Cobaltosic oxide/NiCoAl dual-layer hydroxide composite material and preparation method thereof

A technology of double-layer hydroxide and cobalt tetroxide, which is used in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of poor rate performance and unstable structure, and achieve improved conductivity, low cost and good ratio. The effect of capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

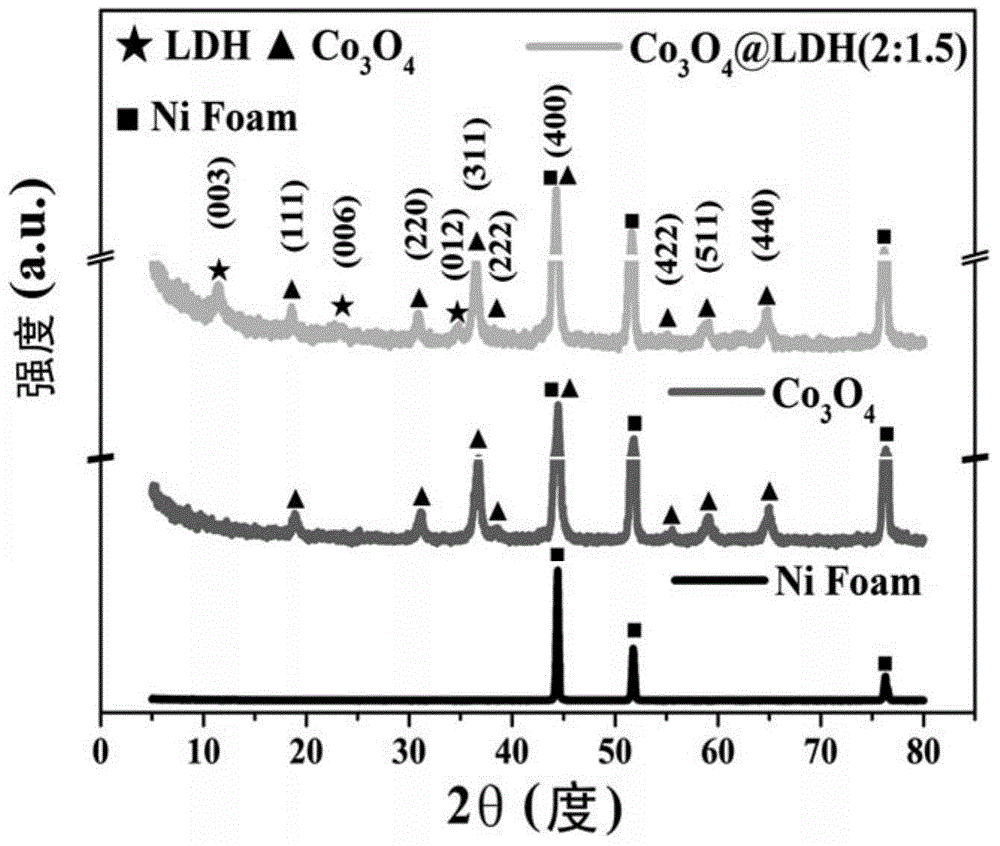

[0030] The preparation method of tricobalt tetroxide / NiCoAl double-layer hydroxide composite material provided by the invention comprises the following steps:

[0031] Step 1: Add cobalt nitrate hexahydrate, ammonium fluoride and urea to the deionized In deionized water, the first mixed system is obtained through thorough mixing;

[0032] Specifically, take cobalt nitrate hexahydrate, ammonium fluoride, and urea respectively, add them to deionized water, and control the molar ratio of cobalt nitrate hexahydrate, ammonium fluoride, urea, and deionized water to 1:3~4.5: 10~13:1400~1680 (such as 1:3.1:10.5:1410, 1:3.5:12:1550, 1:3.5:11:1500, 1:3.8:11.8:1580, 1:4:12.2:1600, 1 :4:10.2:1660, 1:3.2:12:1650, 1:4.2:12:1650, 1:4.2:13:1410, 1:4.2:13:1450, 1:4.2:13:1480, 1:4.2 :13:1520, 1:4.2:13:1670), stirred at room temperature to make it fully mixed, so as to obtain the first mixed system, preferably, the stirring time is 0.5 ~ 24h (such as 0.6h, 1h, 3h, 5h, 8h, 12h, 14h, 16h, 18h, ...

Embodiment 1

[0050] (1) Get 0.69g cobalt nitrate hexahydrate, 0.3g ammonium fluoride and 1.5g urea respectively, add to 60ml deionized water, that is, the molar ratio of cobalt nitrate hexahydrate, ammonium fluoride, urea and deionized water is 1: 3.42:10.5:1405, uniformly stirred at room temperature for 2 hours to form a transparent solution, and obtained the first mixed system;

[0051] (2) Add 50g of foamed nickel substrate (thickness is 1.6mm, surface density 350±25g / ㎡) to the first mixing system described in step (1), then put into the reactor and seal the reactor, at 150 Reaction for 6 hours under high temperature, obtained the first reaction product;

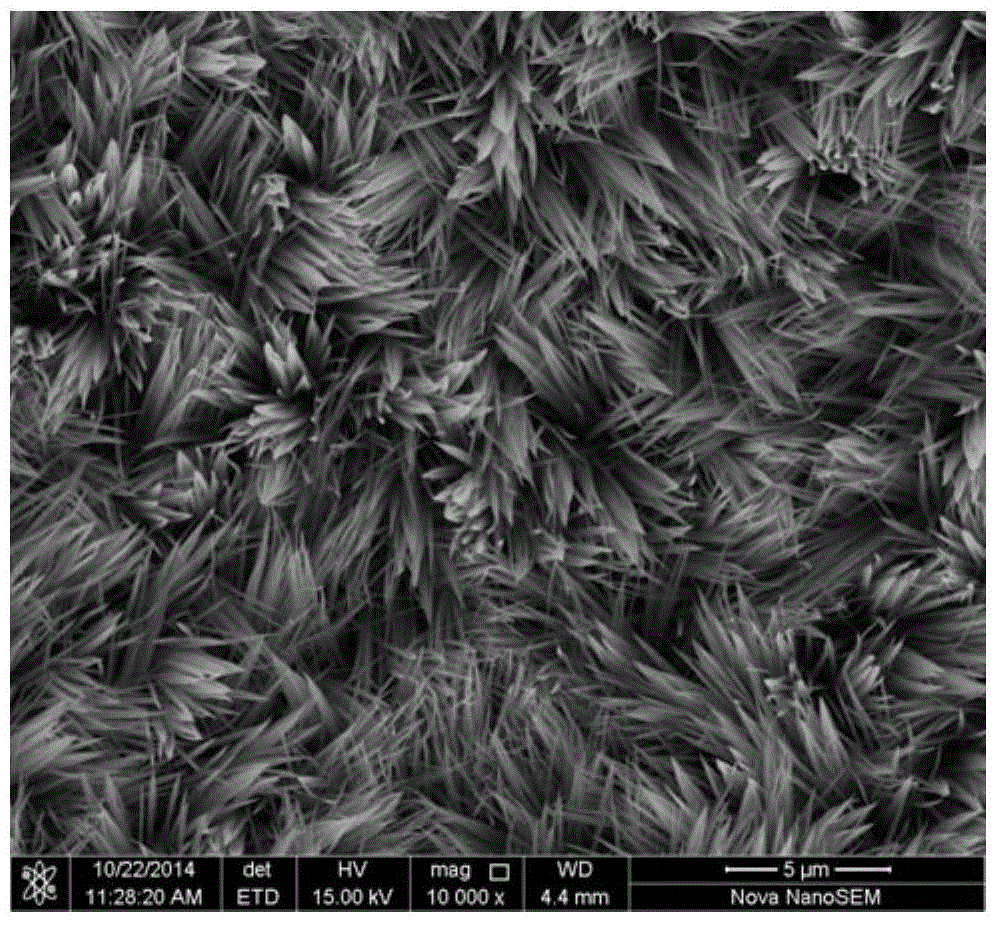

[0052] (3) The first reaction product described in step (2) is alternately washed with absolute ethanol and distilled water, each washed 3 times, and vacuum-dried at 80° C. for 15 hours, that is, an array of cobalt trioxide nanowires is obtained on the foamed nickel substrate;

[0053] (4) Take 0.28g cobalt nitrate hexahydrate, 0.28g...

Embodiment 2

[0059] (1) Get 0.69g cobalt nitrate hexahydrate, 0.3g ammonium fluoride and 1.5g urea respectively, add to 60ml deionized water, that is, the molar ratio of cobalt nitrate hexahydrate, ammonium fluoride, urea and deionized water is 1: 3.42:10.5:1405, uniformly stirred at room temperature for 2 hours to form a transparent solution, and obtained the first mixed system;

[0060] (2) Add 50g of foamed nickel substrate (thickness is 1.6mm, surface density 350±25g / ㎡) to the first mixing system described in step (1), then put into the reactor and seal the reactor, at 150 Reaction for 6 hours under high temperature, obtained the first reaction product;

[0061] (3) alternately washing the first reaction product described in step (2) with absolute ethanol and distilled water, each washing 3 times, and vacuum-drying at 80° C. for 15 hours to obtain the cobalt tetraoxide nanowire array;

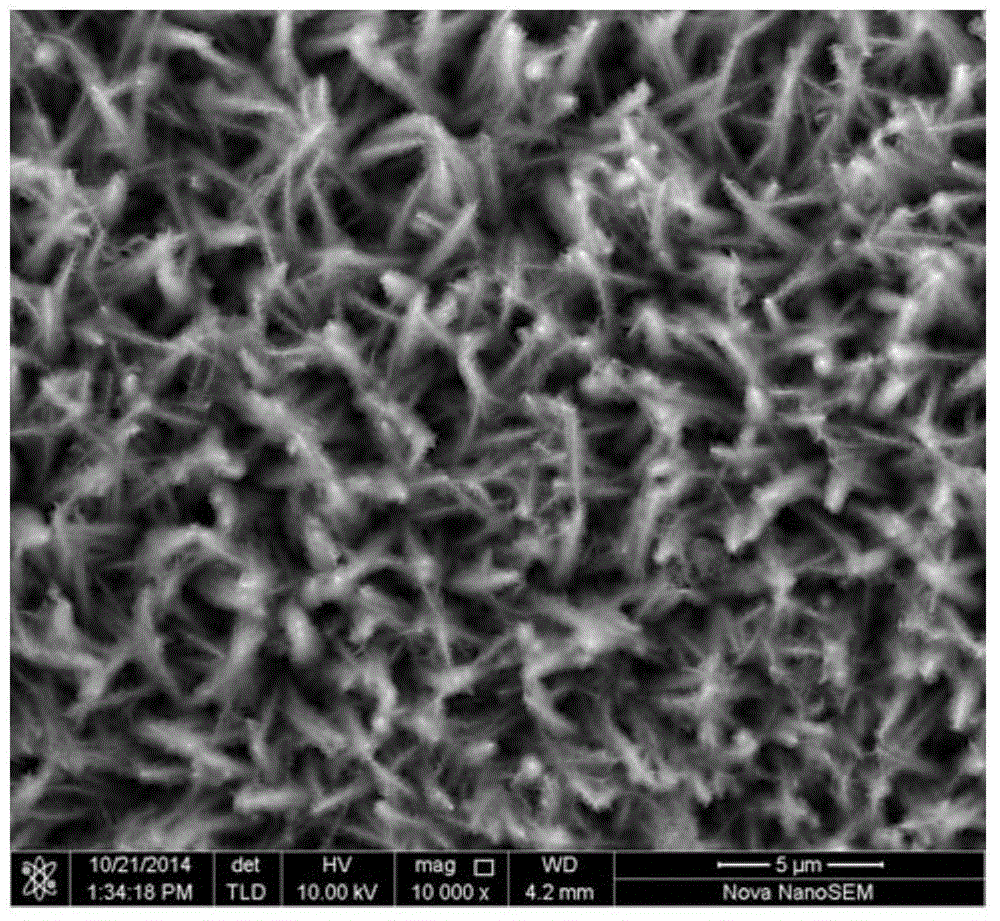

[0062] (4) Take 0.19g cobalt nitrate hexahydrate, 0.19g nickel nitrate hexahydrate, 0.07g aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com