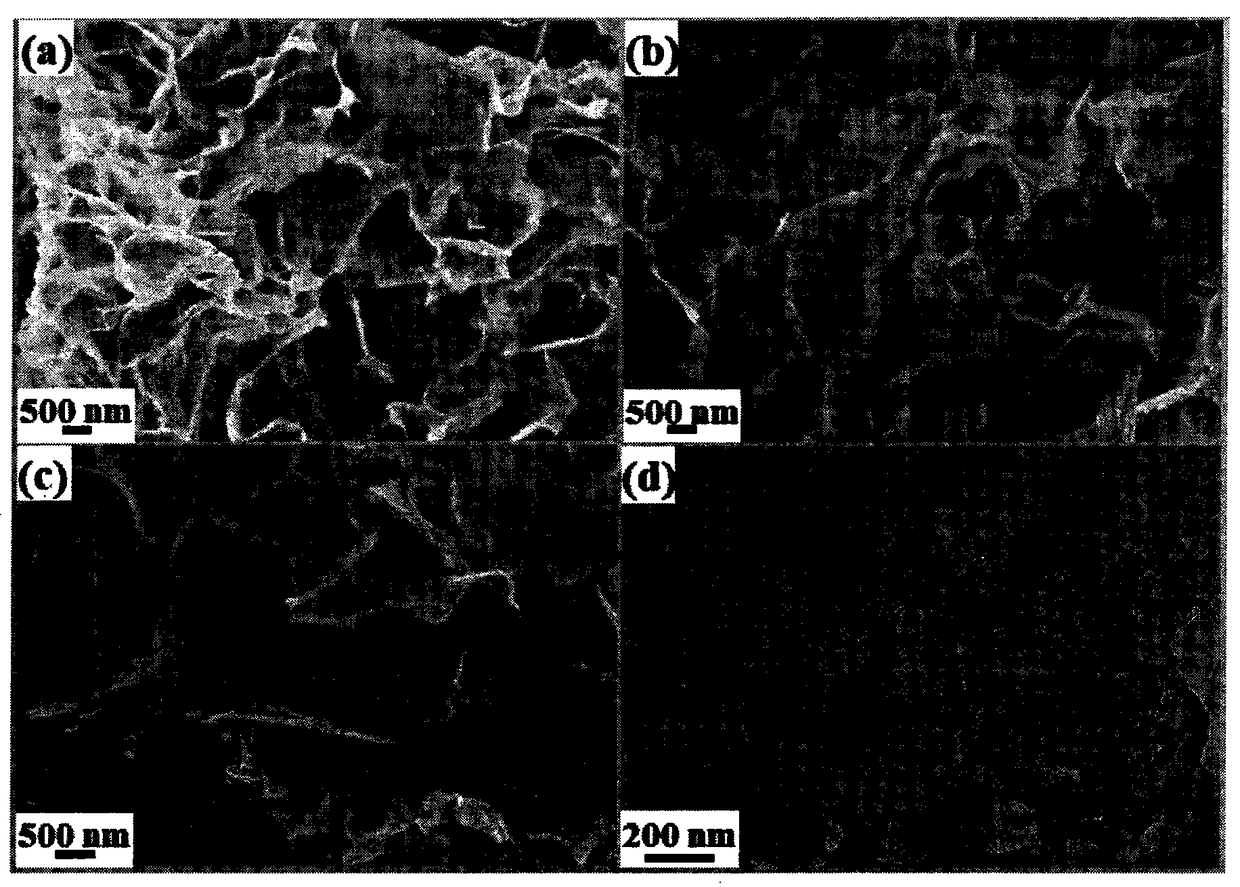

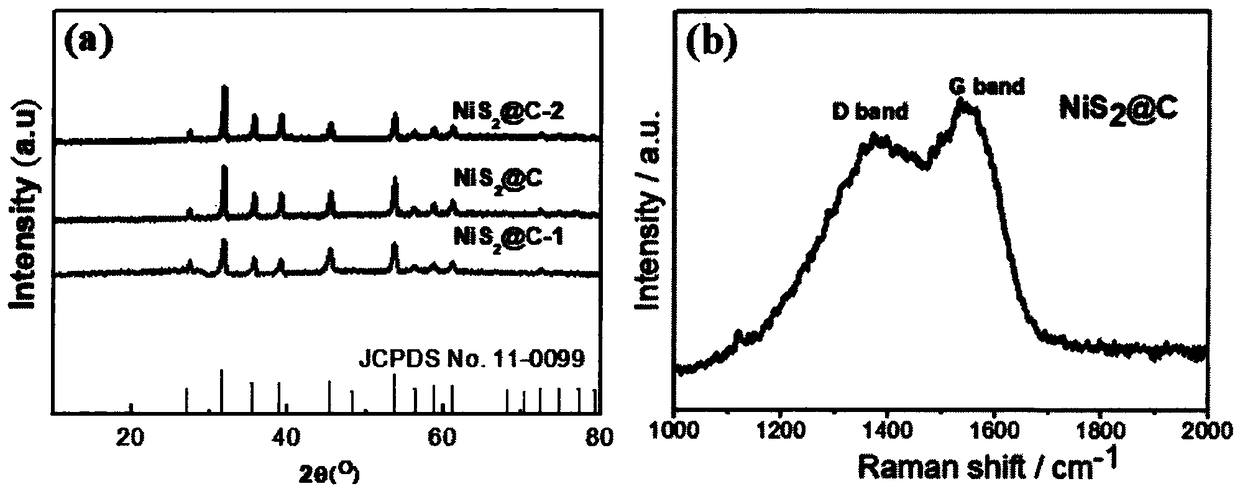

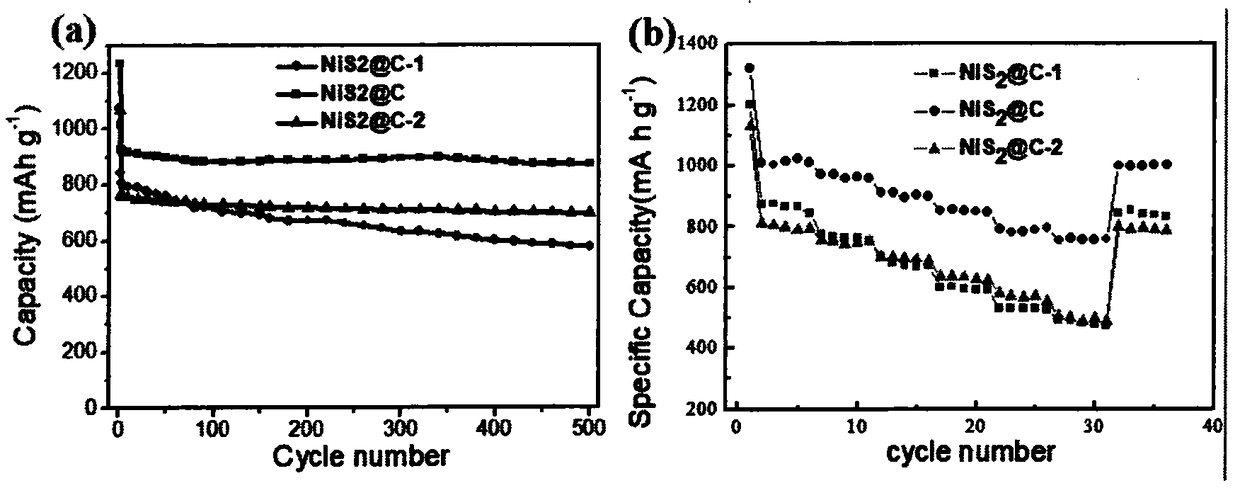

[0032] A nickel disulfide carbon nanocomposite material includes nickel disulfide nanosheets, and the nickel disulfide nanosheets are covered with a carbon layer. The overall structure of the nickel disulfide carbon nanocomposite material is in the shape of a uniform nanosheet, and the carbon layer is completely coated on the surface of the nickel disulfide nanosheet.

[0033] The preparation method of described nickel disulfide carbon nanocomposite material is:

[0034] (1) Preparation of nickel hydroxide nanosheet precursor by hydrothermal method. The specific implementation method includes: weighing 1.16g nickel nitrate hexahydrate, 0.48g hexamethylenetetramine, uniformly dissolving in 100mL deionized water, and placing in an oven at 110°C After reacting for 24 hours, the precipitated product was repeatedly washed with deionized water for several times, and dried in a vacuum oven at 60° C. to obtain a nickel hydroxide nanosheet precursor for future use.

[0035] (2) Take 2...

Embodiment 2

[0048] A nickel disulfide carbon nanocomposite material includes nickel disulfide nanosheets, and the nickel disulfide nanosheets are covered with a carbon layer. The overall structure of the nickel disulfide carbon nanocomposite material is in the shape of a uniform nanosheet, and the carbon layer is completely coated on the surface of the nickel disulfide nanosheet.

[0049] The preparation method of described nickel disulfide carbon nanocomposite material is:

[0050] (1) Preparation of nickel hydroxide nanosheet precursor by hydrothermal method. The specific implementation method includes: weighing 1.16g nickel nitrate hexahydrate, 0.48g hexamethylenetetramine, uniformly dissolving in 100mL deionized water, and placing in an oven at 110°C The reaction was carried out for 24 hours, and the product precipitate was repeatedly washed with deionized water for several times, and dried in a vacuum oven at 60°C to obtain the nickel hydroxide nanosheet precursor, which was set asid...

Embodiment 3

[0056] A nickel disulfide carbon nanocomposite material includes nickel disulfide nanosheets, and the nickel disulfide nanosheets are covered with a carbon layer. The overall structure of the nickel disulfide carbon nanocomposite material is in the shape of a uniform nanosheet, and the carbon layer is completely coated on the surface of the nickel disulfide nanosheet.

[0057] The preparation method of described nickel disulfide carbon nanocomposite material is:

[0058] (1) Preparation of nickel hydroxide nanosheet precursor by hydrothermal method. The specific implementation method includes: weighing 1.16g nickel nitrate hexahydrate, 0.48g hexamethylenetetramine, uniformly dissolving in 100mL deionized water, and placing in an oven at 110°C The reaction was carried out for 24 hours, and the product precipitate was repeatedly washed with deionized water for several times, and dried in a vacuum oven at 60°C to obtain the nickel hydroxide nanosheet precursor, which was set asid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com