Floating type light self-cleaning microorganism immobilization membrane for removing oil contamination polluting water and preparation method of membrane

A microbial and floating technology, which is applied in the field of floating optical self-cleaning microbial immobilized membranes and preparations for removing oil from water bodies, can solve problems such as difficult recycling and increased costs, and achieve improved catalytic activity, reduced treatment costs, and higher recycling rates. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Disperse 1.0 g of polyvinylpyrrolidone particles into 4.0 ml of deionized water, stir magnetically at room temperature for 2 h until completely dissolved, and obtain a solution of polyvinylpyrrolidone with a concentration of 20% by mass; alcalophilus) strain SG bacterial liquid was added to 12 ml polyvinylpyrrolidone solution, oscillated and shaken until evenly dispersed to obtain a mixed solution of SG-polyvinylpyrrolidone;

[0024] b. Dissolve 1.0 g of polyvinylidene fluoride particles in 9 ml of N-methylpyrrolidone solvent, and stir magnetically for 2 h at room temperature to form a uniform, stable, and viscous sol;

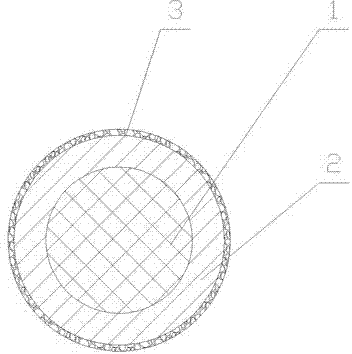

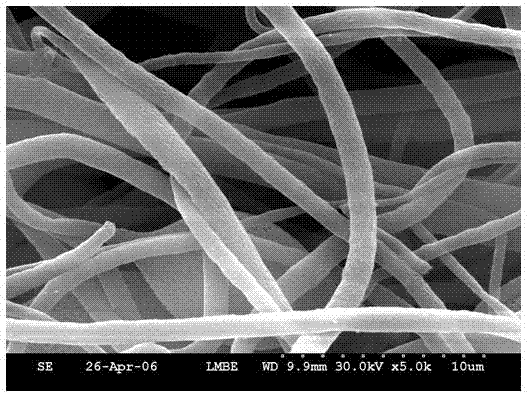

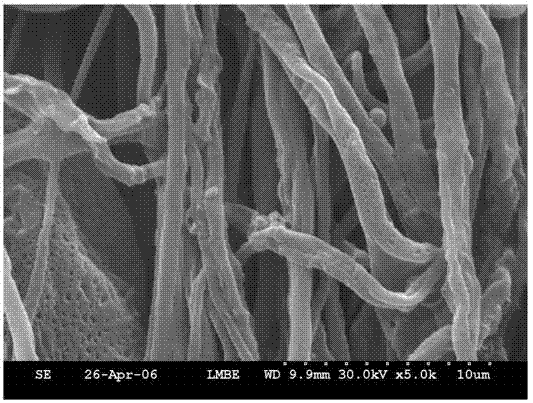

[0025] c. Fill the solutions in steps a and b into two nozzle coaxial electrospinning devices respectively, use the solution obtained in step a as the inner core, and the solution obtained in step b as the outer layer, and connect the positive and negative electrodes of the high-voltage power supply to stainless steel nozzles and aluminum foil, stainl...

Embodiment 2

[0029] a. Disperse 1.0 g of polyvinyl alcohol particles into 9 ml of deionized water, stir magnetically at room temperature for 1 h to fully swell, raise the temperature to 70°C, and continue stirring until the solution is clear and transparent to obtain a polyvinyl alcohol solution with a concentration of 10%. ; Then add 0.5 ml of Flavobacterium sp bacteria liquid to 10 ml of the prepared polyvinyl alcohol solution, shake well until evenly dispersed;

[0030] b. Dissolve 1.0 g polystyrene particles in 3.5 ml tetrahydrofuran solvent, and stir magnetically for 1 h at room temperature

[0031] Form a uniform, stable and viscous sol solution;

[0032] c. Fill the solutions in steps a and b into two nozzle coaxial electrospinning devices respectively, use the solution obtained in step a as the inner core, and the solution obtained in step b as the outer layer, and connect the positive and negative electrodes of the high-voltage power supply to stainless steel nozzles and aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com