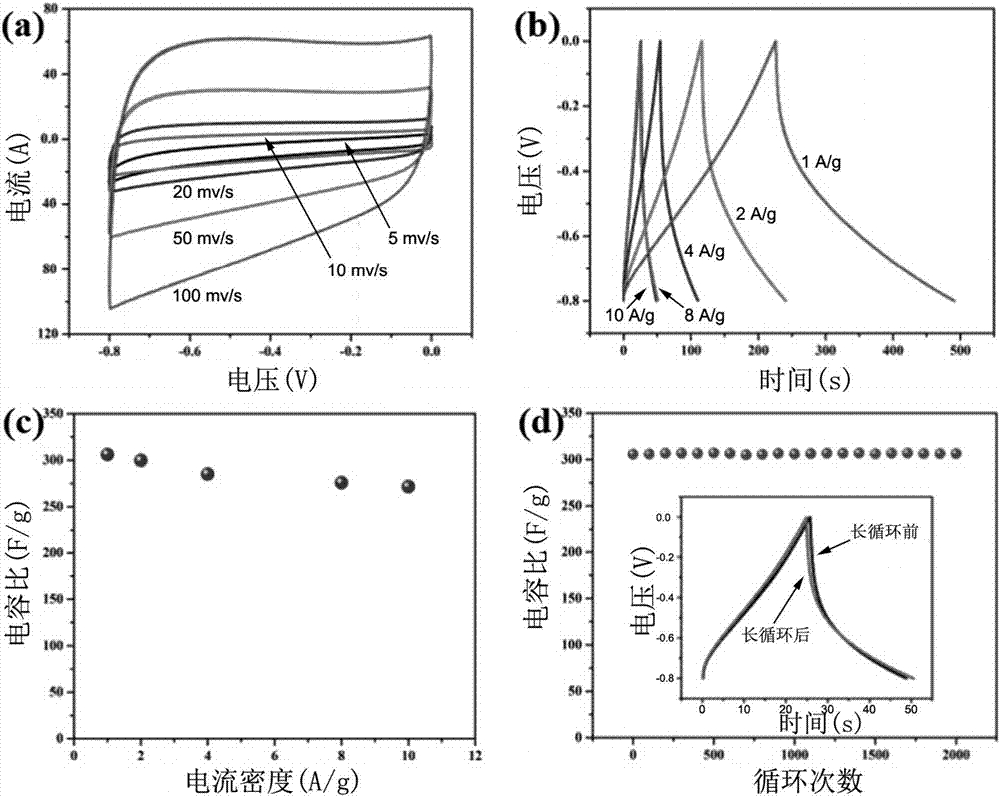

Hollow porous carbon ball electrode material for supercapacitors and method for preparing hollow porous carbon ball electrode material

A supercapacitor, hollow porous technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. The effect of specific capacitance, good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] In order to better understand the present invention, the present invention will be further described through specific examples below, but the protection scope of the present invention is not limited thereto.

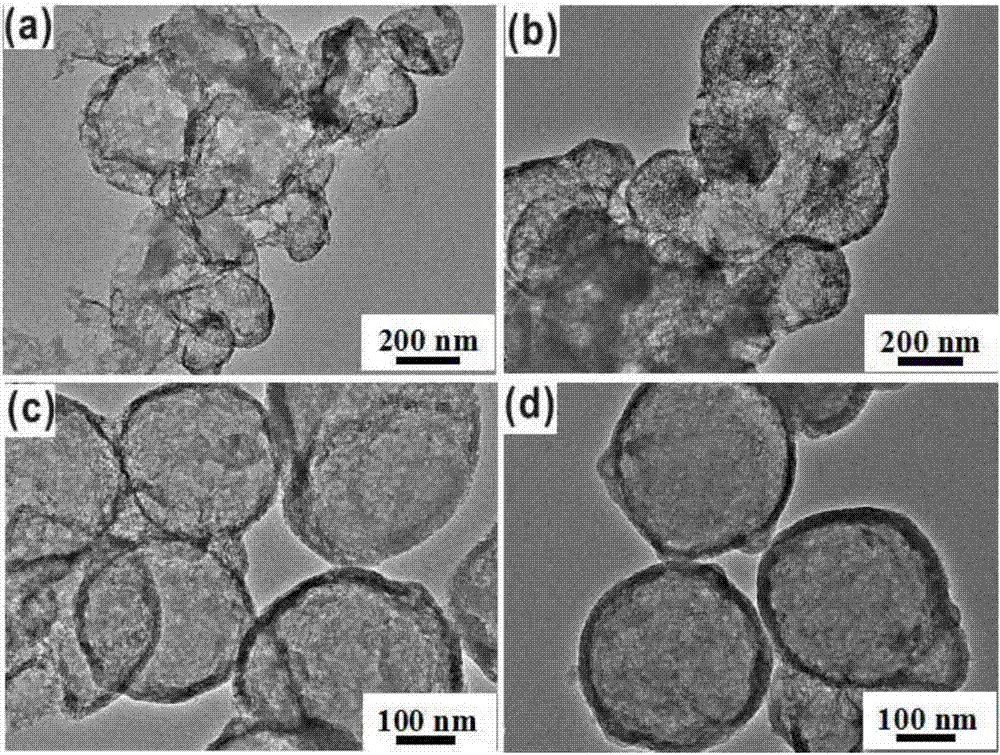

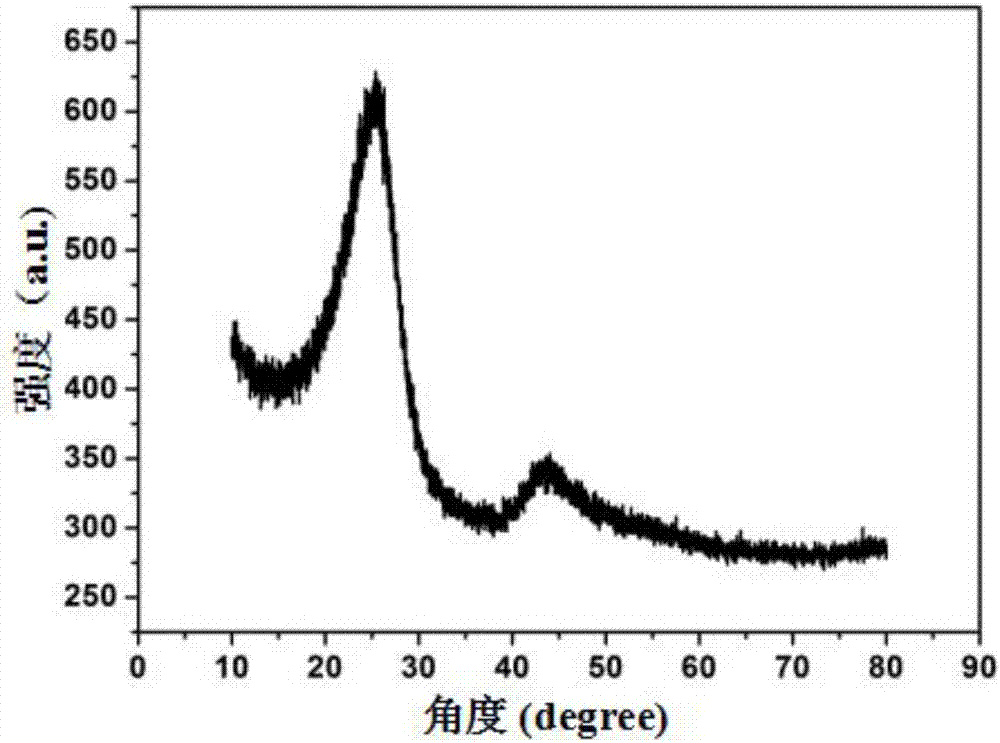

[0026] 1. Preparation of hollow porous carbon nanospheres

[0027] (1) Preparation of sulfonated polystyrene nanospheres

[0028] Take 2 g of polystyrene nanospheres with a diameter of about 200 nm and add them to 50 mL of concentrated sulfuric acid, stir and react for 2 hours at 40 ° C, centrifuge and wash to obtain polystyrene nanospheres with sulfonic acid groups on the surface. The product needs to be stored in ethanol for future use.

[0029] (2) Take 2 g of the prepared sulfonated polystyrene nanospheres and put them into a 50 mL centrifuge tube, and disperse evenly through ultrasonic to obtain a dispersion of sulfonated polystyrene nanospheres.

[0030] (3) Prepare FeCl with a molar concentration of 2mM respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com