Preparation method of bacterial cellulose-based carbon aerogel

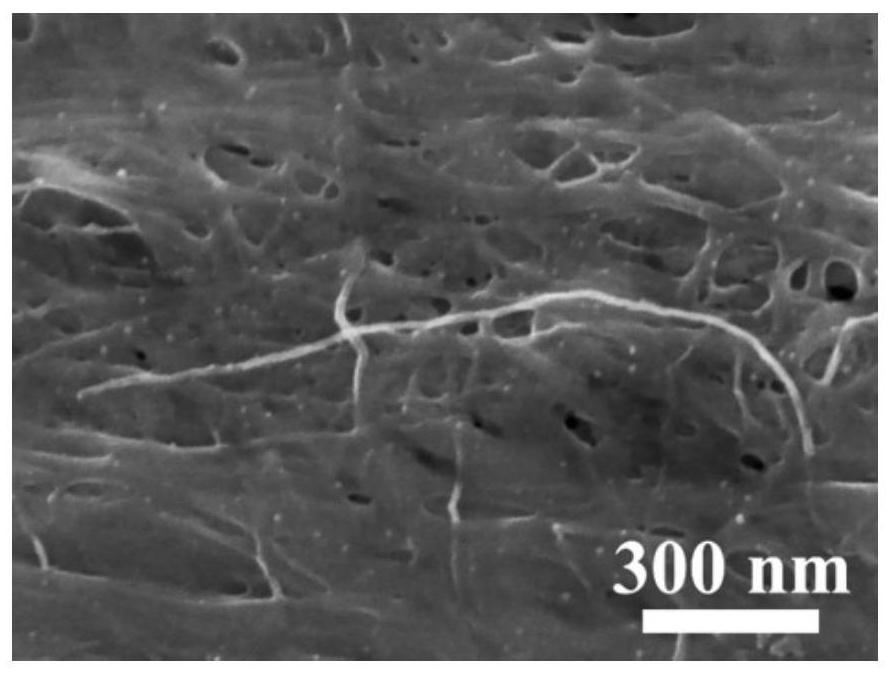

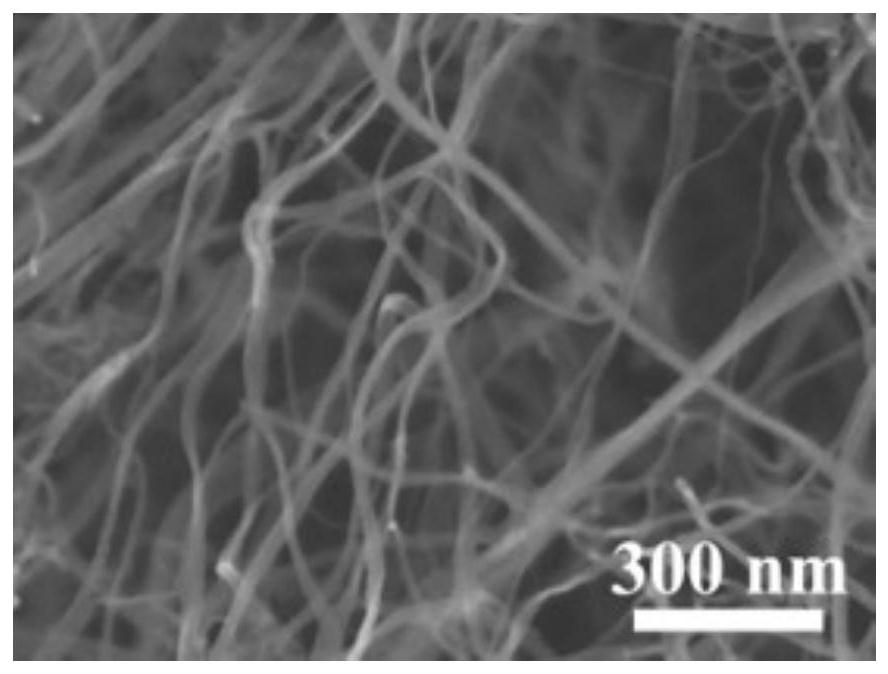

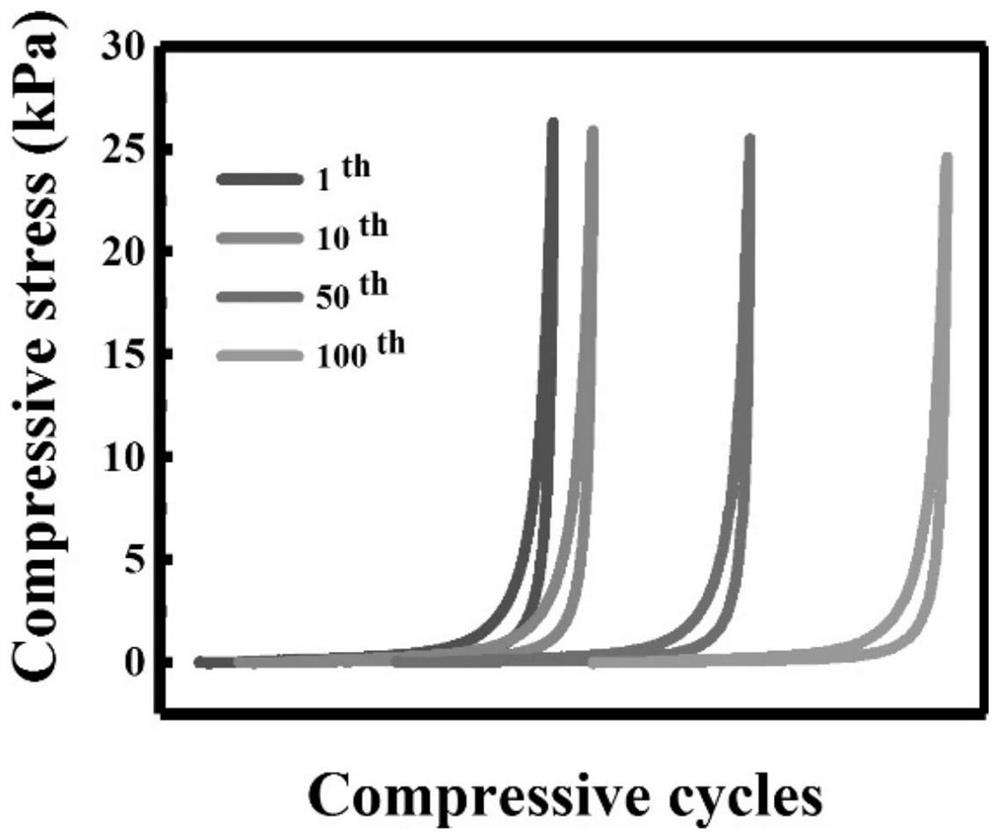

A bacterial cellulose and aerogel technology, applied in carbon preparation/purification, sol preparation, chemical instruments and methods, etc., can solve problems such as structural collapse and porous network structure, reduce structural shrinkage, and optimize graphite Chemical structure, conductivity, and the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Mix and dissolve 0.016g TEMPO and 0.1g NaBr in 100mL deionized water, and stir for 1 hour to obtain a mixed solution;

[0056] (2) Add 14mg of BC dispersion to the above mixed solution, then add 2mL of 6-14% NaClO aqueous solution and 2mL of hydrochloric acid at room temperature, then add 0.5M NaOH aqueous solution to react, and continue to add dropwise to make the pH of the reaction solution Keep it at about 10.0, and the obtained reaction product is thoroughly washed with deionized water;

[0057] (3) Add 25mL of a mixed solution of water and tert-butanol (5:1, v / v), and stir at room temperature for 2 hours to form a uniform hydrogel;

[0058] (4) The obtained hydrogel was pre-frozen in liquid nitrogen for 24h, then put into a vacuum freeze dryer for drying treatment for 48h, then put the dried aerogel into a tube-type resistance furnace for high-temperature carbonization, and then 2 In the atmosphere, the temperature was raised to 800°C at a rate of 3°C / min, kep...

Embodiment 2

[0068] (1) Mix and dissolve 0.016g TEMPO and 0.1g NaBr in 100mL deionized water, and stir for 1 hour to obtain a mixed solution;

[0069] (2) Add 14mg of BC dispersion to the above mixed solution, then add 6-14% NaClO aqueous solution 2mL and hydrochloric acid 2mL to react at room temperature, then add 0.5M NaOH aqueous solution to react, and continue to add dropwise to make the reaction solution The pH value is kept at about 10.0, and the obtained reaction product is thoroughly washed with deionized water;

[0070] (3) Add 25mL of a mixed solution of water and tert-butanol (8:1, v / v), and stir at room temperature for 2 hours to form a uniform hydrogel;

[0071] (4) The obtained hydrogel was pre-frozen in liquid nitrogen for 24h, then put into a vacuum freeze dryer for drying treatment for 48h, then put the dried aerogel into a tube-type resistance furnace for high-temperature carbonization, and then 2 In the atmosphere, the temperature was raised to 800°C at a rate of 3°C / mi...

Embodiment 3

[0074] (1) Mix and dissolve 0.016g TEMPO and 0.1g NaBr in 100mL deionized water, and stir for 1 hour to obtain a mixed solution;

[0075] (2) Add 14mg of BC dispersion to the above mixed solution, then add 6-14% NaClO aqueous solution 2mL and hydrochloric acid 2mL to react at room temperature, then add 0.5M NaOH aqueous solution to react, and continue to add dropwise to make the reaction solution The pH value is kept at about 10.0, and the obtained reaction product is thoroughly washed with deionized water;

[0076] (3) Add 25 mL of a mixed solution of water and tert-butanol (3:1, v / v), and stir at room temperature for 2 hours to form a uniform hydrogel;

[0077] (4) The obtained hydrogel was pre-frozen in liquid nitrogen for 24h, then put into a vacuum freeze dryer for drying treatment for 48h, then put the dried aerogel into a tube-type resistance furnace for high-temperature carbonization, and then 2 In the atmosphere, the temperature was raised to 800°C at a rate of 3°C / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com