Pre-treating process for high-voltage aluminum foil corrosion

A technology of anode aluminum foil and pretreatment liquid, applied in electrical components, electrolytic capacitors, capacitors, etc., can solve problems such as small specific volume, achieve good mechanical strength, and improve the effect of corrosion area expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

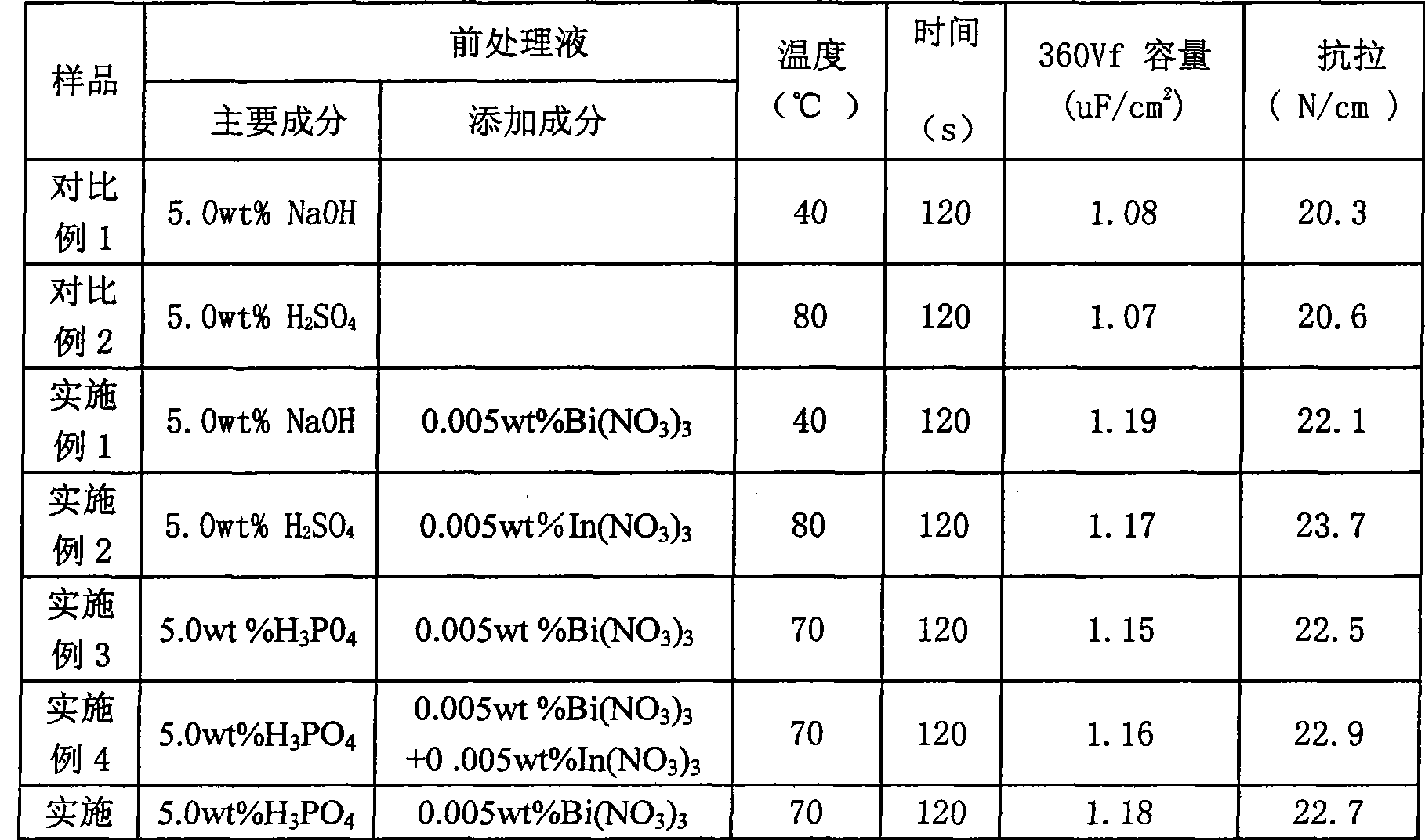

Examples

Embodiment 1

[0018] Example 1 is to place the aluminum foil at a temperature of 40°C, a concentration of 5.0% sodium hydroxide (NaOH) and 0.005% bismuth nitrate (Bi(NO 3 ) 3 ) in the pretreatment solution for 120 seconds, and then carry out the usual porosity corrosion, hole expansion corrosion and post-treatment.

Embodiment 2

[0019] Embodiment 2 is to place the aluminum foil at a temperature of 80°C and a concentration of 5.0% sulfuric acid (H 2 SO 4 ) and 0.005% indium nitrate (In(NO 3 ) 3 ) in the pretreatment solution for 120 seconds, and then carry out the usual porosity corrosion, hole expansion corrosion and post-treatment.

Embodiment 3

[0020] Embodiment 3 is that aluminum foil is placed in temperature and is 70 ℃, concentration 5.0% phosphoric acid (H 3 PO 4 ) and 0.005% bismuth nitrate (Bi(NO 3 ) 3 ) in the pretreatment solution for 120 seconds, and then carry out the usual porosity corrosion, hole expansion corrosion and post-treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com