Array carbon nano-tube/carbon fiber-based flexible composite electrode material and preparation method thereof

A carbon nanotube and composite electrode technology, which is applied in the directions of carbon fiber, fiber processing, circuits, etc., can solve the problems of poor capacitance performance, power characteristics and frequency response characteristics of array carbon nanotube/carbon fiber-based flexible composite electrode materials that have not yet been seen. Affect the supercapacitor rate performance and other issues, and achieve the effects of good cycle stability and mechanical properties, excellent rate performance, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

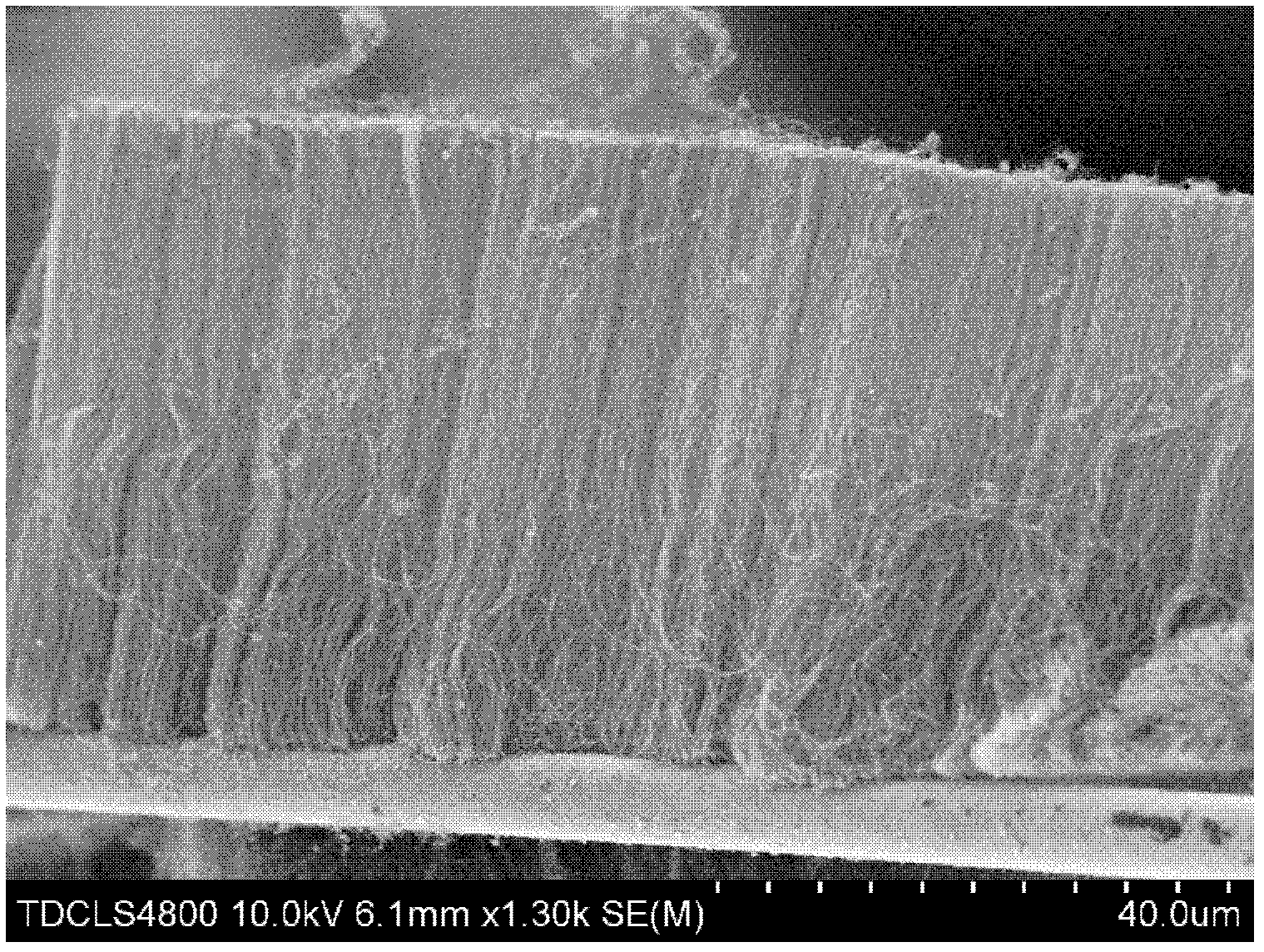

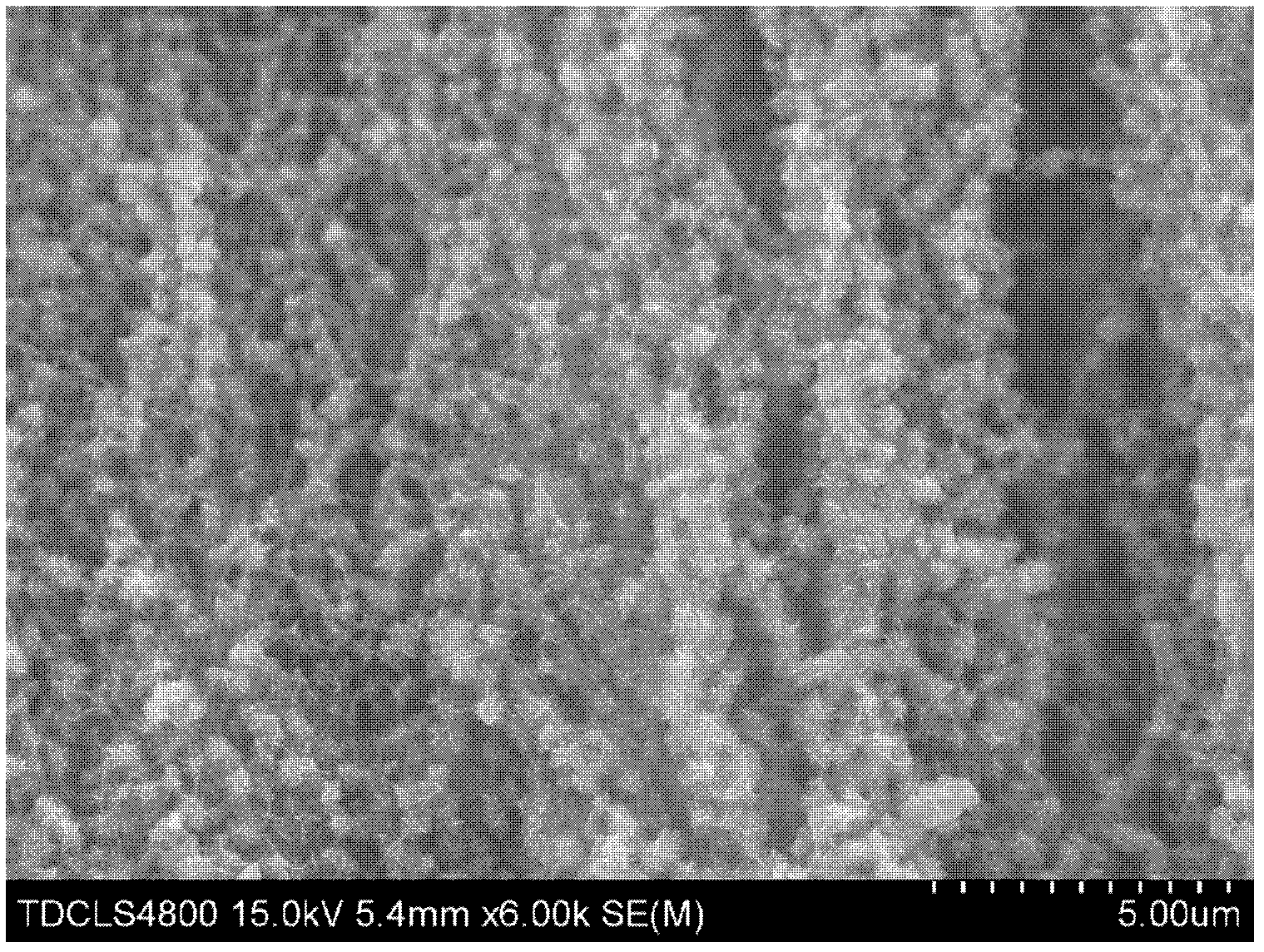

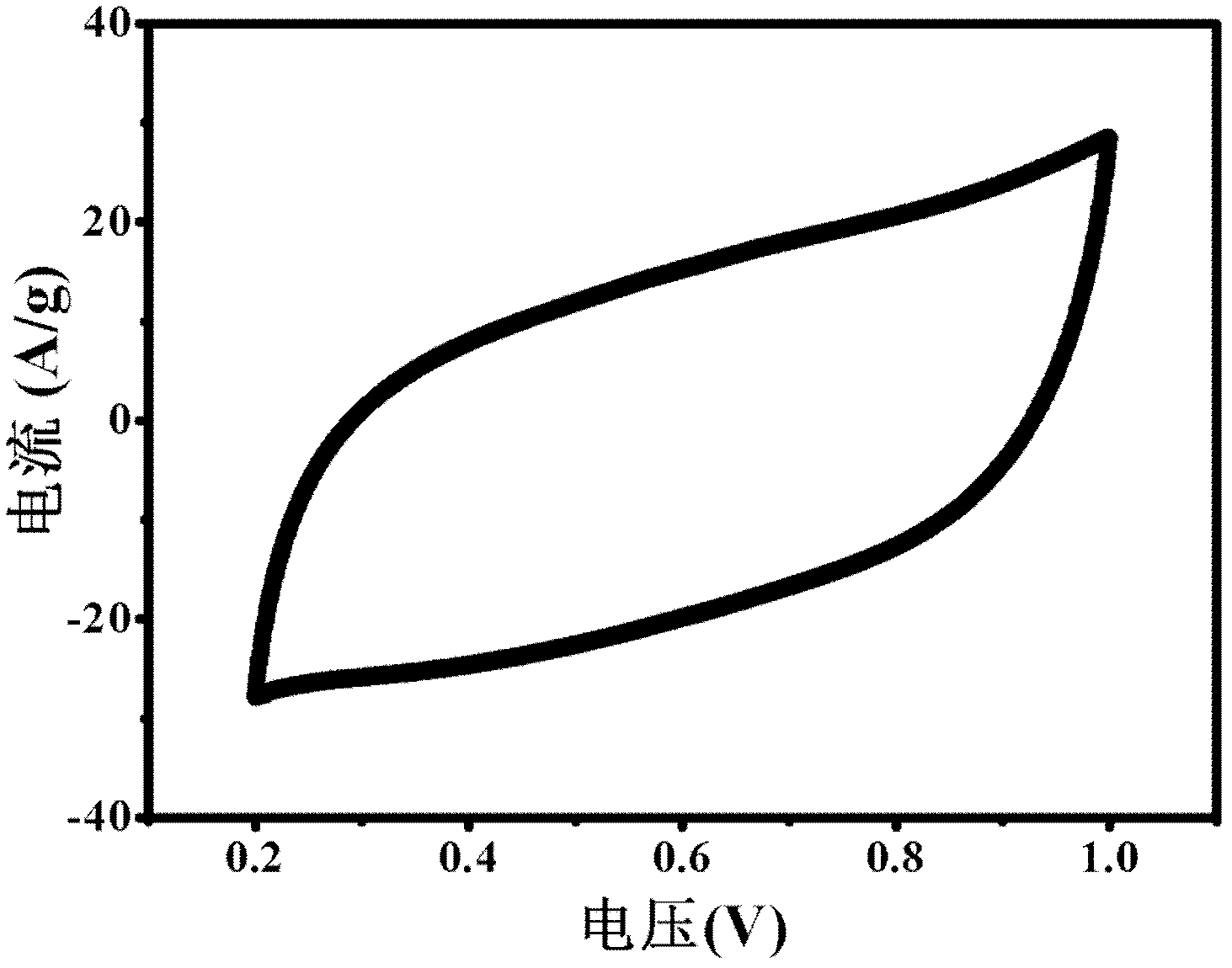

[0025] Put a three-dimensional carbon fiber braid with a plane size of 2cm×2cm and a thickness of 0.2cm in a tube-type high-temperature furnace. 3 After the air in the tube is exhausted by argon gas at a flow rate of / min, the temperature of the furnace tube is raised to 800°C, and after 1 hour of heat preservation, it is taken out after being lowered to room temperature under the protection of argon gas. Soak the treated three-dimensional carbon fiber braid in a mixed solution of 0.46g tetraethyl orthosilicate, 0.74g silicon tetrachloride and 16.34g xylene for 10 minutes. It was then exposed to water vapor for 10 minutes and then dried under vacuum at a temperature of 60°C. After drying, put the three-dimensional carbon fiber braided body into a high-temperature tube furnace again, at a gas flow rate of 300 cm 3 / min under the protection of argon to raise the temperature to 1000°C, keep the temperature for 10 minutes, and then drop to room temperature under the protection of...

Embodiment 2

[0029] Put a three-dimensional carbon fiber braid with a plane size of 2cm×2cm and a thickness of 0.2cm in a tube-type high-temperature furnace. 3 After removing the air in the tube with argon gas at a flow rate of / min, the temperature of the furnace tube was raised to 850°C, and after 2 hours of heat preservation, it was taken out after falling to room temperature under the protection of argon gas. Soak the treated three-dimensional carbon fiber braid in a mixed solution of 0.46g tetraethyl orthosilicate, 0.74g silicon tetrachloride and 16.34g xylene for 10 minutes. It was then exposed to water vapor for 10 minutes and then dried under vacuum at a temperature of 60°C. After drying, put the three-dimensional carbon fiber braided body into a high-temperature tube furnace again, at a gas flow rate of 300 cm 3 / min under the protection of argon to raise the temperature to 1000°C, keep the temperature for 10 minutes, and then drop to room temperature under the protection of argon...

Embodiment 3

[0033] Put a three-dimensional carbon fiber braid with a plane size of 2cm×2cm and a thickness of 0.2cm in a tube-type high-temperature furnace. 3 After removing the air in the tube with argon gas at a flow rate of / min, the temperature of the furnace tube was raised to 900°C, and after 1 hour of heat preservation, it was taken out after being lowered to room temperature under the protection of argon gas. Soak the treated three-dimensional carbon fiber braid in a mixed solution of 0.46g tetraethyl orthosilicate, 0.74g silicon tetrachloride and 16.34g xylene for 10 minutes. It was then exposed to water vapor for 10 minutes and then dried under vacuum at a temperature of 60°C. After drying, put the three-dimensional carbon fiber braided body into a high-temperature tube furnace again, at a gas flow rate of 300 cm 3 / min under the protection of argon to raise the temperature to 1000°C, keep the temperature for 10 minutes, and then drop to room temperature under the protection of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com