Preparation method of high-purity AlON transparent ceramic powder

A technology of transparent ceramics and powders, which is applied in the field of preparation of high-purity γ-AlON transparent ceramic powders, can solve problems such as difficulty in ensuring consistency, slow research progress, and low maturity of process technology, so as to reduce preparation costs and improve Composition uniformity and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

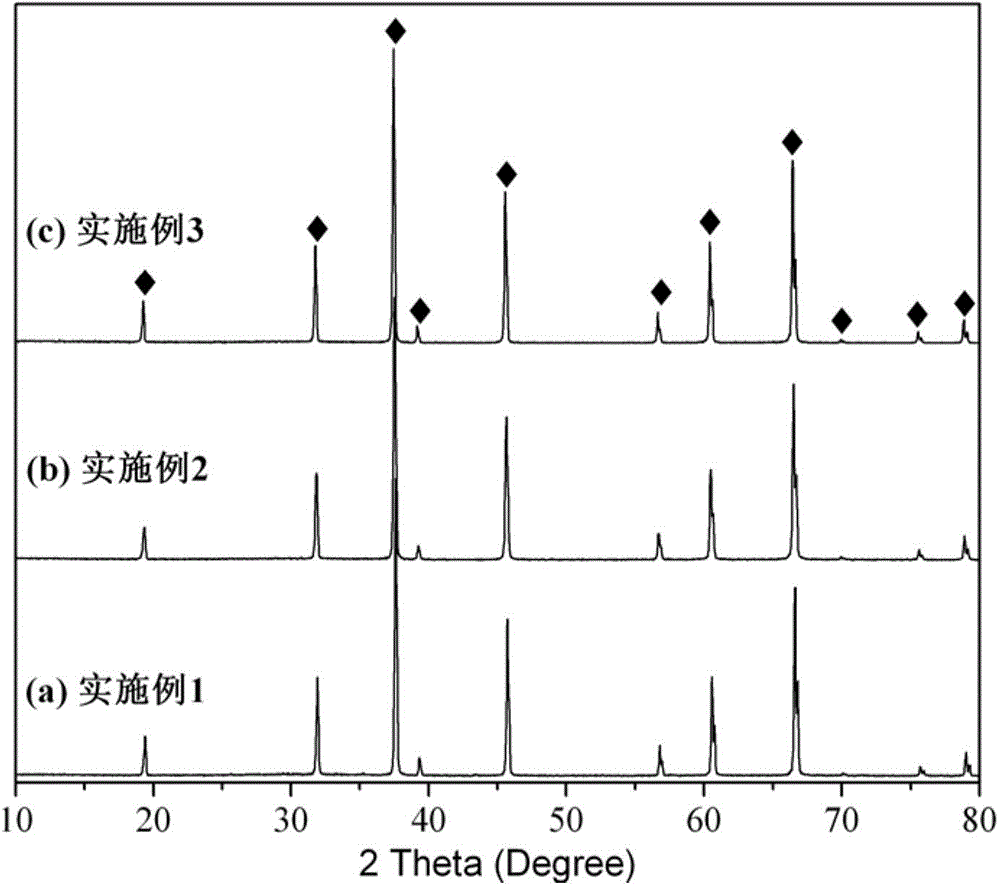

Examples

preparation example Construction

[0043] A kind of preparation method of high-purity AlON transparent ceramic powder of the present invention comprises the following steps:

[0044] (1) Weighing of raw materials:

[0045] With C, Al 2 O is the raw material, according to the mass percentage: C content 4.5-6.5wt%, γ-Al 2 o 3 The content is 93.5~95.5wt%, the raw materials are weighed separately, and set aside;

[0046] The raw material C is active C powder, the purity is ≥99.75%, and the particle size is 10-100nm. Al mentioned in the raw material 2 o 3 For the following materials: γ-Al 2 o 3 Powder or γ-Al 2 o 3 Powder precursor; using γ-Al 2 o 3 When the precursor of powder, step (1) weighs the raw material and step (2) when preparing the premix liquid according to the Al in the precursor 2 o 3 Nominal content calculation.

[0047] (2) Premix preparation:

[0048] Add the raw materials in step (1) into pure water respectively, and disperse by one of the following methods: magnetic stirring, roller...

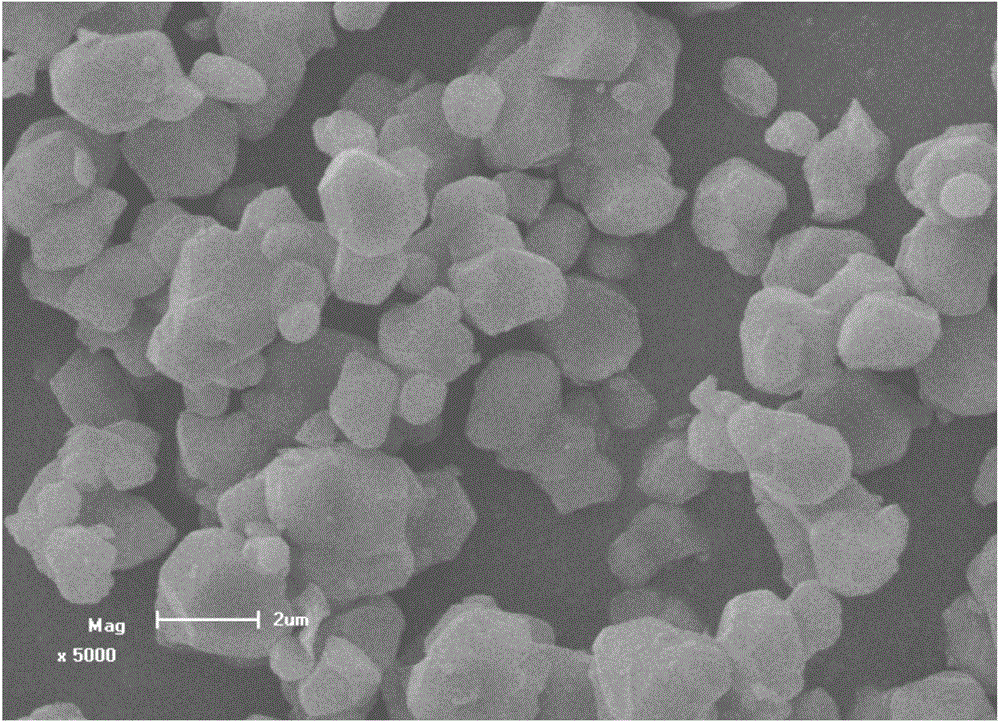

Embodiment 1

[0061] 1) Weigh the raw materials. According to the mass fraction ratio C:Al 2 o 3 =4.5wt%: 95.5wt%, take by weighing respectively C powder (purity 99.75%, average particle diameter is 20nm) 2.70g, γ-Al 2 o 3 Powder (purity 99.99%, average particle size is 50nm) 57.30g, standby;

[0062] 2) Premix preparation. a) Weigh 24.30g of pure water, add 0.14g of polyethylene glycol (PEG for short, molecular weight 6000) as a dispersant, then add the spare C powder in step 1), and stir magnetically at a rate of 500r / m for 6h , to obtain C suspension (the solid content of the powder is 10wt%, and the dispersing dose is 5wt% of the powder mass), for subsequent use; b) take by weighing 515.70g of pure water, add 0.29g of polyethylene glycol (abbreviated as PEG in English, molecular weight 6000) is a dispersant, and then the standby γ-Al in step 1) 2 o 3 Powder was added, and magnetically stirred at a rate of 500r / m for 6h to obtain γ-Al 2 o 3 Suspension (the solid content of the p...

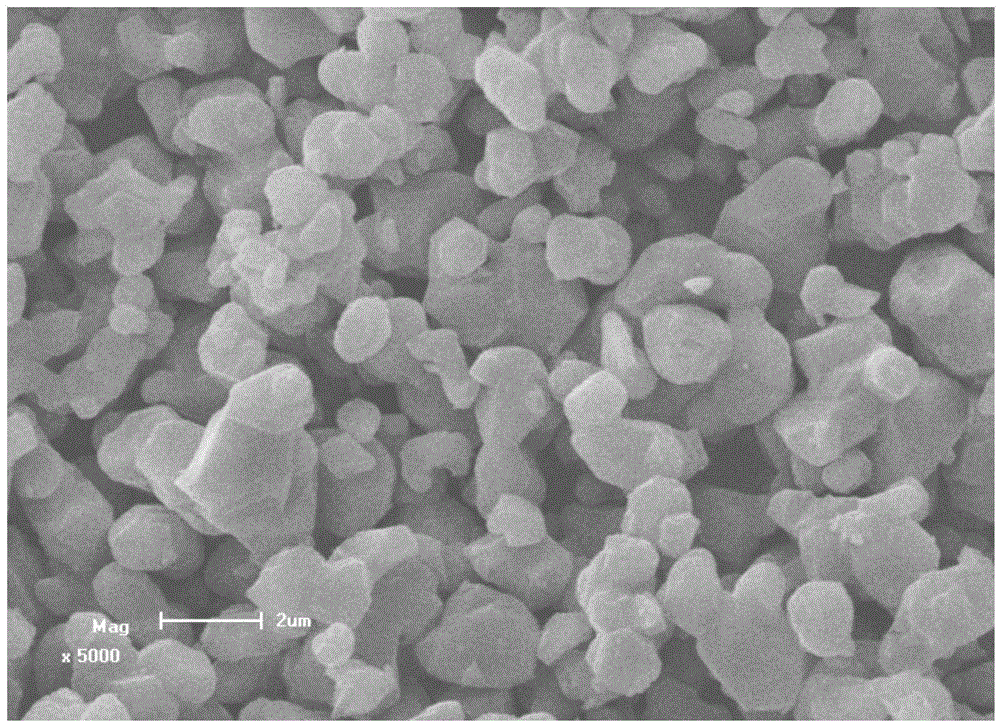

Embodiment 2

[0068]1) Weigh the raw materials. According to the mass fraction ratio C:Al 2 o 3 =5.5wt%: 94.5wt%, take by weighing respectively C powder (purity 99.8%, average particle diameter is 50nm) 3.85g, γ-Al 2 o 3 Powder (purity 99.99%, average particle size is 50nm) 66.15g, standby;

[0069] 2) Premix preparation. a) Weigh 44.28g of pure water, add 0.13g of polyethylene glycol (PEG for short, molecular weight 6000) as a dispersant, add the spare C powder in step 1), and stir magnetically at a rate of 800r / m for 2h, Then put it on the roller ball mill, use wear-resistant zirconia as the grinding ball, the mass ratio of ball and powder is 5:1, mix ball milling with 70r / min for 20h, get C suspension (powder solid content is 8wt%, dispersing dose 3.5wt% of the powder mass), standby; b) take 712.08g of pure water, add 0.66g of polyethylene glycol (abbreviated as PEG in English, molecular weight 6000) as a dispersant, and then use the standby γ in step 1) -Al 2 o 3 Add the powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com