Preparation method of Ni-MOF electrode material

An electrode material, nickel nitrate technology, applied in the field of materials science, can solve the problems of rare supercapacitor electrodes, and achieve the effects of good electrochemical performance, high rate performance and high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a Ni-MOF electrode material, specifically comprising the steps of:

[0023] (1) with N,N-dimethylformamide (DMF) as solvent, preparation concentration is the PTA / DMF solution of 0.005mol / l, with water as solvent, preparation concentration is the nickel nitrate aqueous solution of 0.0075mol / l; ( 2) The above-mentioned nickel nitrate aqueous solution is added in the PTA / DMF solution at a speed of 3ml / min, and the volume ratio of the two is controlled to be 2-1. After dissolving and stirring for 1h, the total concentration of PTA obtained is 0.0016mol / L. Precursor solution with a total concentration of 0.0025 mol / l.

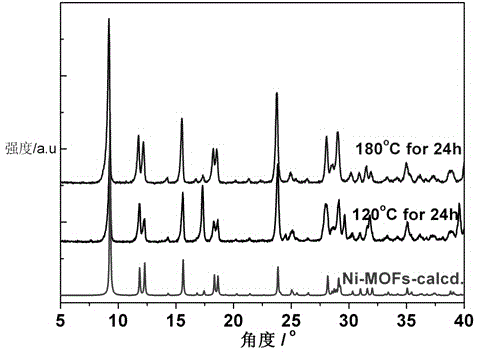

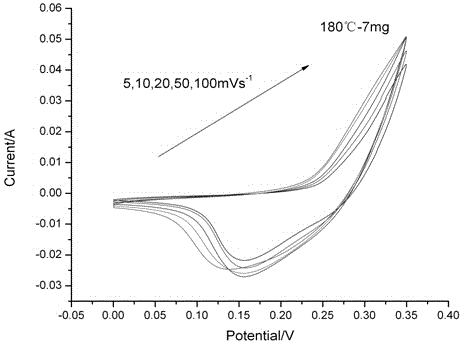

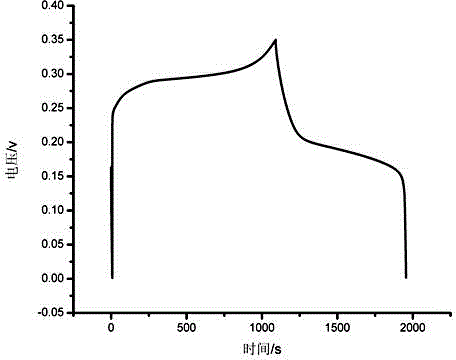

[0024] (3) The precursor solution in (2) was subjected to solvothermal reaction in a hydrothermal kettle at 120°C for 24 hours, and the obtained green precipitate was washed by centrifugation with DMF and absolute ethanol, filtered, and dried at 80°C to obtain Ni-MOF electrode material with good electrochemical performance.

[0025] T...

Embodiment 2

[0028] A method for preparing a Ni-MOF electrode material, specifically comprising the steps of:

[0029] (1) with N,N-dimethylformamide (DMF) as solvent, preparation concentration is the PTA / DMF solution of 0.01mol / l, with water as solvent, preparation concentration is the nickel nitrate aqueous solution of 0.05mol / l; ( 2) The above-mentioned nickel nitrate aqueous solution is added in the PTA / DMF solution at a speed of 3ml / min, and the volume ratio of the two is controlled to be 2-1. After dissolving and stirring for 1h, the total concentration of PTA obtained is 0.003mol / L. Precursor solution with a total concentration of 0.016 mol / l.

[0030] (3) The precursor solution in (2) was subjected to solvothermal reaction in a hydrothermal kettle at 140°C for 24 hours, and the obtained green precipitate was washed by centrifugation with DMF and absolute ethanol, filtered, and dried at 80°C to obtain Ni-MOF electrode material with good electrochemical performance.

[0031] The X-...

Embodiment 3

[0034] A method for preparing a Ni-MOF electrode material, specifically comprising the steps of:

[0035] (1) with N,N-dimethylformamide (DMF) as solvent, preparation concentration is the PTA / DMF solution of 0.015mol / l, with water as solvent, preparation concentration is the nickel nitrate aqueous solution of 0.0225mol / l; ( 2) Add the above-mentioned nickel nitrate aqueous solution into the PTA / DMF solution at a rate of 3ml / min, control the volume ratio of the two to 2-1, dissolve and stir for 1-2 hours, and obtain a total concentration of PTA of 0.005mol / L, nitric acid The total concentration of nickel is 0.0075 mol / l in the precursor solution.

[0036] (3) The precursor solution in (2) was subjected to solvothermal reaction in a 160°C hydrothermal kettle for 24 hours, and the resulting green precipitate was centrifugally washed with DMF and absolute ethanol, filtered, and dried at 80°C to obtain Ni-MOF electrode material with good electrochemical performance.

[0037] The X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com