Epoxy resin film for nano silicon dioxide modified rfi and preparation method thereof

A technology of nano-silica and epoxy resin, which is applied in the field of inorganic/organic composite materials, can solve problems such as resin films that have not yet been seen, and achieve the effects of reducing the number of hydroxyl groups, improving the ease of agglomeration, and reducing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

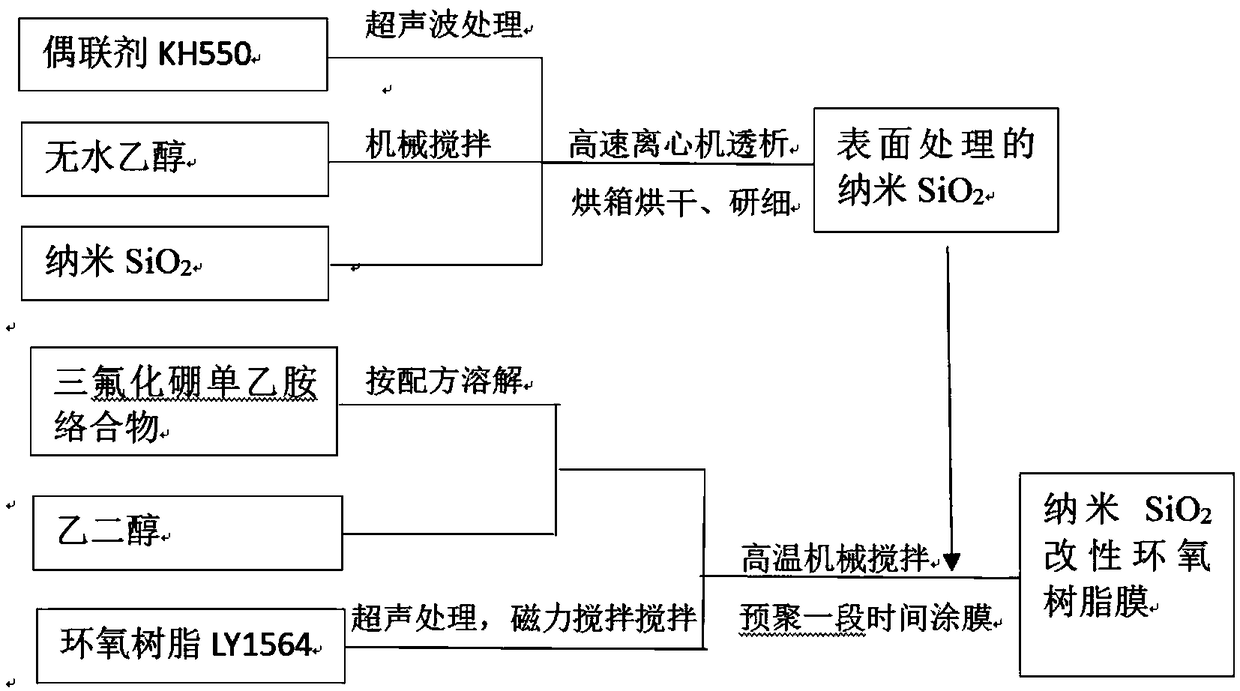

Method used

Image

Examples

Embodiment 1

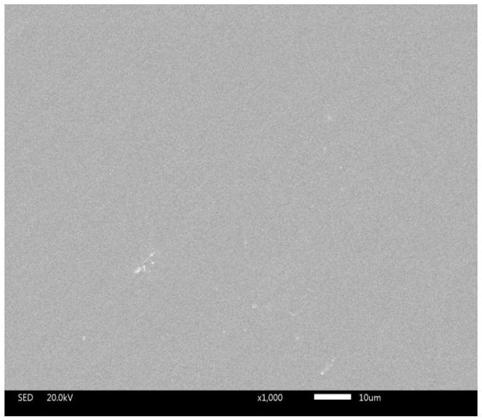

[0034] Embodiment 1: the preparation of epoxy resin film

[0035] Components: epoxy resin LY1564 (g): 100, boron trifluoride ethylamine complex (g): 3, ethylene glycol (g): 15.

[0036] Step 1: Preparation of prepolymer of epoxy resin and boron trifluoride ethylamine complex: prepare a diluent according to the ratio of high-temperature latent curing agent boron trifluoride ethylamine complex and ethylene glycol. Then add the diluted solution into the epoxy resin, heat up to 80° C. in a numerically controlled ultrasonic cleaner, and stir evenly with an electric stirrer to obtain an epoxy resin prepolymer solution.

[0037]Step 2 to prepare epoxy resin film: add the resin prepolymer solution obtained in step 1 to a constant temperature heating magnetic stirrer, heat the mixed solution to 120°C, control the temperature at 120°C for a period of time (5min ~ 10min), when the ring When the temperature of the oxygen prepolymer solution rises above 120°C to 125°C, the epoxy resin mix...

Embodiment 2

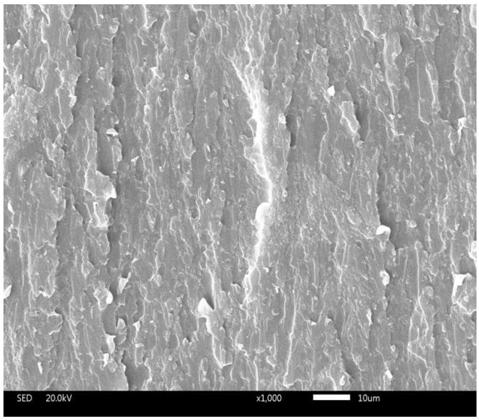

[0045] Example 2: Nano-SiO 2 Preparation of modified epoxy resin film

[0046] Components: epoxy resin LY1564 (g): 100, boron trifluoride ethylamine complex (g): 3, ethylene glycol (g): 15. nano-SiO 2 (gram): 1, coupling agent KH-550 (gram): 0.05, absolute ethanol (gram): 10.

[0047] Step 1: Preparation of prepolymer of epoxy resin and boron trifluoride ethylamine complex: prepare a diluent according to the ratio of high-temperature latent curing agent boron trifluoride ethylamine complex and ethylene glycol. Then add the diluent into the epoxy resin, heat up to 80°C in a numerically controlled ultrasonic cleaner, and stir evenly with an electric stirrer.

[0048] Step 2 Preparation of modified nano-SiO 2 : Nano-SiO 2 Prepare a mixed solution with anhydrous ethanol solution according to the ratio, then add the coupling agent KH550 to the mixed solution, and ultrasonically treat it in a numerically controlled ultrasonic cleaner for 1 hour to make the coupling agent and na...

Embodiment 3

[0057] Example 3: Nano-SiO 2 Preparation of modified epoxy resin film

[0058] Components: epoxy resin LY1564 (g): 100, boron trifluoride ethylamine complex (g): 3, ethylene glycol (g): 15. nano-SiO 2 (gram): 2, coupling agent KH-550 (gram): 0.1, absolute ethanol (gram): 20.

[0059] nano-SiO 2 The preparation steps of the modified epoxy resin film are the same as in Example 2.

[0060] The product performance of embodiment 3 is as follows:

[0061] Performance of cured resin cast body:

[0062] Tensile strength (MPa): 56.96 (GB / T 2567-2008);

[0063] Bending strength (MPa): 89.61 (GB / T 2567-2008);

[0064] Impact strength (kJ / m 2 ): 18.35 (GB / T 2567-2008);

[0065] Glass transition temperature Tg (°C): 96.9 (DMA method).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com