Application of macroporous adsorption resin to cigarettes

A technology of pore adsorption and resin, which is applied in the field of cigarette harm reduction additive materials, can solve the problems of high cost, complicated material preparation process, and not being widely used, and achieve the effect of improving adsorption rate and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare the oil phase first, the composition is 6ml styrene, 2ml divinylbenzene, 5ml toluene, 0.2g benzoyl peroxide BPO, and then configure the water phase, the composition is 80 ml water, 0.5g sodium chloride and 2 g polyethylene alcohol. Under stirring, the water phase was added into the oil phase, then the temperature was raised to 80° C., and the reaction was carried out for 12 hours. The obtained spherical product was extracted with ethanol for 24 hours to obtain the macroporous adsorption resin 1.

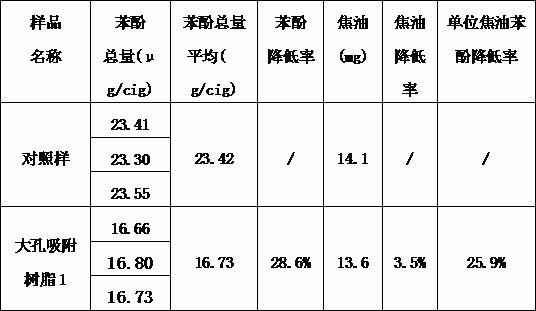

[0024] It is used as a composite filter additive with an additive amount of 15 mg / cig. Taking the cigarette without adding any filter modified material as a control sample, the cigarette smoking test is carried out on a smoking machine according to the standard smoking conditions, and according to the standard YC / T255-2008 for the detection of phenol release. Three parallel samples were taken for each sample, and the results are shown in Table 1.

[0025] Table 1 R...

Embodiment 2

[0030] Prepare the oil phase first, the composition is 6ml styrene, 4ml divinylbenzene, 10ml xylene, 0.2g azobisisobutylcyanide, and then configure the water phase, the composition is 80 ml water, 0.5g calcium chloride and 2 g gelatin . Under stirring, the water phase was added into the oil phase, then the temperature was raised to 80° C., and the reaction was carried out for 12 hours. The obtained spherical product was extracted with ethanol for 24 hours to obtain the macroporous adsorption resin 2.

[0031] It is used as a composite filter additive with an additive amount of 15 mg / cig. Taking the cigarette without adding any filter modified material as a control sample, the cigarette smoking test is carried out on a smoking machine according to the standard smoking conditions, and according to the standard YC / T255-2008 for the detection of phenol release. Each sample has three parallel samples, and the results are shown in Table 2.

[0032] Table 2 Macroporous Adsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com