A device and method for merging cable core wires

A technology of cable core and core wire, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of inconsistent coiling of core wire, broken wire, etc., to ensure manufacturing quality, prevent deviation and slip, and improve transmission. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

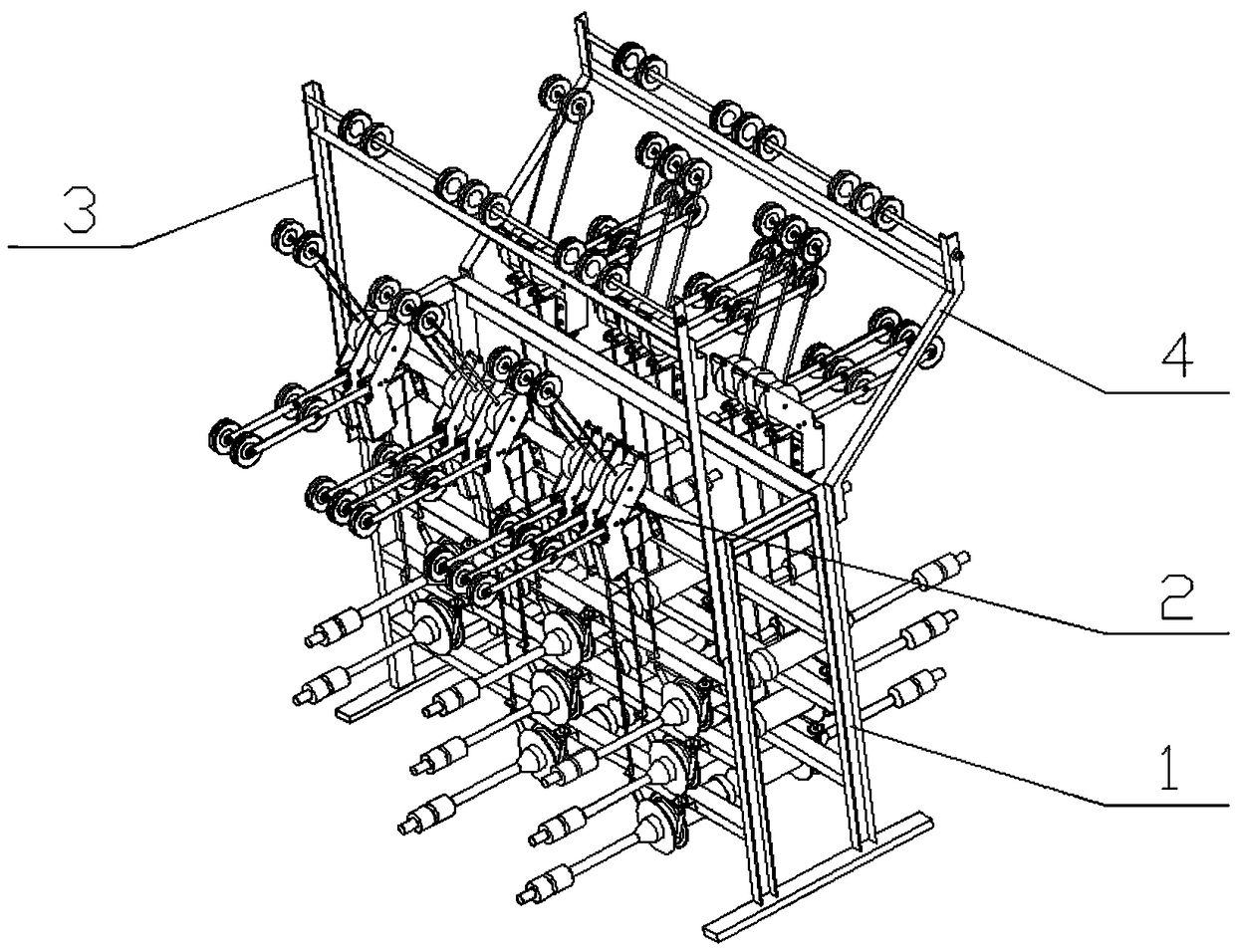

[0047] Such as figure 1 As shown, a device for merging cable core wires includes a base 1 and sixteen parallel wire units 2 arranged on the base 1, among which eight parallel wire units 2 are arranged on the front of the base 1, and the other eight parallel wire units The wire unit 2 is arranged on the back of the base 1. Since the wire receiving device used in conjunction with the device of this embodiment is arranged in the front direction of the base 1, in order to connect the cable cores of the eight parallel wire units 2 on the back of the base 1 The wire is conducted to the front, and a guide bracket 3 and a reversing bracket 4 are also provided on the top of the base 1. Eight parallel wire units 2 corresponding to the eight wire paralleling units 2 on the back of the base 1 are respectively arranged on the guide bracket 3 and the reversing bracket 4. Guide wheels and reversing wheels;

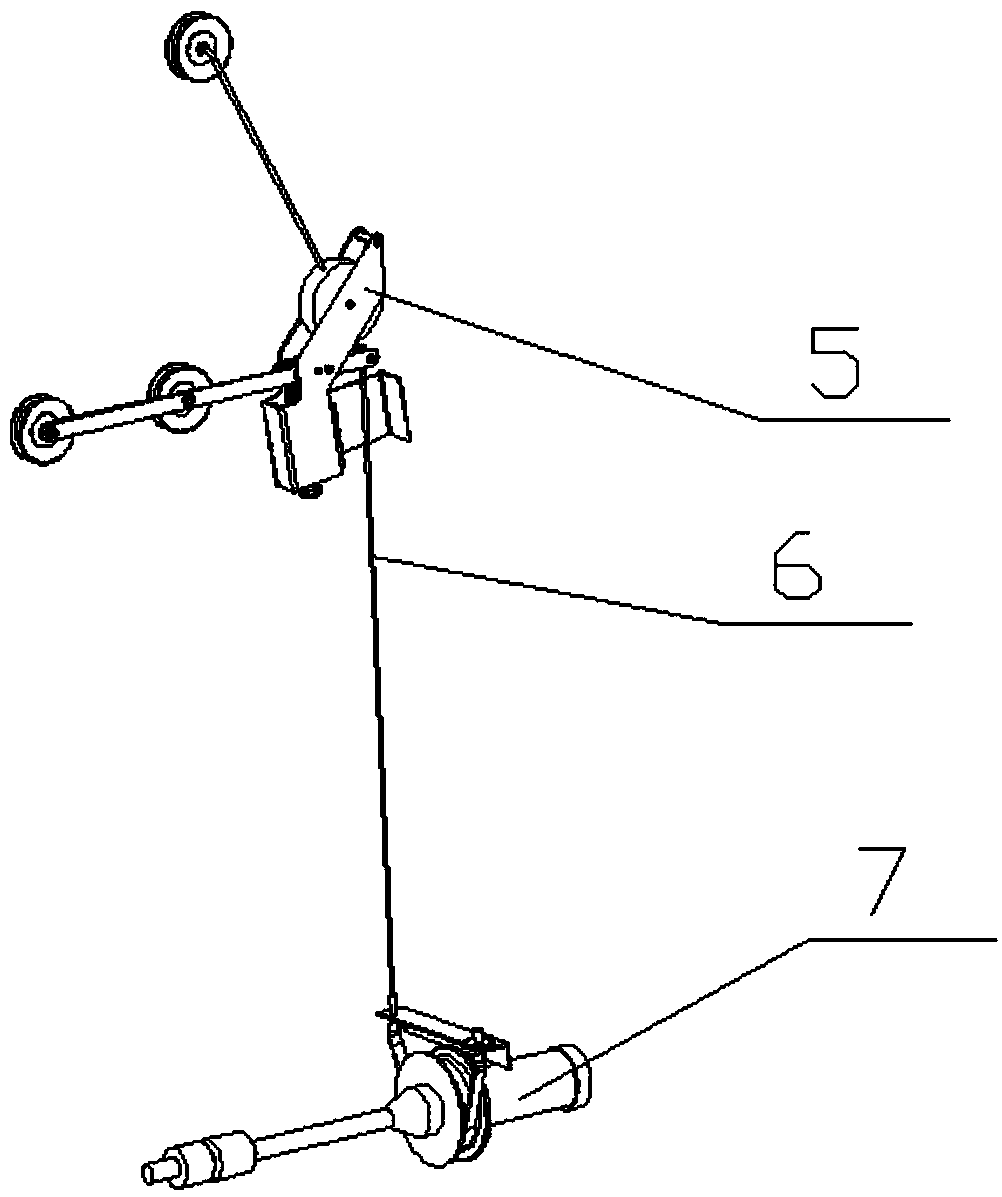

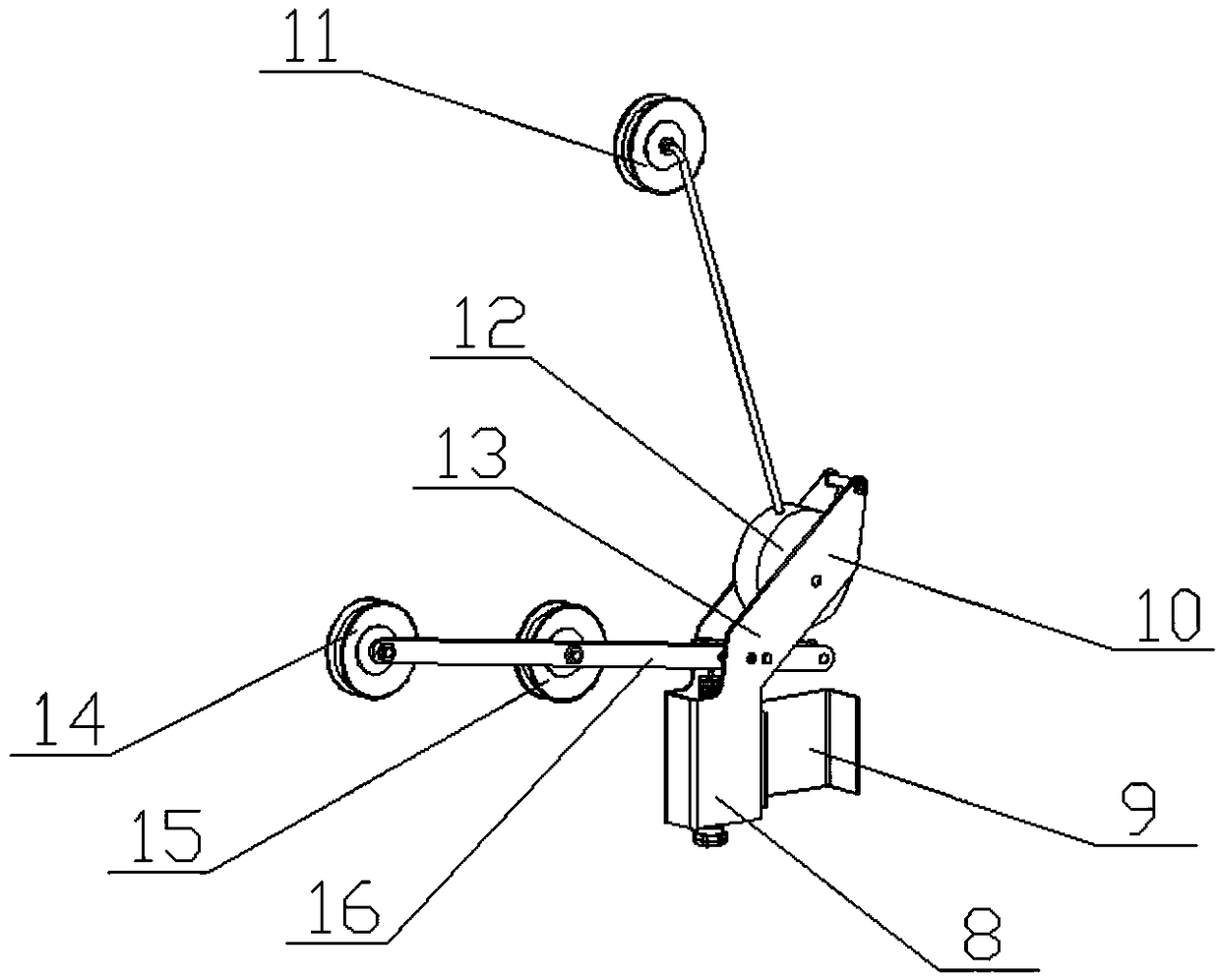

[0048] Such as figure 2 As shown, each doubling unit 2 includes a balance adjustm...

Embodiment 2

[0062] A device for merging cable core wires is the same as Embodiment 1, the difference is: as Figure 4 As shown, it also includes a fine-tuning spring 19; the left side of the pressure rod 16 and the hinge point of the adjustment box 13 is provided with a spring fixing rod 18; one end of the fine-tuning spring 19 is fixed on the spring fixing rod 18, and the other end is fixed on the lower end 8 Bottom; the bottom of the lower end 8 of the box is provided with a through hole; the end of the fine-tuning spring 19 fixed on the bottom of the lower end of the box 8 is provided with a fine-tuning rod 20; the fine-tuning rod 20 is provided with external threads; Knob 21; the fine-tuning knob 21 is provided with an internal thread corresponding to the external thread.

[0063] This embodiment can further produce beneficial effects on the basis of realizing the beneficial effects of Embodiment 1: the automatic adjustment balance function of Embodiment 1 still has the problem of low...

Embodiment 3

[0073] A device for merging cable core wires is the same as Embodiment 2, the difference is: as Figure 5 As shown, in this embodiment, in order to realize the manual adjustment of the tension between the tension belt 26 and the tension wheel groove 28, a screw is provided at the fixed end of the tension belt 26 and the tension unit seat 27; the screw passes through the tension unit seat Fix by nut after 27, screw rod rises when rotating nut like this, tension tension band 26, have increased the friction between tension band 26 and tension wheel groove 28.

[0074] A method for merging cable core wires, comprising the steps of:

[0075] S1. A plurality of parallel wire units 2 are arranged side by side on the base 1;

[0076] S2. Fix a plurality of large core wire reels wound with cable core wires on the wire release rods 23 of the multiple parallel wire units 2 arranged side by side in step S1 through locking sleeves 22;

[0077] S3. In step S2, one end of the respective ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com