Nano particle of Au/Ni12P5 nuclear shell structure and preparation method thereof

A nanoparticle, core-shell structure technology, applied in the field of metal-semiconductor composite nanomaterials, can solve the problems of demanding crystal structure, complex process and system, poor single crystallinity of the shell layer, etc., and achieve excellent capacitance performance and operation process Ease of operation and good size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

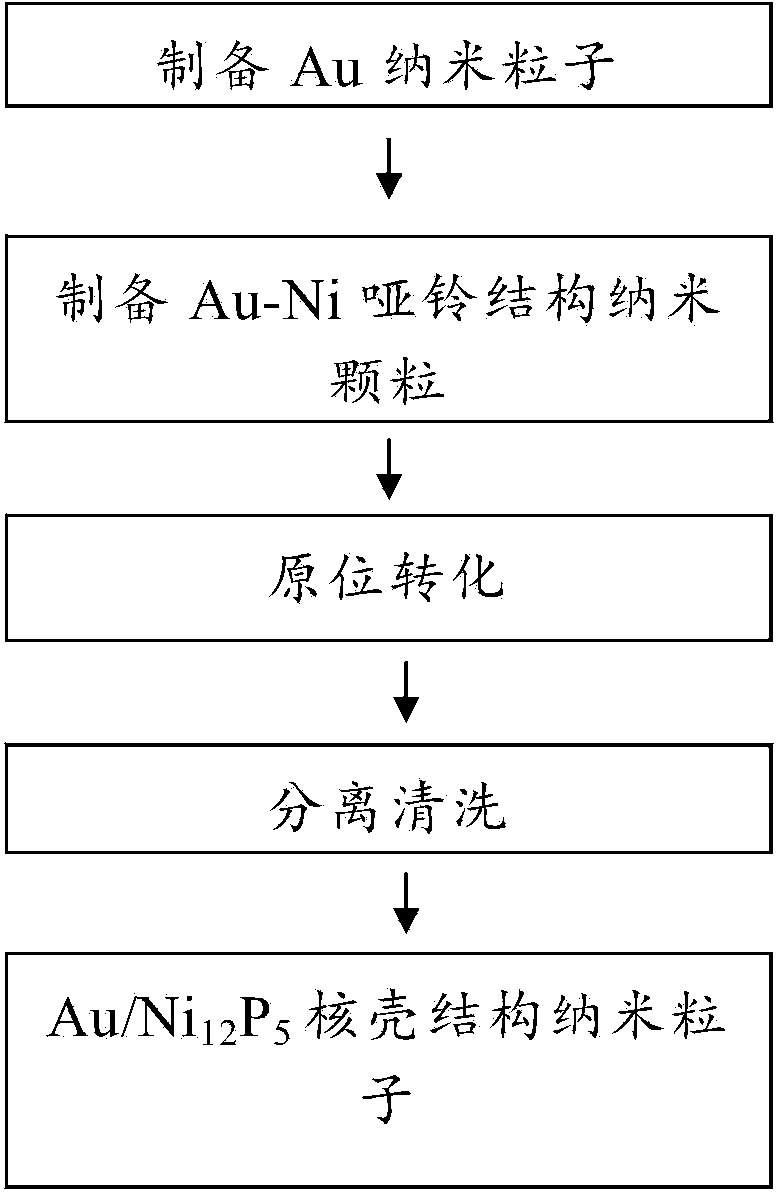

[0045] The present invention synthesizes Au / Ni 12 P 5 The method for nanoparticles of core-shell structure, preferably, the method comprises the following steps:

[0046] Step 1: Add 0.5g nickel acetylacetonate into 10ml oleylamine, heat up to 100°C, mix and stir until dissolved;

[0047] Step 2: Add the toluene solution of chloroauric acid (0.05g of chloroauric acid dissolved in 5ml of toluene) to the oleylamine solution in step 1, feed nitrogen gas (flow rate 60ml / min), and react at 100°C for 60min to obtain Oleylamine solution of nickel acetylacetonate containing Au nanoparticles;

[0048] Step 3: heating the oleylamine solution in step 2 to 230° C. for 60 minutes, and using oleylamine to reduce nickel acetylacetonate to obtain Au-Ni dumbbell-structured nanoparticles;

[0049] Step 4: Keep the heating temperature constant, add 1 g of triphenylphosphine to the oleylamine solution obtained in Step 3 to obtain Au-Ni dumbbell structure nanoparticles, and stir until dissolved...

Embodiment 2

[0072] The comparison of embodiment 2 capacitance performance

[0073] The Au-Ni of the multimer structure prepared by comparative example 1 12 P 5 Composite nanoparticles and the Au / Ni synthesized in Example 1 12 P 5 Nanoparticles with core-shell structure and pure Ni 12P 5 Specific capacitance performance of nanoparticles under the same test conditions. The specific test conditions are: a three-electrode electrochemical cell measurement system is used; the Au / Ni 12 P 5 Mix the core-shell structure nanoparticles with activated carbon and polytetrafluoroethylene in a mass ratio of 7:2:1 and spread it to 1cm 2 The nickel mesh was dried under vacuum at 60°C as the working electrode; the Hg / HgO electrode and the nickel mesh were used as the reference electrode and the counter electrode respectively; 2mol / l potassium hydroxide aqueous solution was used as the electrolyte.

[0074] The result is as Figure 6 shown. Figure 6 Ni with different composition structures under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com