CoNi2S4/graphene composite material for supercapacitor and preparation method thereof

A technology of supercapacitors and composite materials, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc. the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take Co(NO 3 ) 2 ·6H 2 O is 1mmol, Ni(NO 3 ) 2 ·6H 2 O is 3mmol, CH 3 CSNH 2 Dissolve 6mmol in 40ml ethanol.

[0025] 2) Dissolve the prepared 10mgGO in 20ml of ethanol and sonicate for 1.5h, then add the CoNi2S4 solution prepared in 1) and transfer it to a 100ml tetrafluoroethylene-lined reactor for reaction. The hydrothermal reaction time is 16h, and the hydrothermal temperature is 180°C.

[0026] 3) Wash several times with deionized water and freeze-dry at -70°C for 72 hours to obtain the composite material CoNi 2 S 4 / rGO-1;

[0027] 4) The composite material CoNiS 4Grind / rGO-1 finely, mix the composite material, acetylene black, and polytetrafluoroethylene at a mass ratio of 8:1:1, add a small amount of ethanol as a solvent, stir magnetically, bake until it becomes sticky, and apply an appropriate amount on the nickel foam 5) 3M KOH solution was used as the electrolyte, and a three-electrode system was selected to measure its electrochemical perform...

Embodiment 2

[0030] 1) Take Co(NO 3 ) 2 ·6H 2 O is 3mmol, Ni(NO 3 ) 2 ·6H 2 O is 5mmol, CH 3 CSNH 2 Dissolve 10mmol in 50ml ethanol.

[0031] 2) Dissolve 60mg of GO prepared in 40ml of ethanol and sonicate for 1.5h, and then the CoNi prepared in 1) 2 S 4 The solution was added and transferred to a 100ml tetrafluoroethylene-lined reactor for reaction. The hydrothermal reaction time was 16 hours, and the hydrothermal temperature was 180°C.

[0032] Description: the remaining 3) to 5) steps are the same as in Example 1, and will not be described in detail to obtain CoNi 2 S 4 / rGO-2 composites, and make electrodes for electrochemical performance testing.

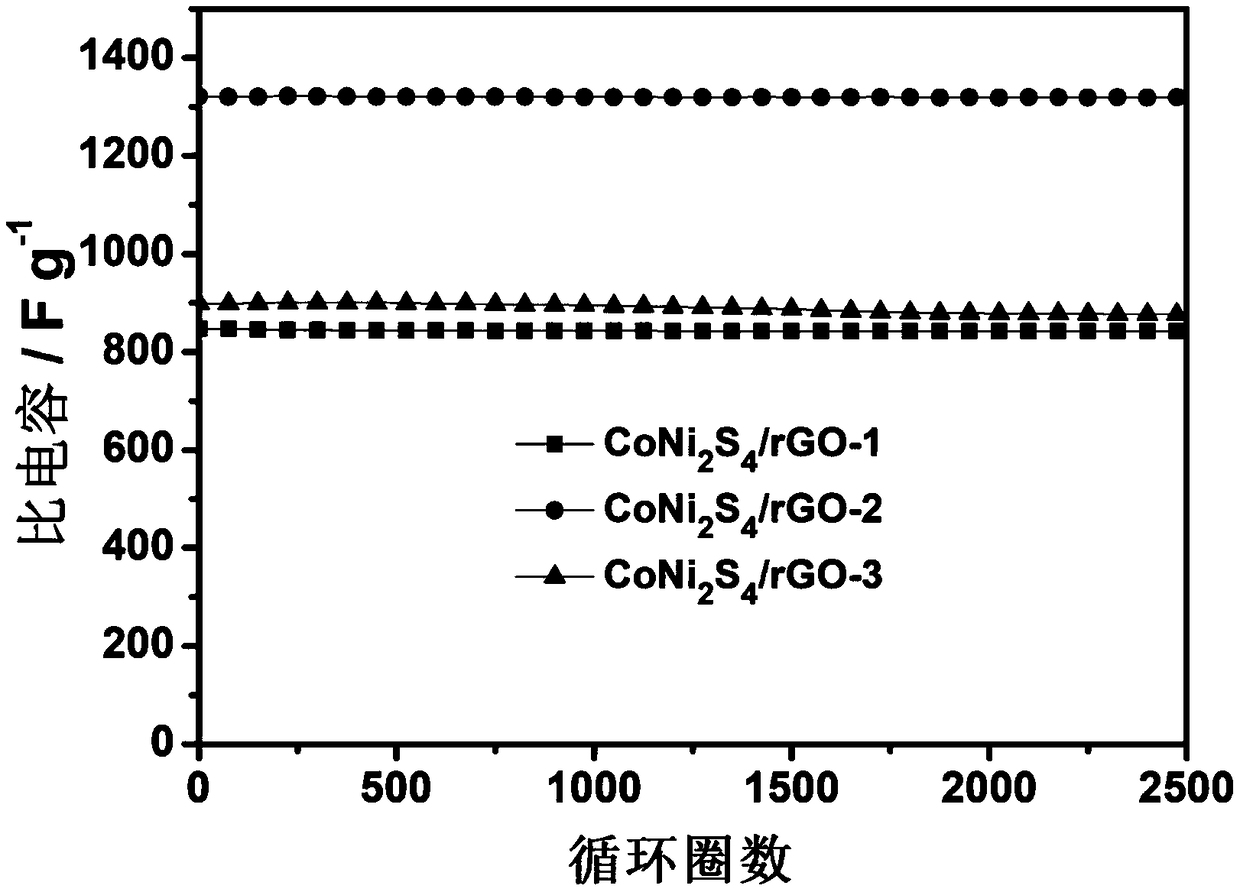

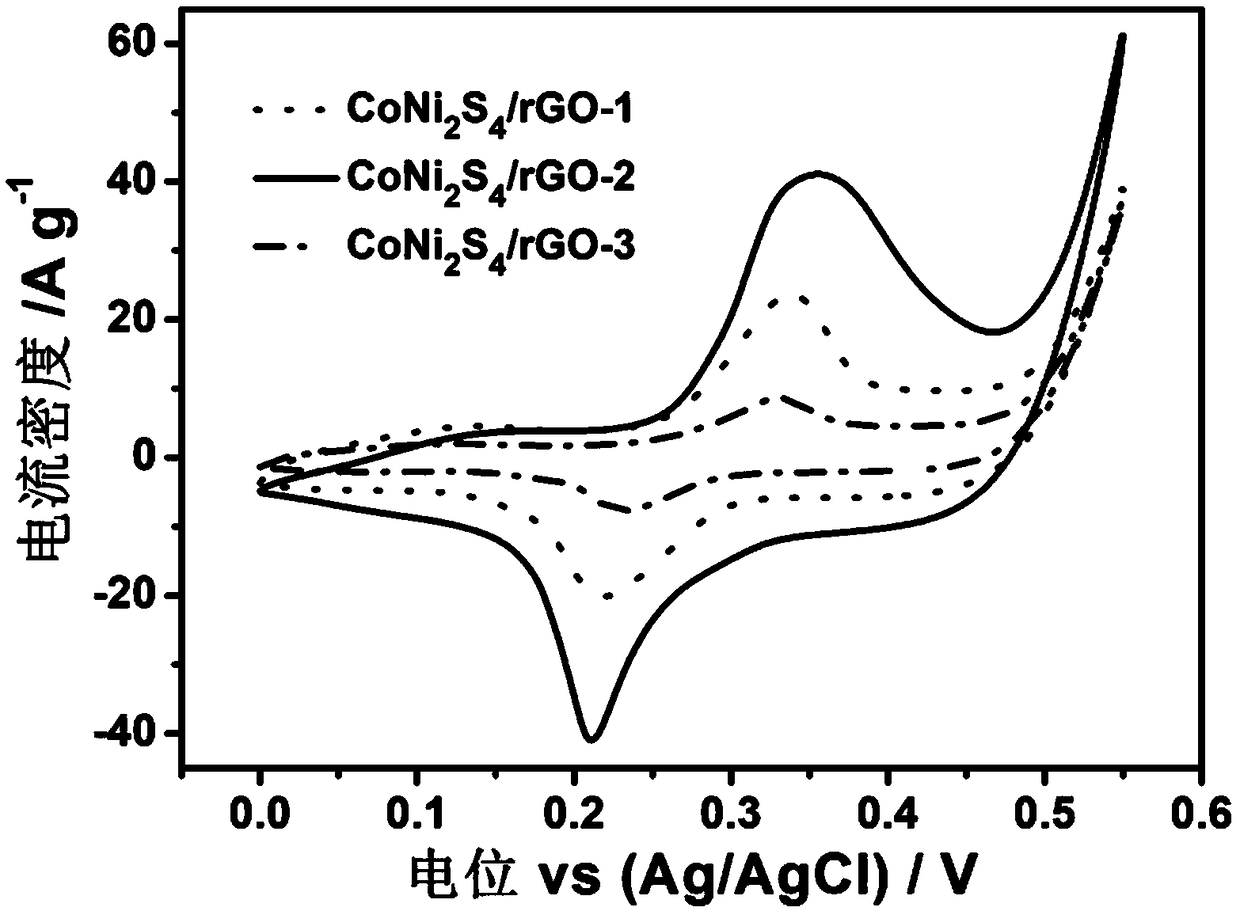

[0033] Figure 4 , Figure 5 It is the CoNi prepared by Example 2 of the present invention 2 S 4 / A scanning electron microscope image of a graphene nanocomposite, which shows the composite as a flower. Image 6 It is the CoNi prepared by Example 2 of the present invention 2 S 4 / Chart-discharge cycle diagram of graphene ...

Embodiment 3

[0036] 1) Take Co(NO 3 ) 2 ·6H 2 O is 3mmol, Ni(NO 3 ) 2 ·6H 2 O is 5mmol, CH 3 CSNH 2 Dissolve 10mmol in 50ml ethanol.

[0037] 2) Dissolve 80mg of GO prepared in 40ml of ethanol and sonicate for 1.5h, and then the CoNi prepared in 1) 2 S 4 The solution was added and transferred to a 100ml tetrafluoroethylene-lined reactor for reaction. The hydrothermal reaction time was 16 hours, and the hydrothermal temperature was 180°C.

[0038] Description: the remaining 3) to 5) steps are the same as in Example 1, and will not be described in detail to obtain CoNi 2 S 4 / rGO-3 composites, and make electrodes for electrochemical performance testing.

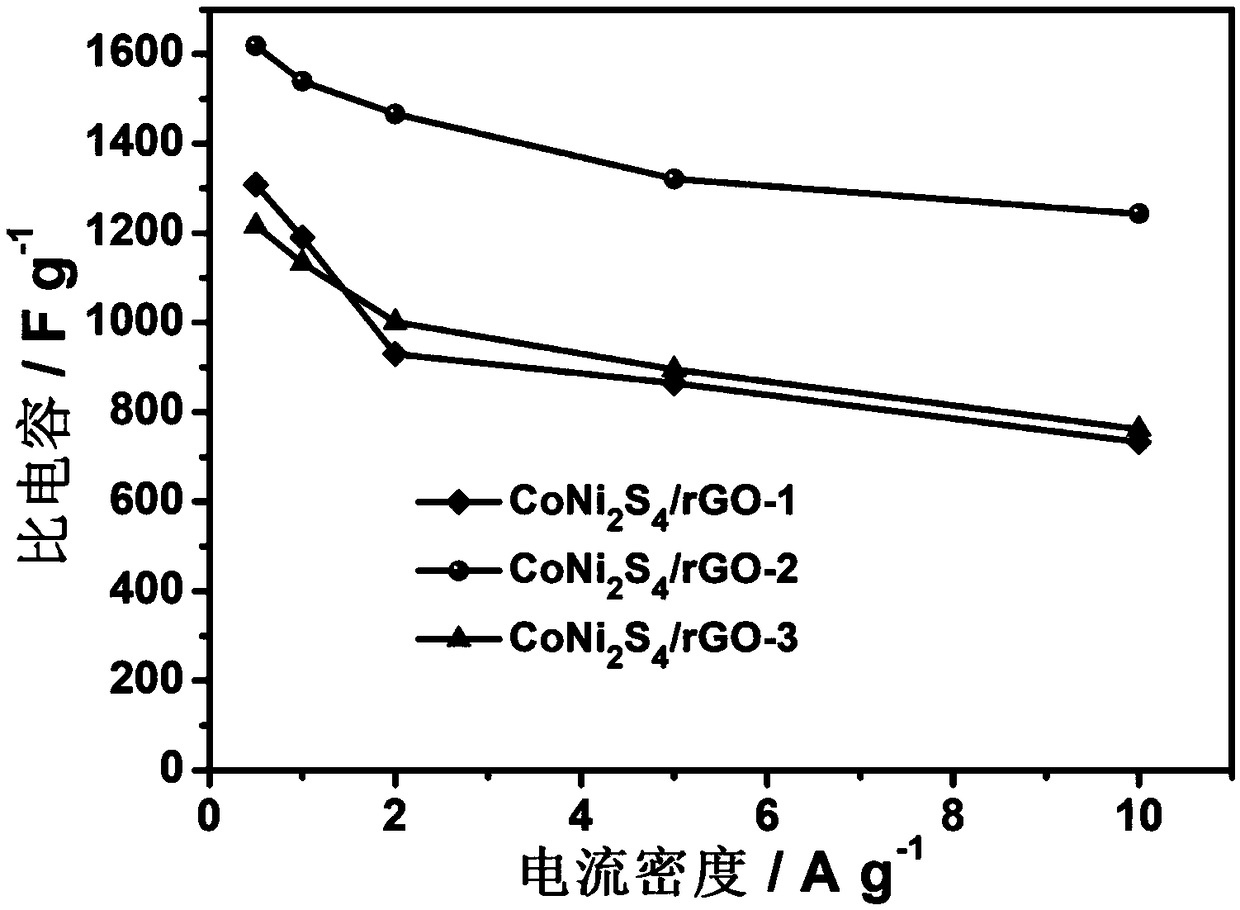

[0039] Through the electrochemical performance test, the charge and discharge test is carried out under constant current, from figure 1 Available in, Example 3 at 0.5A·g -1 Under the current density, the specific capacitance is 1216F·g -1 . at 1A·g -1 Under the current density, the specific capacitance is 1133F·g -1 . at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com