Preparation method and application of flexible nickel-cobalt double hydroxide/metal organic framework/fabric electrode

A metal-organic framework and double hydroxide technology, which is applied in the direction of alkaline storage battery electrodes, battery electrodes, nickel storage batteries, etc., can solve the problems of shortening the charge transmission path and reducing electrochemical impedance, so as to improve specific capacitance and cycle life , Improve the specific capacitance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

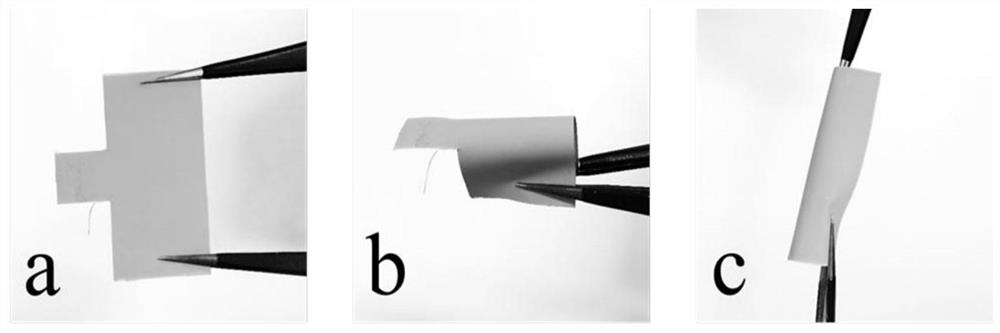

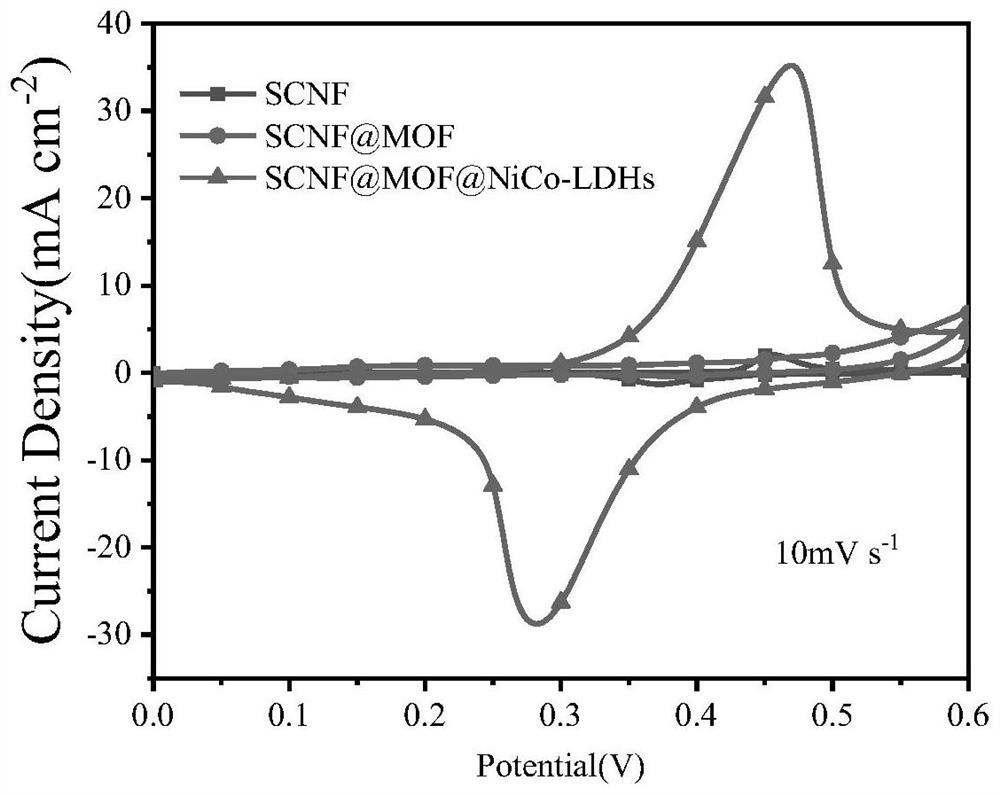

[0034] A method for preparing a flexible nickel-cobalt double hydroxide / metal organic framework / fabric electrode, the method comprising the following steps:

[0035] (1) Put the cut nickel-plated fabric (4*4cm) into a beaker filled with absolute ethanol, stir it ultrasonically for 10-30 minutes, and then dry it for later use;

[0036] (2) Weigh 0.43gCo(NO 3 ) 2 ·6H 2 O and 0.99g 2-methylimidazole were dissolved in 30mL deionized water respectively, and stirred evenly to form solution A;

[0037] (3) Put the fabric obtained in step (1) into the above-mentioned solution A, conduct a hydrothermal reaction at 20°C for 1 hour, take it out, wash and dry it, and obtain a metal organic framework / fabric;

[0038] (4) Weigh 0.17gNiSO 4 ·6H 2 O was dissolved in 40mL of deionized water, stirred evenly to obtain solution B, put the sample obtained in step (3) into the above solution B, and reacted hydrothermally at 20°C for 1.5 hours, took it out, washed and dried, and obtained nickel...

Embodiment 2

[0045] A method for preparing a flexible nickel-cobalt double hydroxide / metal organic framework / fabric electrode, the method comprising the following steps:

[0046] (1) Put the cut nickel-plated fabric (4*4cm) into a beaker filled with absolute ethanol, stir it ultrasonically for 10-30 minutes, and then dry it for later use;

[0047] (2) Weigh 0.43gCo(NO 3 ) 2 ·6H 2 O and 0.99g 2-methylimidazole were dissolved in 30mL deionized water respectively, and stirred evenly to form solution A;

[0048] (3) Put the fabric obtained in step (1) into the above-mentioned solution A, conduct a hydrothermal reaction at 20°C for 4 hours, take it out, wash and dry it, and obtain a metal organic framework / fabric;

[0049] (4) Weigh 0.17gNiSO 4 ·6H 2 O was dissolved in 40mL of deionized water, stirred evenly to obtain solution B, put the sample obtained in step (3) into the above solution B, and reacted hydrothermally at 20°C for 1.5 hours, took it out, washed and dried, and obtained nicke...

Embodiment 3

[0052] A method for preparing a flexible nickel-cobalt double hydroxide / metal organic framework / fabric electrode, the method comprising the following steps:

[0053] (1) Put the cut nickel-plated fabric (1*1cm) into a beaker filled with absolute ethanol, stir it ultrasonically for 10-30 minutes, and then dry it for later use;

[0054] (2) Weigh 0.43gCo(NO 3 ) 2 ·6H 2 O and 0.99g 2-methylimidazole were dissolved in 30mL deionized water respectively, and stirred evenly to form solution A;

[0055] (3) Put the fabric obtained in step (1) into the above-mentioned solution A, conduct a hydrothermal reaction at 10°C for 4 hours, take it out, wash and dry it, and obtain a metal organic framework / fabric;

[0056] (4) Weigh 0.17gNiSO 4 ·6H 2 O was dissolved in 40mL of deionized water, stirred evenly to obtain solution B, put the sample obtained in step (3) into the above solution B, and reacted hydrothermally at 20°C for 6 hours, took it out, washed and dried, and obtained nickel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com