CdS @ Ni3S2 core-shell heterostructure composite material, preparation method and application thereof

A technology of heterostructures and composite materials, applied in the field of composite materials, can solve the problems affecting the application of supercapacitors, poor cycle stability, small capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

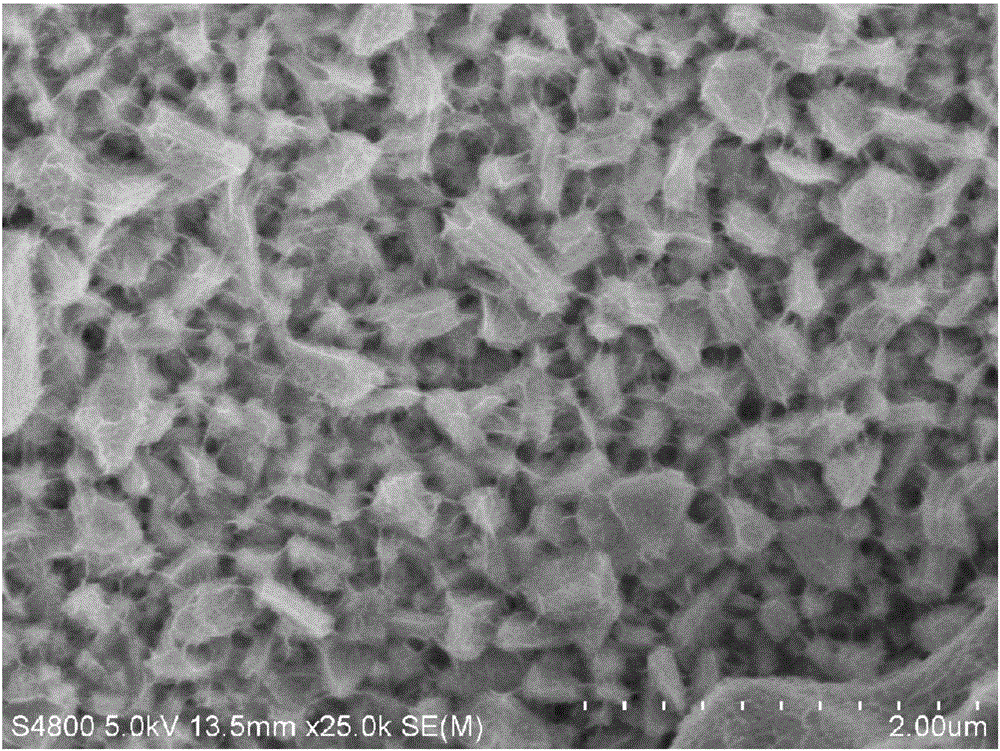

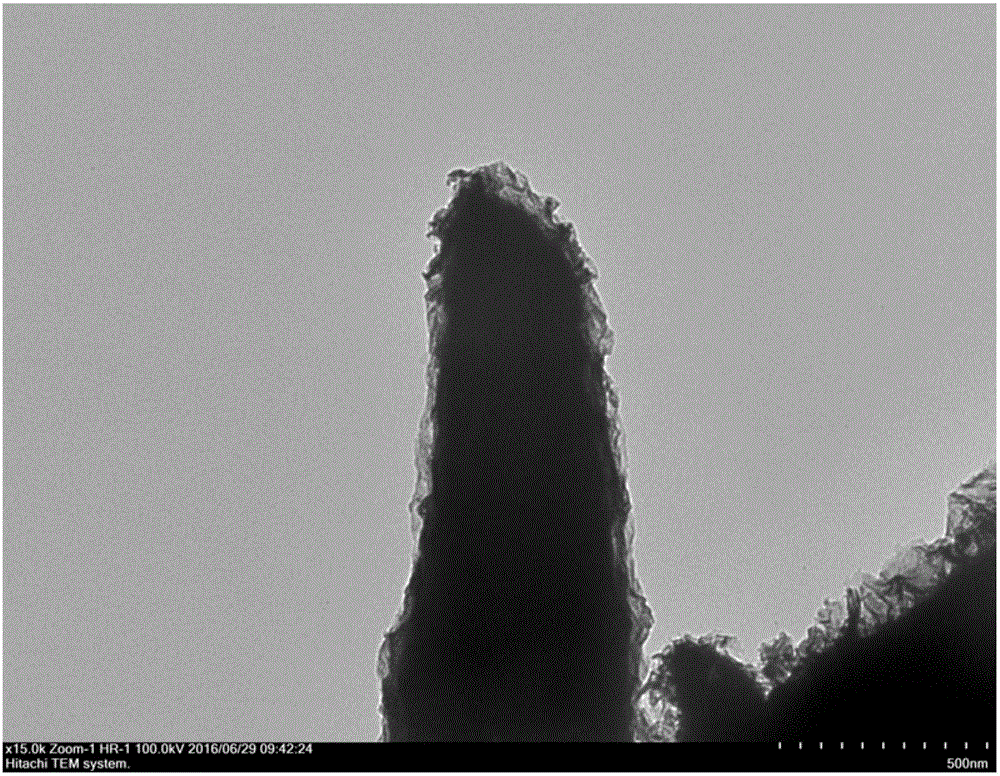

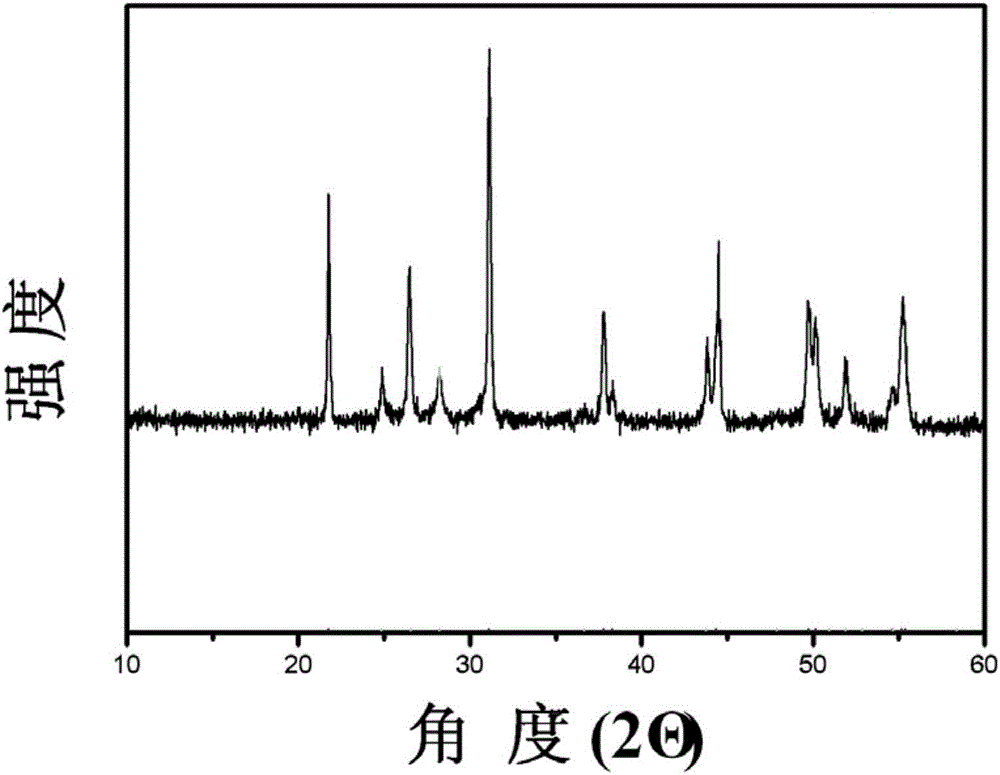

[0021] The invention provides a CdS@Ni 3 S 2 A method for preparing a core-shell heterostructure composite material, comprising:

[0022] 1) nickel foam is placed in acid solution for acidification;

[0023] 2) Put the acidified nickel foam in the closed reaction solution for hydrothermal reaction, then wash and dry to prepare CdS@Ni 3 S 2 Core-shell heterostructure composites;

[0024] Wherein, the reaction solution contains water, cadmium sulfide and thiourea.

[0025] In the above preparation method, the specific type of acid solution can be selected in a wide range, but in order to make the surface of foamed nickel clean, and then make the prepared CdS@Ni 3 S 2 The core-shell heterostructure composite material has more excellent capacitance, specific capacitance and stability. Preferably, in step 1), the acid solution is selected from one or more of hydrochloric acid solution, sulfuric acid solution or phosphoric acid solution.

[0026] In the above preparation meth...

Embodiment 1

[0039] 1) Pretreatment of foamed nickel: Soak foamed nickel (2cm×2cm, 1.3mm, weight 0.1488g) in 2mol / L hydrochloric acid solution for 20 minutes and then wash it with deionized water at 25°C 10min;

[0040] 2) Dissolve 0.25mmol cadmium sulfide and 1mmol thiourea in 35ml deionized water and stir for 30 minutes to form a mixed solution, then immerse the acidified nickel foam in the mixed solution, then transfer the reaction system to a 50ml reactor and seal it Carry out hydrothermal reaction (reaction at 160°C for 12h), take it out after cooling, wash with deionized water and absolute ethanol three times respectively, and dry at 60°C to prepare CdS@Ni 3 S 2 Core-shell heterostructure composite A1.

Embodiment 2

[0042] Prepare CdS@Ni according to the method of Example 1 3 S 2 Core-shell heterostructure composite material A2, the difference is: nickel foam meets the following conditions: the specification is 2cm×3cm, the thickness is 1mm, and the weight is 0.148g; the content of cadmium sulfide in the mixed solution is 0.12mmol, and the content of thiourea is 0.8mmol; the condition of the hydrothermal reaction is to react at 150°C for 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com