Preparation method for cobalt sulfide/carbon composite material and product and application therefor

A technology of carbon composite materials and cobalt sulfide, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex and unfavorable crystal growth mechanisms, and great influence on the growth process, and achieve good cycle stability. The effect of high specific capacitance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of cobalt sulfide / carbon composites

[0033] S1. Under the action of ultrasonic dispersion, cobalt nitrate Co(NO 3 ) 2 and CS 2 mix evenly;

[0034] S2. Transfer the obtained homogeneous solution to a solvothermal reactor so that its volume is filled with 60% of the reactor volume, and the reactor is covered and tightened;

[0035] S3. Put the reaction kettle into a constant temperature oven, carry out solvothermal reaction at 180° C. for 20 hours, then cool to room temperature naturally, centrifuge the resulting mixture, collect the solid product, wash with absolute ethanol and distilled water three times respectively, The obtained solid product is vacuum-dried at 80°C to obtain a cobalt sulfide / carbon composite material.

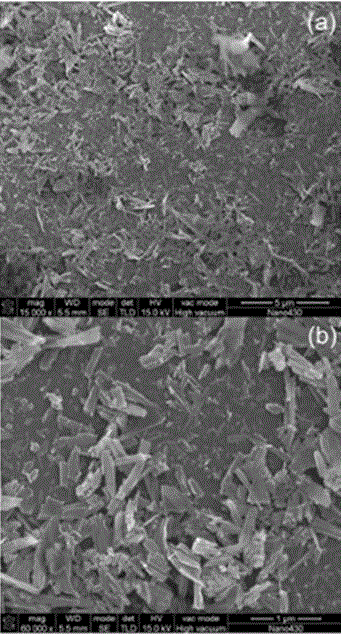

[0036] The apparent morphology of the prepared cobalt sulfide / carbon composite was observed by scanning electron microscopy, as shown in figure 1 shown. SEM photo ( figure 1 (a), (b)) show that the as-prepared cobalt sulfide / carbo...

Embodiment 2

[0044] Preparation of cobalt sulfide / carbon composites

[0045] S1. Under the action of ultrasonic dispersion, the Co(NO 3 ) 2 and CS 2 mix evenly;

[0046] S2. Transfer the obtained homogeneous solution to a solvothermal reactor so that its volume is filled with 60% of the reactor volume, and the reactor is covered and tightened;

[0047] S3. Put the reaction kettle into a constant temperature oven, perform solvothermal reaction at 220°C for 24 hours, then cool to room temperature naturally, centrifuge the resulting mixture, collect the solid product, wash with absolute ethanol and distilled water 3 times respectively, The obtained solid product is vacuum-dried at 80°C to obtain a cobalt sulfide / carbon composite material.

[0048] The apparent morphology of the prepared cobalt sulfide / carbon composite was observed by scanning electron microscopy, as shown in Figure 4 shown. Scanning electron micrographs show that the prepared cobalt sulfide / carbon composite material pr...

Embodiment 3

[0055] The preparation of the cobalt sulfide / carbon composite material of the present embodiment and the preparation of the supercapacitor electrode sheets are the same as in Example 1, the difference is that cobalt nitrate and carbon disulfide (CS 2 ) The ratio of the amount of substance is 1:1.2.

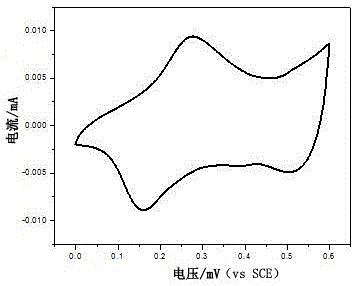

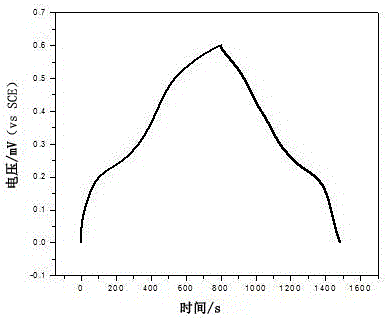

[0056] Electrochemical performance test

[0057] The electrode prepared above was assembled into a simulated supercapacitor unit in 6mol / L KOH solution for testing.

[0058] At a scanning speed of 5mV / s, the specific capacitance of the obtained cobalt sulfide / carbon composite was 220F / g. After 1000 cycles of charging and discharging, the specific capacitance value of the electrode can be maintained at 94% of the initial value, showing good cycle performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com