NiCo2O4@NiCo2S4 core-shell nanowire array composite material and preparation method and application thereof

A nanowire array and composite material technology, applied in the field of nickel cobaltate@cobalt tetrasulfide core-shell nanowire array composite material and its preparation, can solve the problem of low energy density, poor cycle stability, super capacitor Popularization resistance and obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing nickel cobaltate@cobalt tetrasulfide alloyed nickel core-shell nanowire array composite material, comprising:

[0026] 1) nickel foam is carried out acidification;

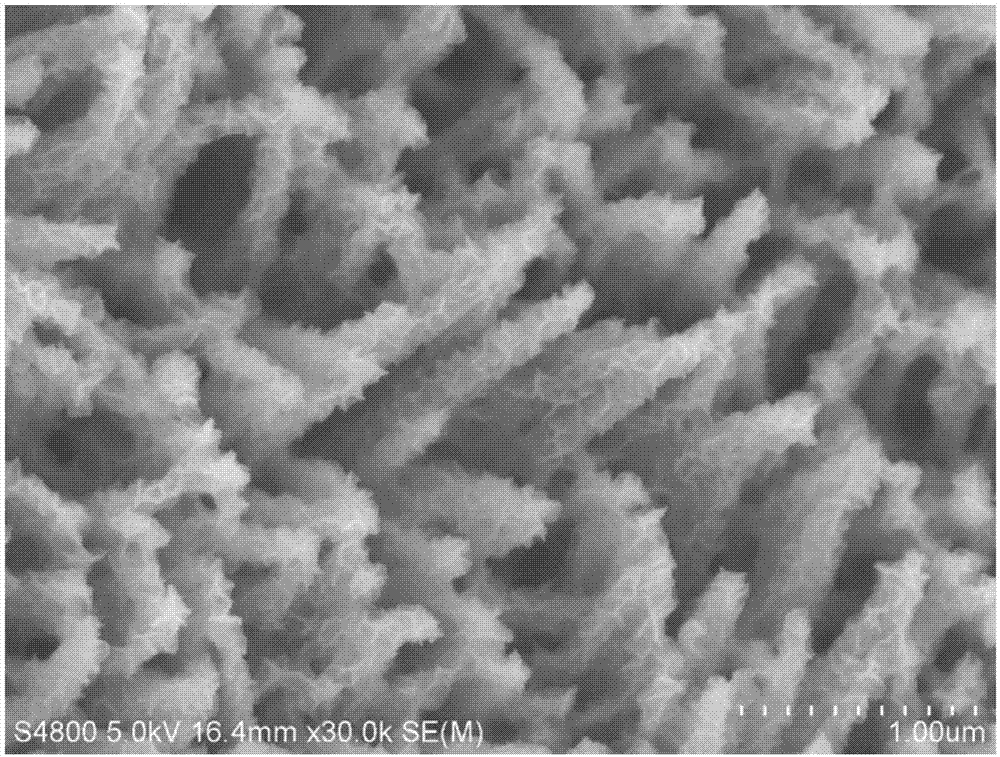

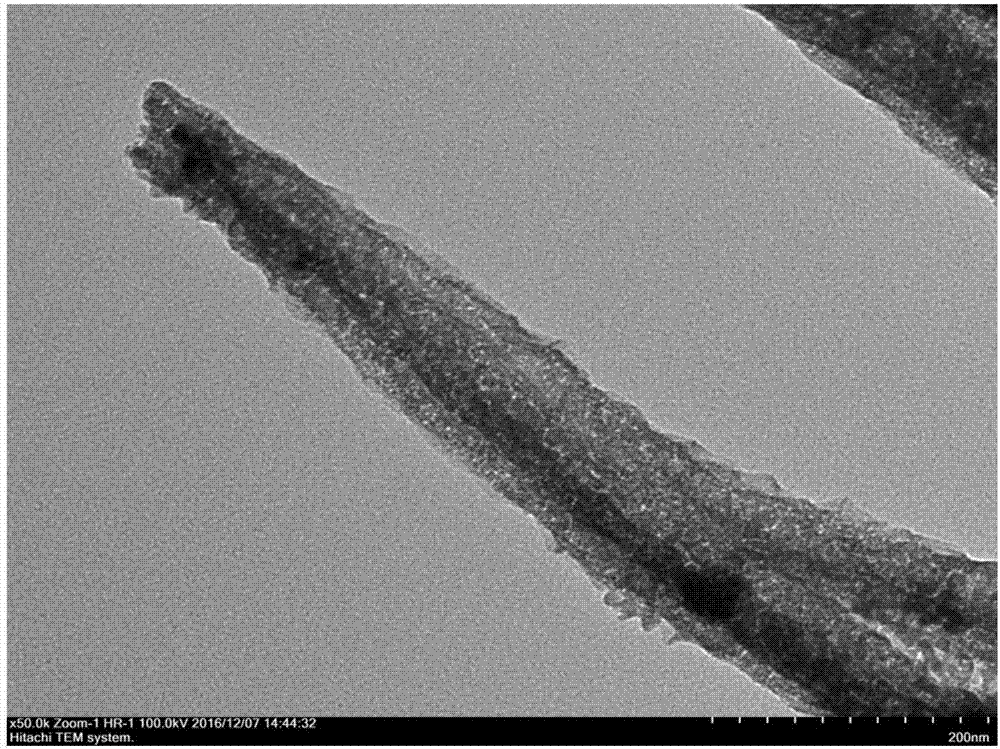

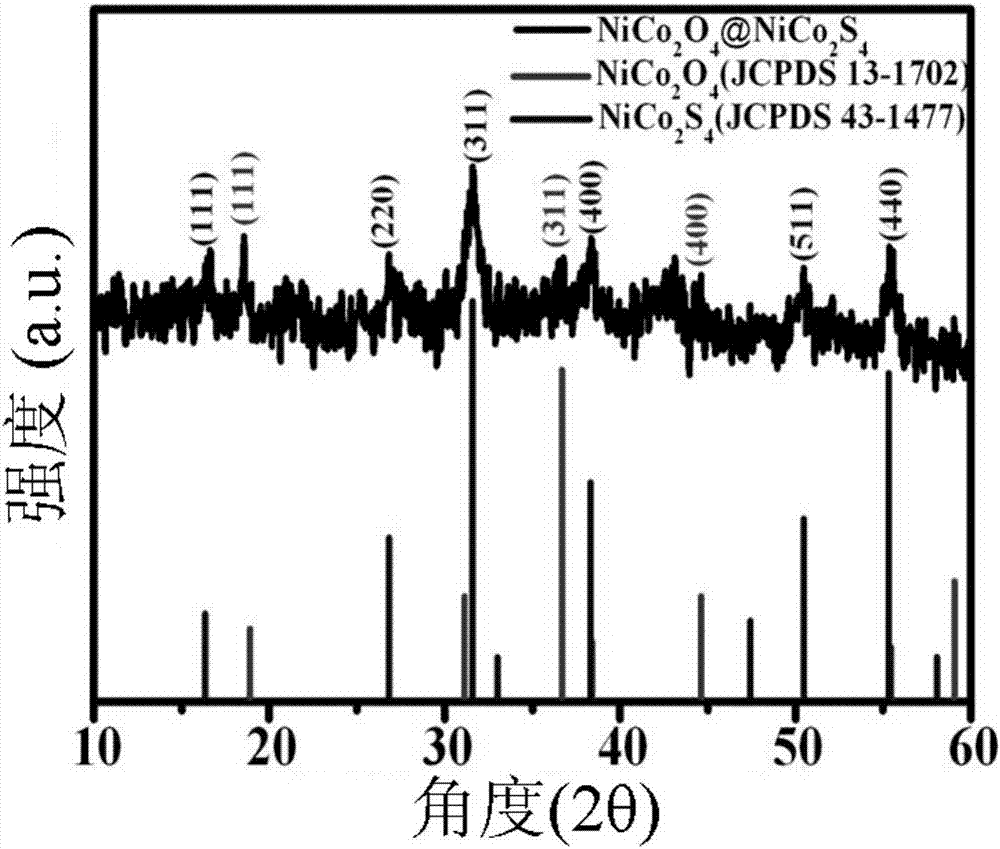

[0027] 2) Place the acidified nickel foam in the closed reaction solution for hydrothermal reaction, then wash and dry to obtain the Ni-Co composite precursor, then wash, dry and calcinate the Ni-Co composite precursor get NiCo 2 O4 nanowire array material;

[0028] 3) NiCo 2 O4 nanowire array material, sulfide and water undergo sulfuration reaction, and then the reaction product is washed and dried to obtain NiCo 2 o 4 @NiCo 2 S 4 Core-shell nanowire array composites;

[0029] Wherein, the reaction liquid contains nickel salt, cobalt salt, ammonium salt, urea and water.

[0030] In step 1) of the above-mentioned preparation method, acid treatment can be carried out in various ways, but in order to make the oxide on the surface of nickel foam removed mor...

Embodiment 1

[0051] 1) Pretreatment of foamed nickel: Soak foamed nickel (2cm x 2cm, 1.3mm in thickness, 0.1488g in weight) in 2mol / L hydrochloric acid solution for 20min and ultrasonically clean it with deionized water at 25°C. Wash for 10 minutes;

[0052] 2) Add 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 6mmol NH 4 F and 12mmol urea were dissolved in 35ml deionized water and stirred for 30min to form a mixed solution, then the nickel foam after the acidification treatment was immersed in the mixed solution, then the reaction system was transferred to a 50ml reactor and sealed for hydrothermal reaction (at 120°C React for 5h), take out the Ni-Co composite precursor after cooling, wash with deionized water and absolute ethanol three times respectively, dry at 60°C, and then calcinate at 320°C for 2h to obtain NiCo 2 o 4 nanowire array materials;

[0053] 3) Dissolve 0.8mmol sodium sulfide in 35ml deionized water, then add the above NiCo 2 o 4 The nanowire array mater...

Embodiment 2

[0055] Carry out NiCo according to the method for embodiment 1 2 o 4 @NiCo 2 S 4 Core-shell nanowire array composite material A2, the difference is: nickel foam meets the following conditions: the specification is 2cm × 3cm, the thickness is 1mm, and the weight is 0.148g; step 2) Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, NH 4 The contents of F and urea were 1mmol, 2mmol, 5mmol and 10mmol respectively; the content of sodium sulfide in step 3) was 0.8mmol, and the sulfidation reaction condition was 4h at 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com