Photo-thermal power generation system comprising diagrid industrial structure

A technology for solar thermal power generation and power generation system, which is applied in solar thermal power generation, machines/engines, mechanisms that generate mechanical power, etc. Corrosion resistance, small amount of concrete, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

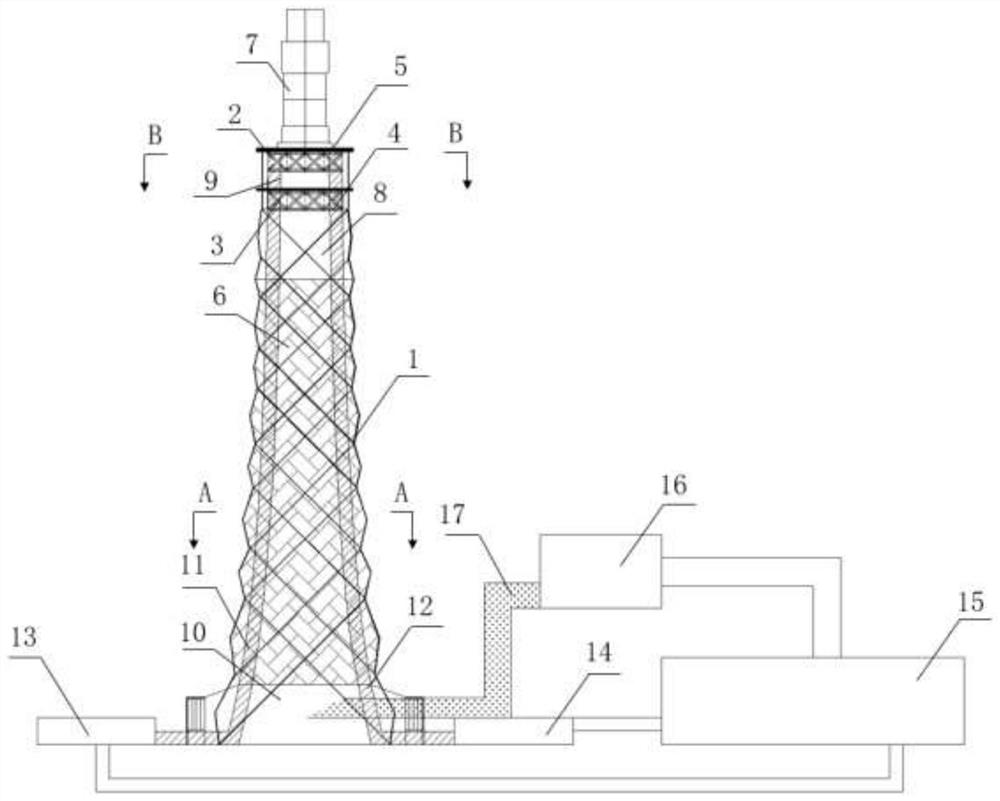

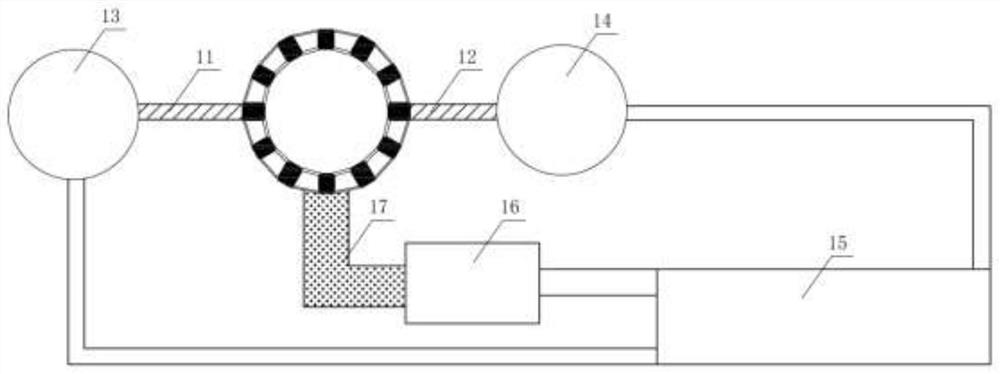

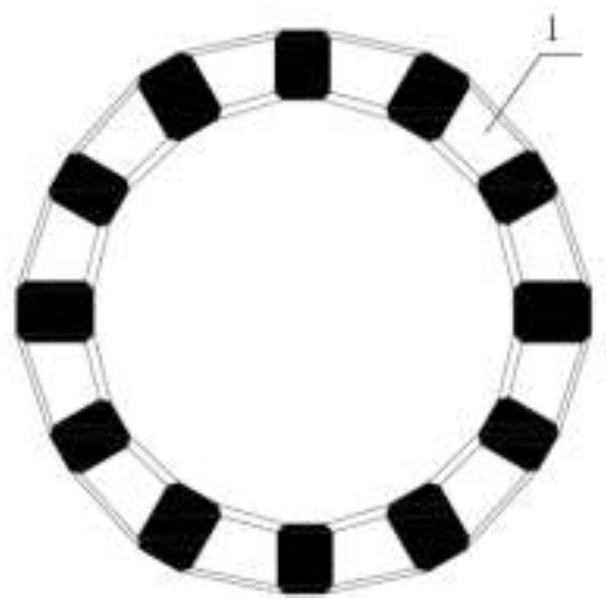

[0036] See figure 1 , figure 2 , image 3 and Figure 4 , Only as an example.

[0037] like Figure 1 ~ 2 As shown, a photothermal power generating system comprising a beverse grid industrial structure comprising a bevel meter industrial structure, a hot melt salt pipe (11), cold melted salt pipe (12), cold melted salt pipe (11) ), Hot melt salt tank (13), cold melted salt tank (14), steam turbine (15), steam generator (16), and other connecting pipes, etc. The hot-melt salt tube (11) and cold-melt salt pipe (12) inside industrial structures, and is connected to hot melt salt tanks (13) and cold melted salt tanks (14) exterior with oblique mesh industrial structures. The salt tank (13) is connected to the steam generator (15) through a hot salt pump, and the steam generator (15) is connected to the steam turbine (16) through the pipe, and the steam turbine (16) is re-formed by the steam pipe and the oblique mesh industrial structure. connect.

[0038]The structure is used as a light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com