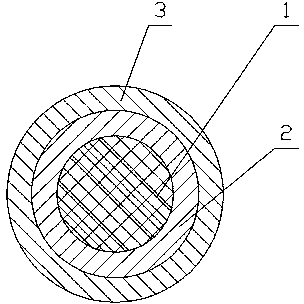

Coaxial three-layer high-activity bio-enzyme-embedded electrostatic spinning nano-fiber membrane and preparation method thereof

A nanofiber membrane and electrospinning technology, which is applied in spinning solution preparation, fiber treatment, rayon manufacturing, etc., can solve the problems of low enzyme reusability, limited enzyme load, poor contact between enzyme and substrate, etc. Achieve the effects of improving catalytic efficiency and reusability, promoting full contact, and reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Disperse 1.0 g of polyvinyl alcohol particles into 9 ml of deionized water, stir magnetically for 1 h at room temperature until fully swollen; the temperature rises to 70 °C, continue to stir until the solution is clear and transparent, slowly add 0.01 g of KCl to the above solution, stir magnetically to complete dissolution;

[0024] b. Dissolve 0.2 mg of active peroxidase in 0.5 ml of phosphate buffer solution with a pH value of 7.0, shake until it is completely dissolved to obtain a peroxidase dispersion; add the above peroxidase dispersion to 12 ml In the polyvinyl alcohol solution with a concentration of 11% (wt), shake well to uniformly disperse, and store at 4 °C for later use;

[0025] c. Dissolve 1.0 g of polystyrene particles in 9 ml of tetrahydrofuran solvent, and stir magnetically for 1 h at room temperature to form a homogeneous, stable and viscous sol;

[0026] d. The solution obtained in steps a to c is poured into a three-nozzle coaxial electrospinni...

Embodiment 2

[0029] a. Disperse 1.0 g of polyacrylic acid particles into 6 ml of deionized water, stir magnetically for 1 h at room temperature until fully swollen, raise the temperature to 70 °C, continue to stir until the solution is clear and transparent, slowly add 0.01 g of CaCl to the above solution 2 , magnetic stirring until completely dissolved;

[0030] b. Dissolve 0.2 mg of active lipase in 0.5 ml of a phosphate buffer solution with a pH value of 7.0, shake and shake until it is completely dissolved to obtain a lipase dispersion; add the above lipase dispersion to 10 ml with a concentration of 10% (wt ) in the polyvinyl acid solution, shake well until uniformly dispersed, and store at 4°C for later use;

[0031] c. Dissolve 1.0 g of polymethyl methacrylate particles in 3.5 ml of tetrahydrofuran solvent, and stir magnetically for 1 h at room temperature to form a homogeneous, stable and viscous sol;

[0032] d. The solution obtained in steps a to c is poured into the three-nozzl...

Embodiment 3

[0035] a. Disperse 1.0 g of polyacrylamide particles into 19 ml of deionized water, stir magnetically at room temperature for 1 hour until the solution is clear and transparent, slowly add 0.2 g of ethylenediaminetetraacetic acid (EDTA) to the above solution, and stir magnetically until completely dissolved;

[0036] b. Dissolve 0.2 mg of active urease in 0.6 ml of phosphate buffer solution with a pH value of 7.0, oscillate until completely dissolved to obtain a urease dispersion, add the above urease dispersion to 10ml with a concentration of 10% (wt ) in polyacrylamide solution, shake well until evenly dispersed, and store at 4°C until use;

[0037] c. Dissolve 1.0 g of polyacrylonitrile particles in 12 ml of dimethylformamide solvent, and stir magnetically at room temperature for 1 hour until a uniform, stable, and viscous sol is formed;

[0038] d. Pouring the solutions obtained in steps a to c into the three-nozzle coaxial electrospinning device respectively, using the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com