Preparation method of lithium-ion battery positive electrode material spherical nickel-cobalt-lithium aluminate

A nickel-cobalt lithium aluminate and lithium-ion battery technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problem of uneven distribution of particle elements, achieve good cycle stability, high tap density, and ensure spherification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

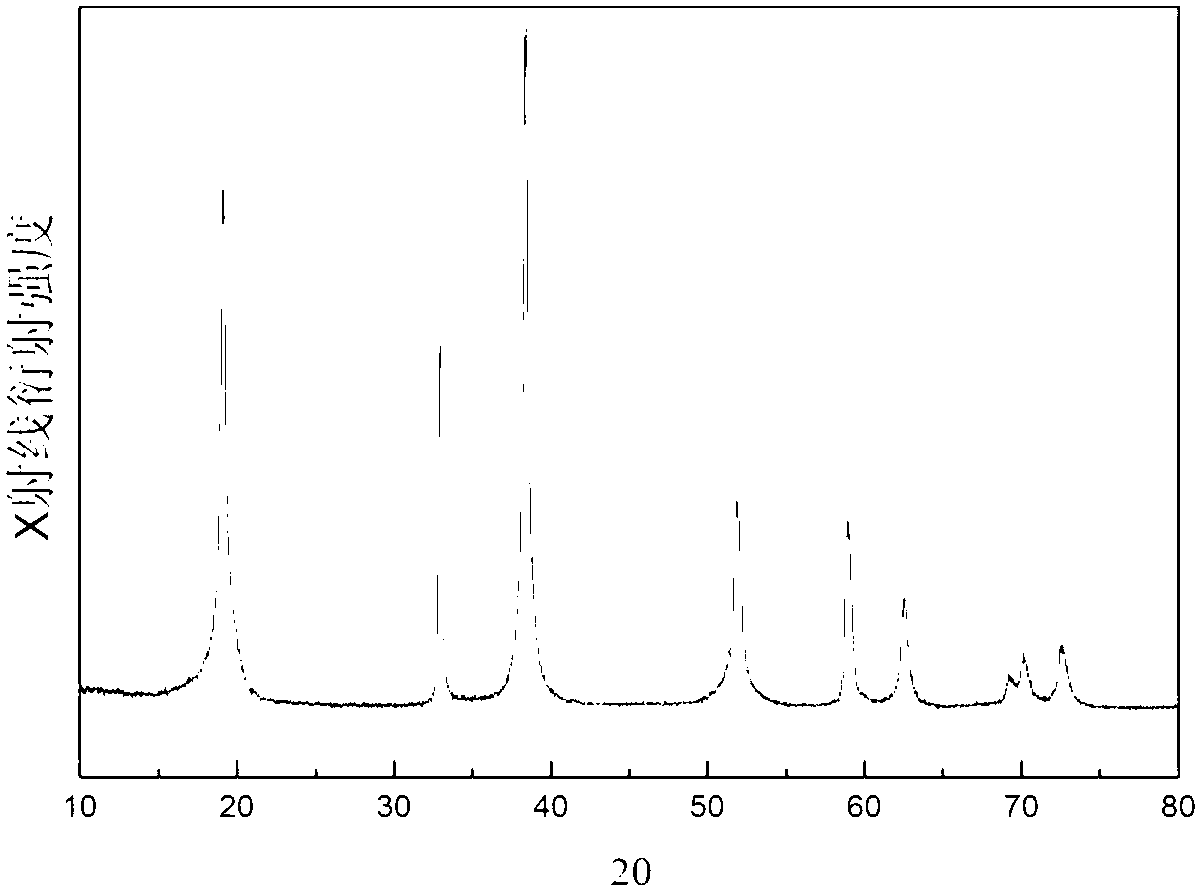

Embodiment 1

[0032] (1) Preparation of aluminum sol: 20.4g (ie 0.1mol) aluminum isopropoxide (C 9 h 21 AlO 3 ) and deionized water to make an aqueous solution containing 10wt% aluminum isopropoxide, put it in a three-necked flask, and stir continuously for 4 hours in a water bath at 85°C. After the aluminum isopropoxide is fully hydrolyzed, slowly drop 1mol / L HNO 3 Solution, the pH value is controlled at about 3, the hydrolyzate is slowly peptized, and the stirring is continued to make it age for 20 hours, and an egg white-colored boehmite AlOOH sol with certain fluidity and clarity is obtained.

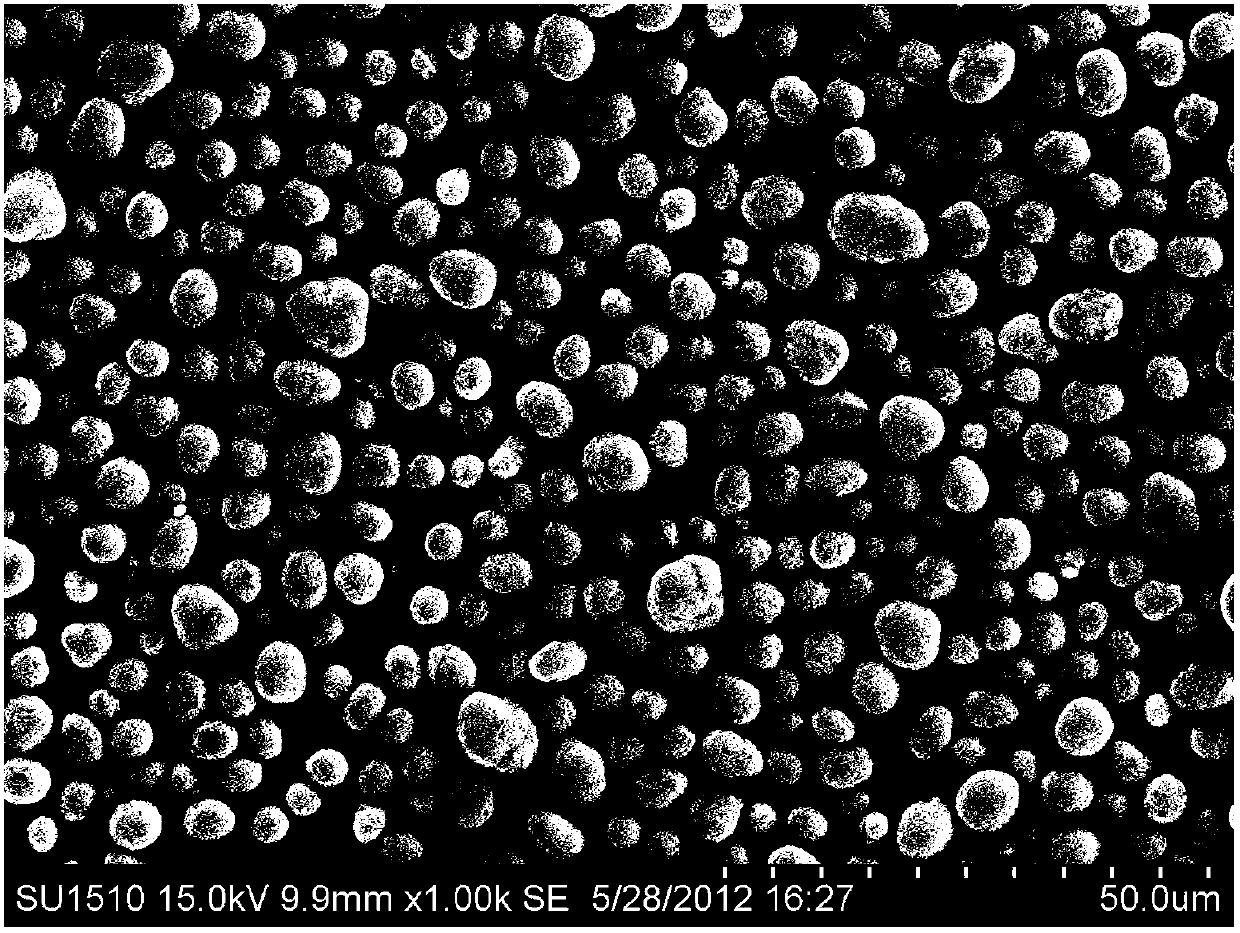

[0033](2) Preparation of nickel cobalt aluminum hydroxide precursor: mix nickel sulfate and cobalt sulfate according to n(Ni) / n(Co)=0.842:0.158, prepare 1L of 1mol / L aqueous solution, mix sodium hydroxide, ammonia water Make 1L of mixed alkali solution with concentrations of 2mol / L and 1mol / L respectively, then add mixed salt solution, aluminum sol (n(Ni+Co):n(Al)=0.95:0.05) and mixed alkali ...

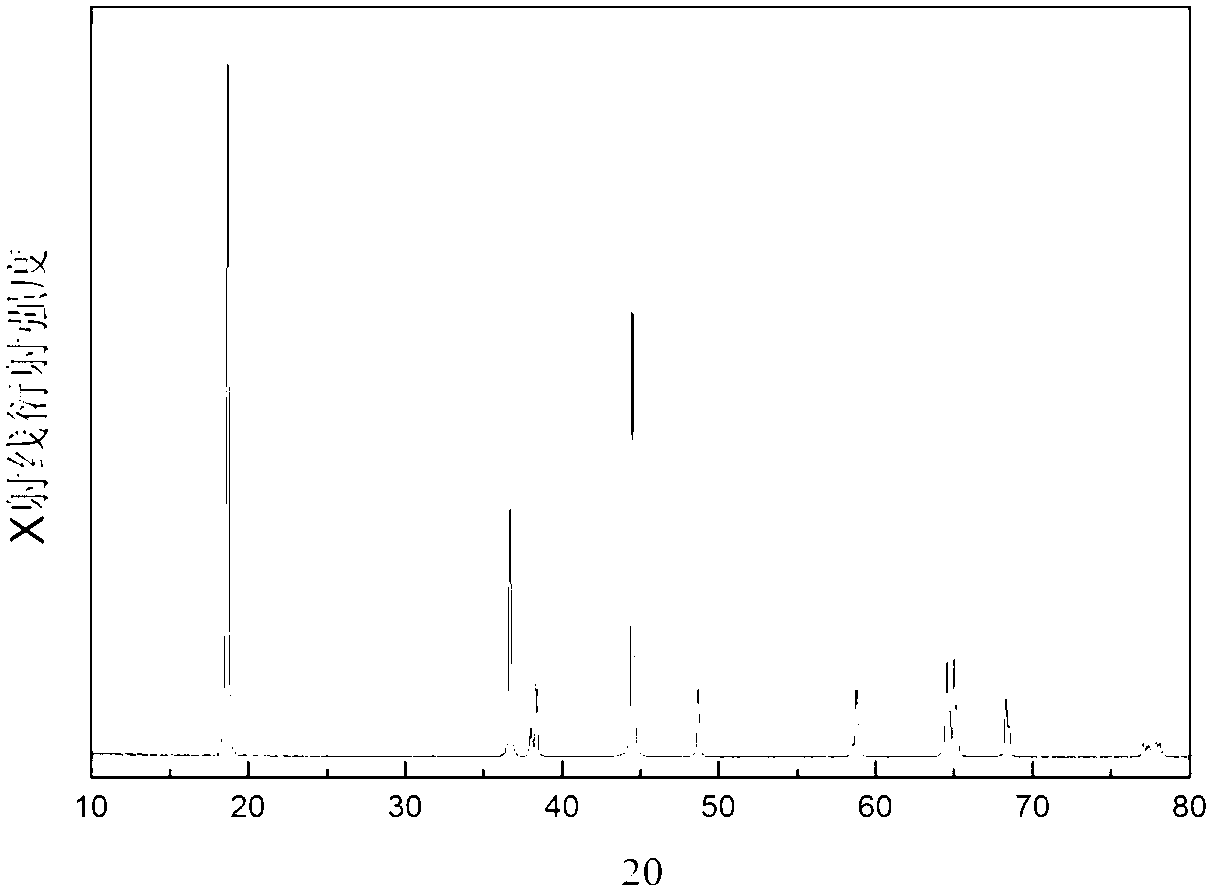

Embodiment 2

[0037] (1) Preparation of aluminum sol: weigh 37.5g (ie 0.1mol) Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make a 1mol / L aqueous solution. After adding 100mL of 1mol / L ammonia water into the three-necked flask, it was placed in a water bath at 85°C and stirred continuously, and then the aforementioned aluminum nitrate solution was slowly dropped into it to form Precipitation; after reacting for 2 hours, add 1 mol / L nitric acid solution to it, control the pH value at 6, slowly peptize the precipitate, continue stirring to age for 20 hours, and obtain a clear AlOOH sol.

[0038] (2), (3) steps are the same as in Example 1, and the chemical composition is LiNi 0.80 co 0.15 al 0.05 o 2 nickel cobalt lithium aluminate powder.

[0039] After testing, the obtained nickel cobalt lithium aluminate tap density is 2.22g / cm 3 , the average particle size is 10.08μm, the discharge capacity is 177mAh / g, the first-round charge-discharge efficiency is 90%, and the capacity r...

Embodiment 3

[0041] (1) The preparation of aluminum sol is the same as in Example 1 (1);

[0042] (2) Preparation of nickel-cobalt-aluminum hydroxide precursor: when preparing the mixed salt solution of nickel sulfate and cobalt sulfate, mix according to n(Ni) / n(Co)=0.821:0.179, and the others are the same as in Example 1 (2);

[0043] (3) With embodiment 1 (3), obtain chemical composition and be LiNi 0.78 co 0.17 al 0.05 o 2 nickel cobalt lithium aluminate powder.

[0044] After testing, the obtained nickel cobalt lithium aluminate tap density is 2.26g / cm 3 , the average particle size is 10.28μm, the discharge capacity is 175mAh / g, the first cycle charge and discharge efficiency is 89%, and the capacity retention rate after 50 cycles is 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com