Method for preparing spherical alpha-phase alumina

A technology of spherical alumina and phase alumina, which is applied in the preparation of alumina/hydroxide, etc., can solve the problems of limitation and difficulty in preparing α-phase alumina, and achieve high filling capacity, short preparation time and high fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

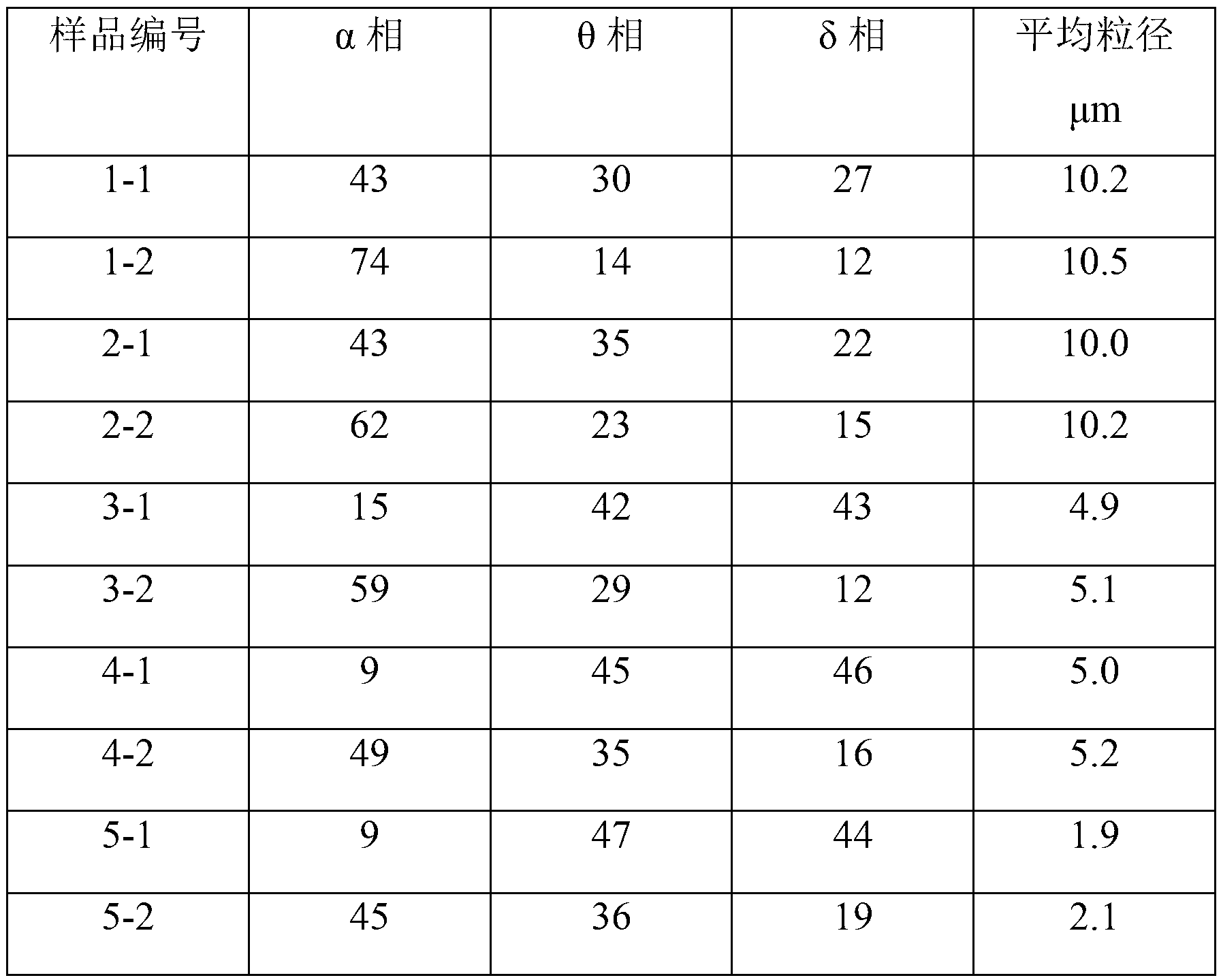

[0017] Commercially available α-alumina was crushed to an average particle size of 10 μm. As a raw material, the raw material was put into a triple tube burner and the temperature was controlled at 2100°C to 2300°C for melting and spheroidization to obtain Test Sample 1-1. The test sample 1-1 was put into the burner again and the flame temperature was controlled at 1800°C to 2000°C for heat treatment to obtain the test sample 1-2. The obtained samples were measured by XRD, and the content of each crystal phase was calculated from the intensity of each crystal characteristic peak and listed in Table 1.

Embodiment 2

[0019] Commercially available γ-alumina was crushed to an average particle size of 10 μm. As a raw material, the raw material was put into a triple tube burner and the temperature was controlled at 2100°C to 2300°C for melting and spheroidization to obtain test sample 2-1. The test sample 2-1 was put into the burner again, and the flame temperature was controlled at 1800°C to 2000°C for heat treatment to obtain the test sample 2-2. The obtained samples were measured by XRD, and the content of each crystal phase was calculated from the intensity of each crystal characteristic peak and listed in Table 1.

Embodiment 3

[0021] Commercially available α-alumina was crushed to an average particle size of 5 μm. As a raw material, the raw material was put into a triple tube burner and the temperature was controlled at 2100°C to 2300°C for melting and spheroidization to obtain test sample 3-1. The test sample 3-1 was put into the burner again and the flame temperature was controlled at 1800°C to 2000°C for heat treatment to obtain the test sample 3-2. The obtained samples were measured by XRD, and the content of each crystal phase was calculated from the intensity of each crystal characteristic peak and listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com