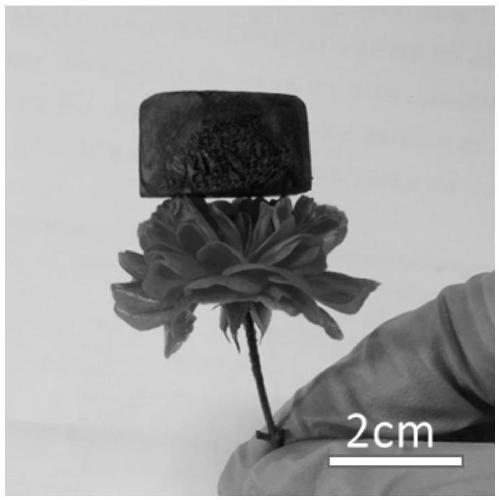

Two-dimensional transition metal carbide (nitride) aerogel as well as preparation method and application thereof

A transition metal, aerogel technology, applied in the direction of alkali metal compounds, nitrogen and non-metallic compounds, alkali metal oxides/hydroxides, etc. High specific surface area and other problems, to achieve good adsorption effect, good application prospects, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

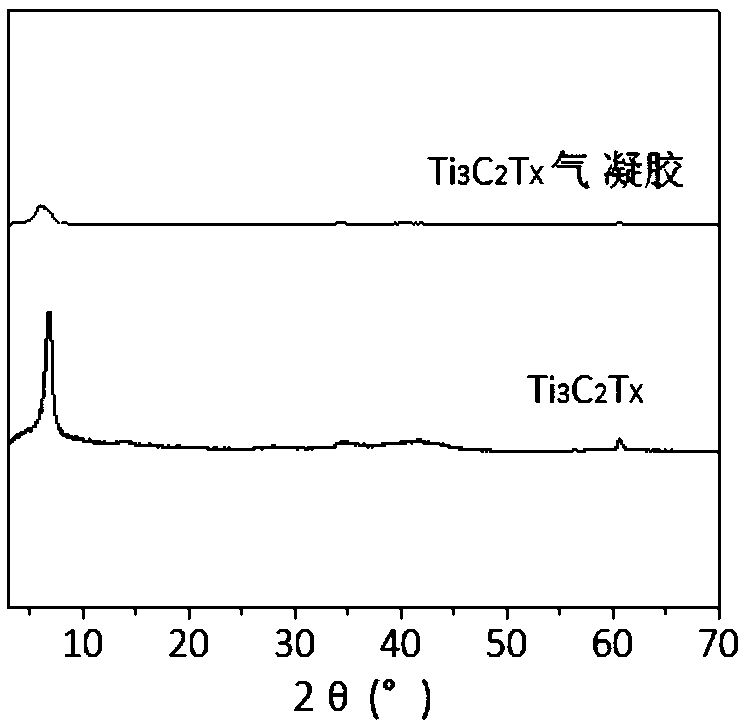

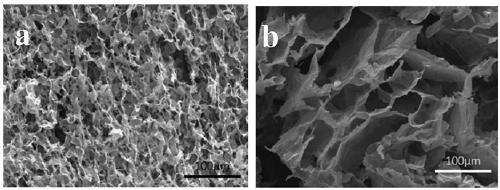

[0025] (1) Weigh 1g of lithium fluoride and add it to 20mL of 9M hydrochloric acid solution, stir for 20min to form a uniform solution, then slowly add 1g of ternary layered carbide Ti which has passed through a 200 mesh sieve3 AlC 2 Powder, heated in a water bath at 35°C, and stirred magnetically at 400r.p.m for 24h. Then use absolute ethanol and deionized water to alternately centrifuge and wash 6 times (rotating speed is 4000r.p.m, centrifuge 10min each time), until the supernatant pH=6.2, obtain multilayer Ti 3 C 2 T x . The resulting multilayer Ti 3 C 2 T x Disperse in 50mL deionized water, vortex for 20min, and centrifuge at 1500r.p.m for 1h to remove uncorroded Ti 3 AlC 2 and multilayer Ti 3 C 2 T x , take the above suspension and centrifuge at 4500r.p.m for 1h to obtain single or few layers of Ti 3 C 2 T x Nanosheet precipitation.

[0026] (2) Ti obtained in the above steps 3 C 2 T x The nanosheet precipitate was redispersed in water, and its concentra...

Embodiment 2

[0030] (1) Weigh 0.5g lithium fluoride and add it into 10mL 9M hydrochloric acid solution, stir for 20min to form a uniform solution, then put 0.5g of Ti 3 AlC 2 The powder was slowly added into the lithium fluoride hydrochloride solution, heated in a water bath at 40°C, and stirred by magnetic force at 400r.p.m for 20h. Then use absolute ethanol and deionized water to alternately centrifuge and wash 6 times (rotating speed is 4000r.p.m, centrifuge 10min each time), until the supernatant pH=6.5, obtain multilayer Ti 3 C 2 T x . The resulting multilayer Ti 3 C 2 T x Disperse in 25mL deionized water, vortex for 10min, and centrifuge at 1500r.p.m for 2h to remove uncorroded Ti 3 AlC 2 and multilayer Ti 3 C 2 T x , take the above suspension and centrifuge at 3500r.p.m for 2h to obtain single or few layers of Ti 3 C 2 T x Nanosheet precipitation.

[0031] (2) Ti obtained in the above steps 3 C 2 T x The nanosheet precipitate was redispersed in water, and its conce...

Embodiment 3

[0035] (1) Weigh 1g of lithium fluoride and add it to 20mL of 9M hydrochloric acid solution, stir for 20min to form a uniform solution, then slowly add 1g of ternary layered carbide Ti which has passed through a 200 mesh sieve 3 AlC 2 Powder, heated in a water bath at 30°C, and stirred with magnetic force at 300r.p.m for 48h. Then use absolute ethanol and deionized water to alternately centrifuge and wash 6 times (rotating speed is 5000r.p.m, centrifuge 5min each time), until the supernatant pH=6.4, obtain multilayer Ti 3 C 2 T x . Disperse the obtained multilayer in 100mL deionized water, shake it by hand for 60min, and centrifuge at 1500r.p.m for 1h to remove uncorroded Ti 3 AlC 2 and multilayer Ti 3 C 2 T x , take the above suspension and centrifuge it at 3500r.p.m for 1h to obtain monolayer or few layers of Ti 3 C 2 T x Nanosheet precipitation.

[0036] (2) Ti obtained in the above steps 3 C 2 T x The nanosheet precipitate was redispersed in water, and its c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com