Patents

Literature

36results about How to "Avoid the impact of production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

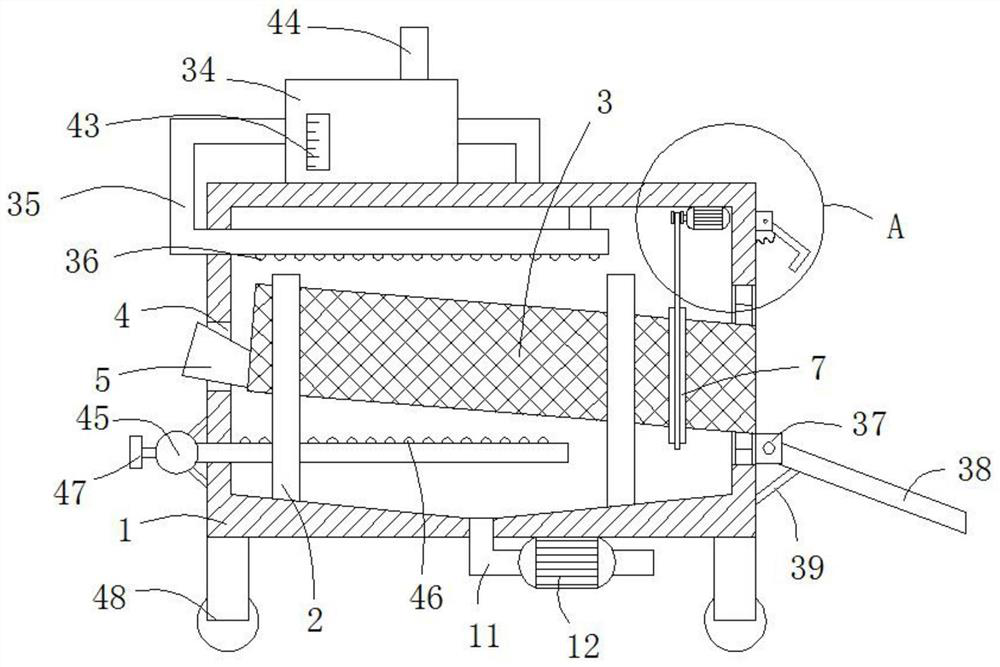

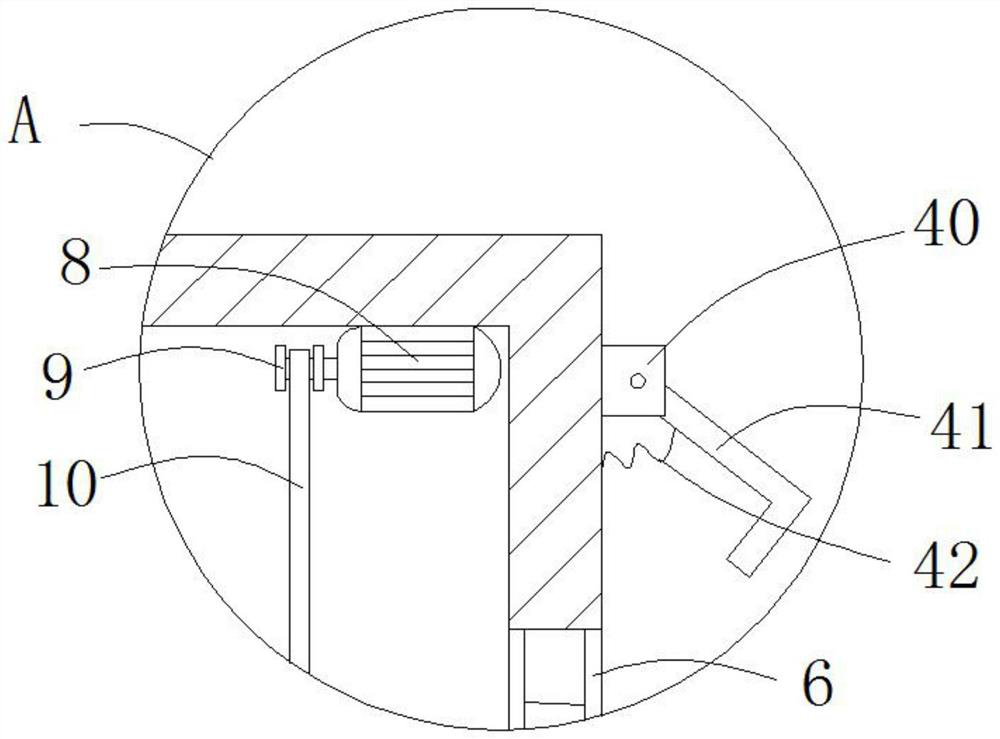

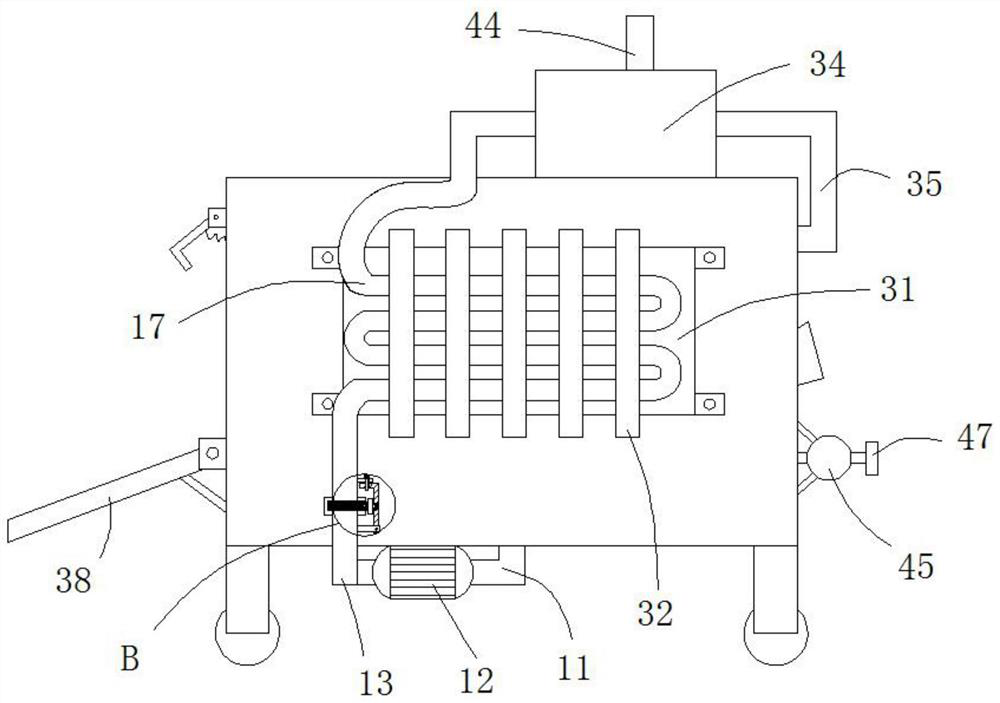

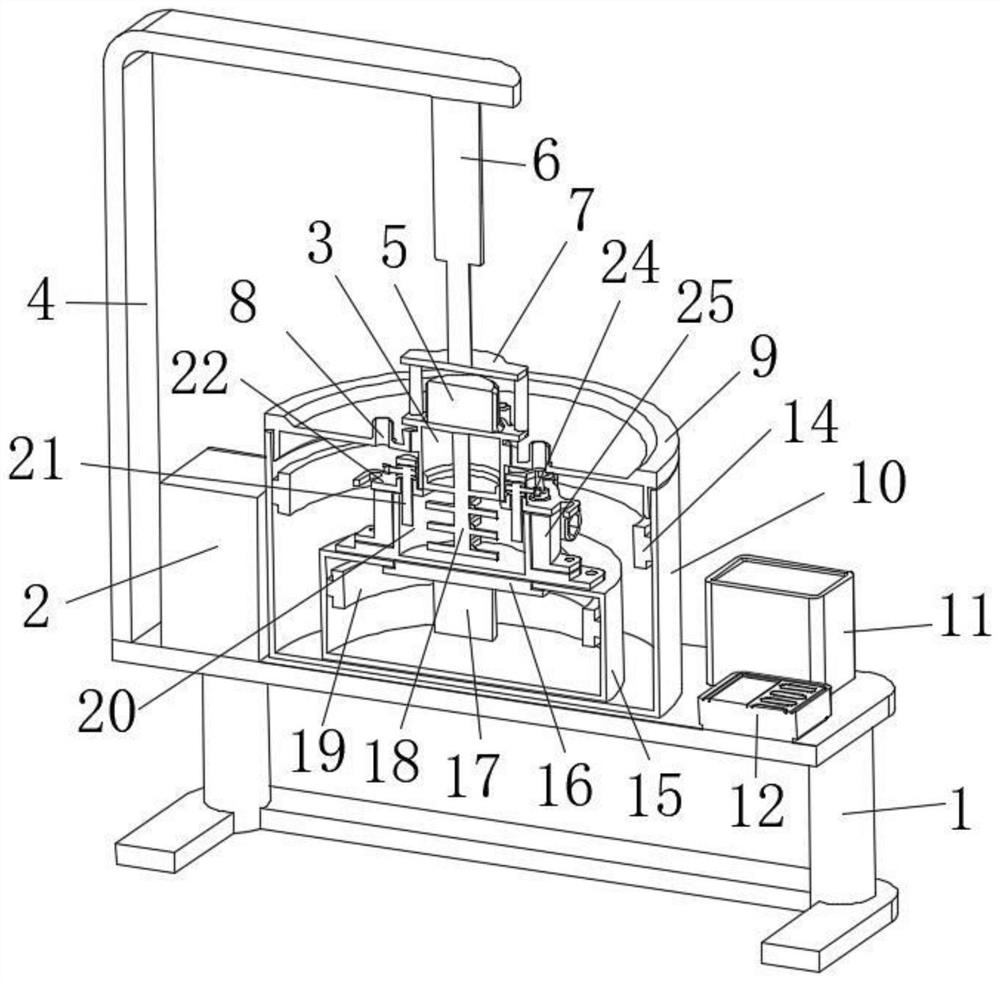

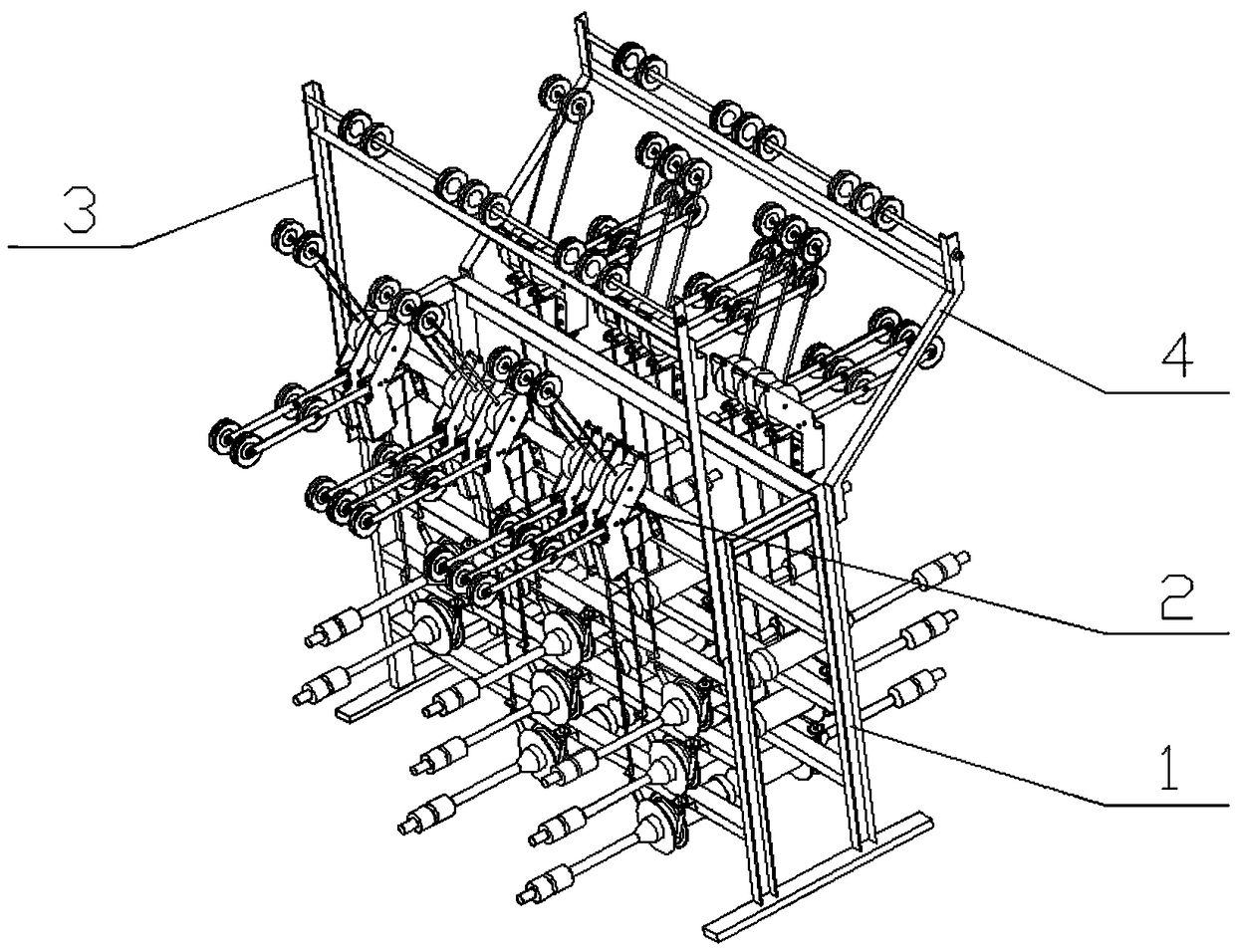

Intelligent 3D printing equipment

InactiveCN106985375AReduce labor intensityAvoid the impact of production efficiencyAdditive manufacturing with liquids3D object support structuresEngineering3d printer

Owner:南安市智德机械设备有限公司

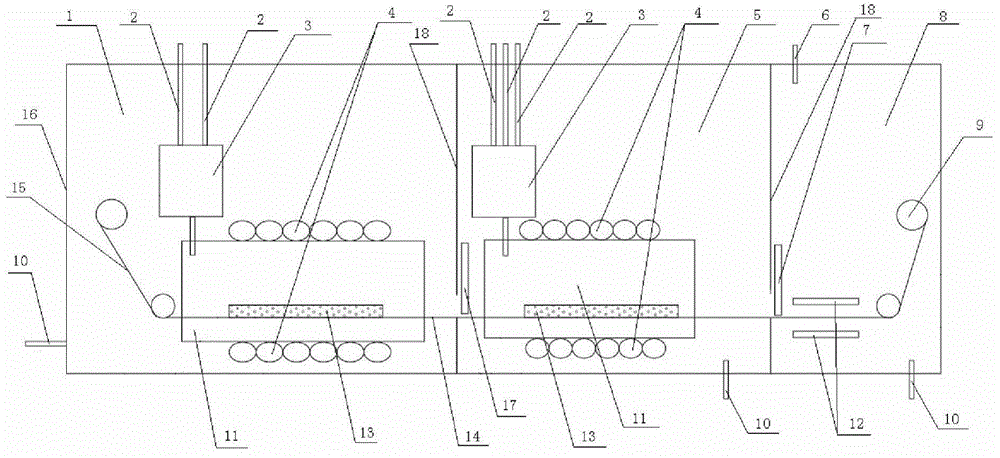

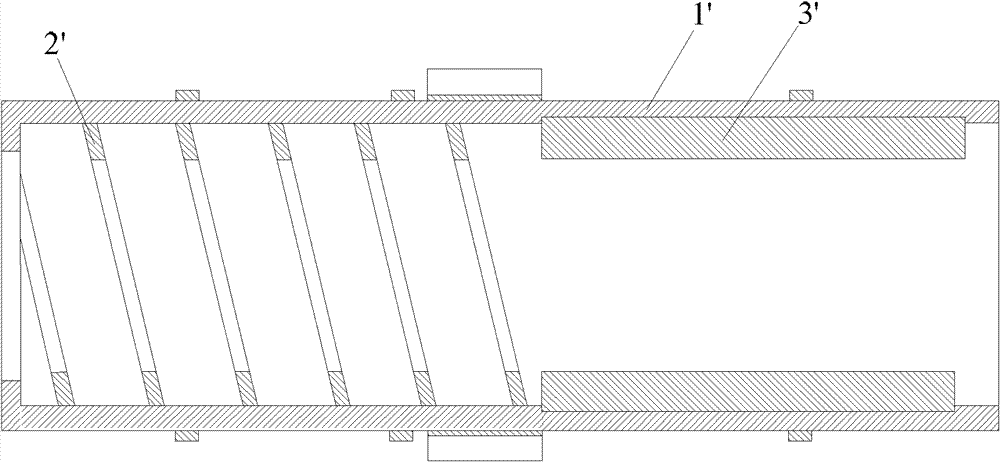

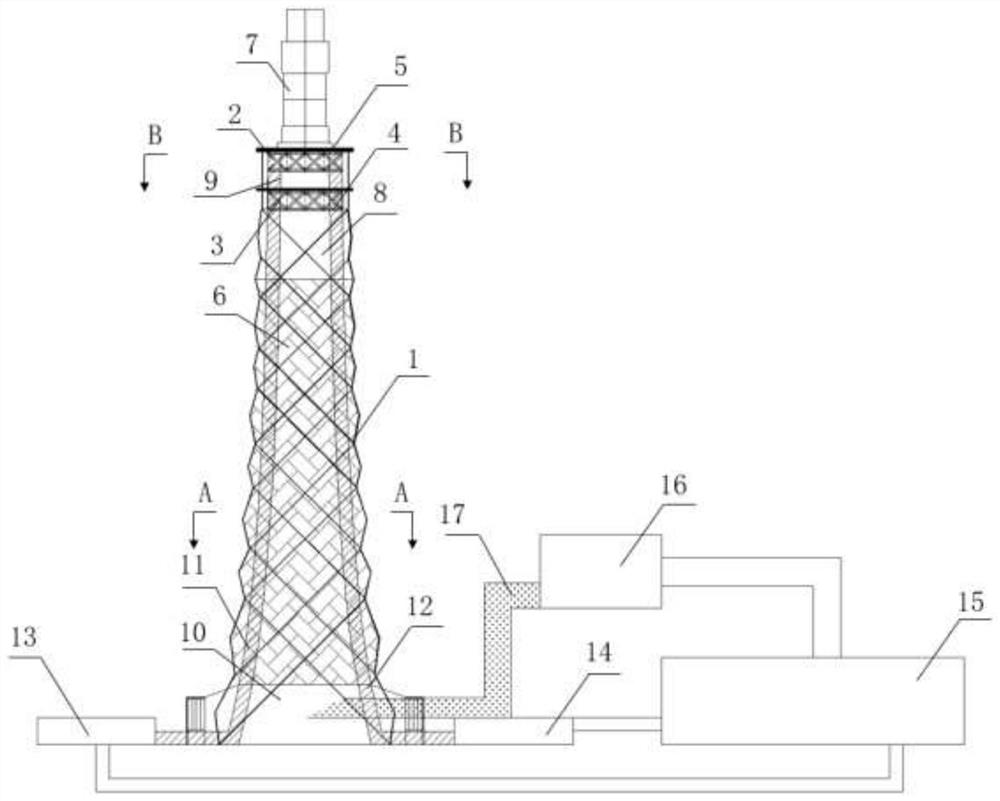

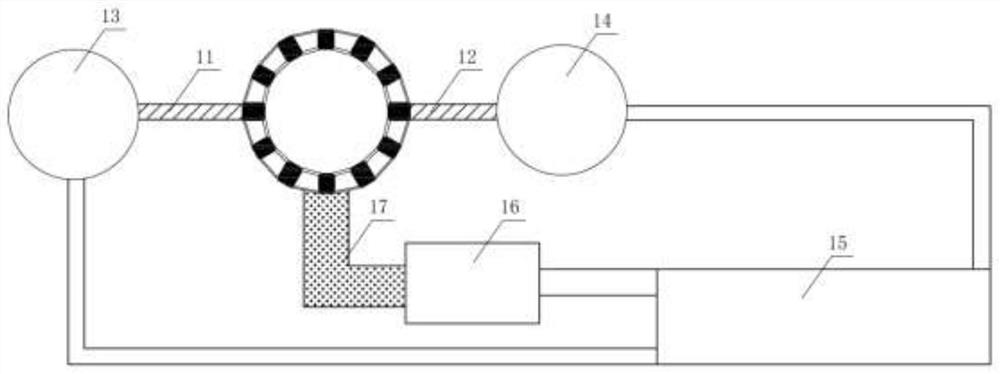

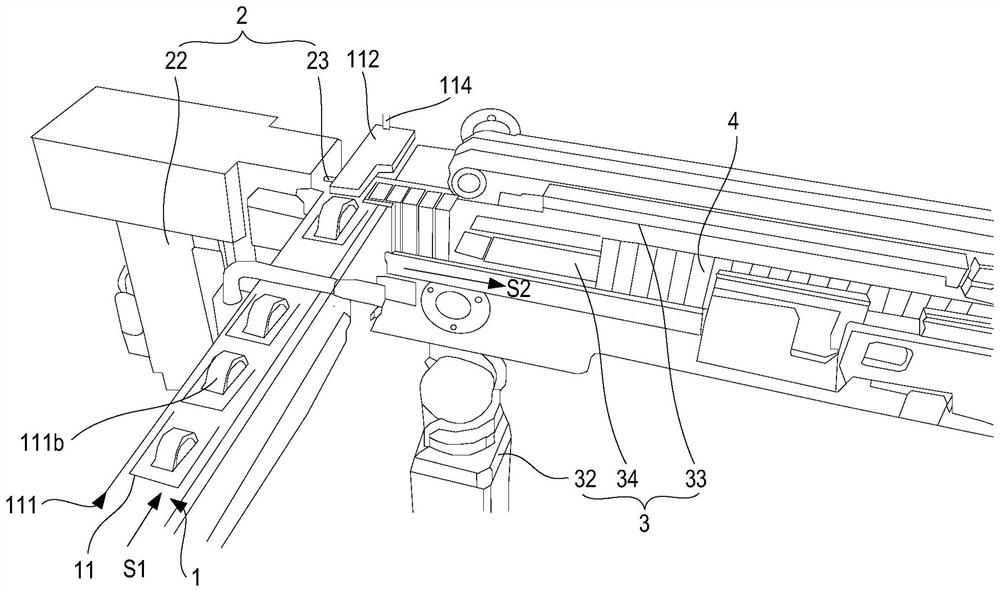

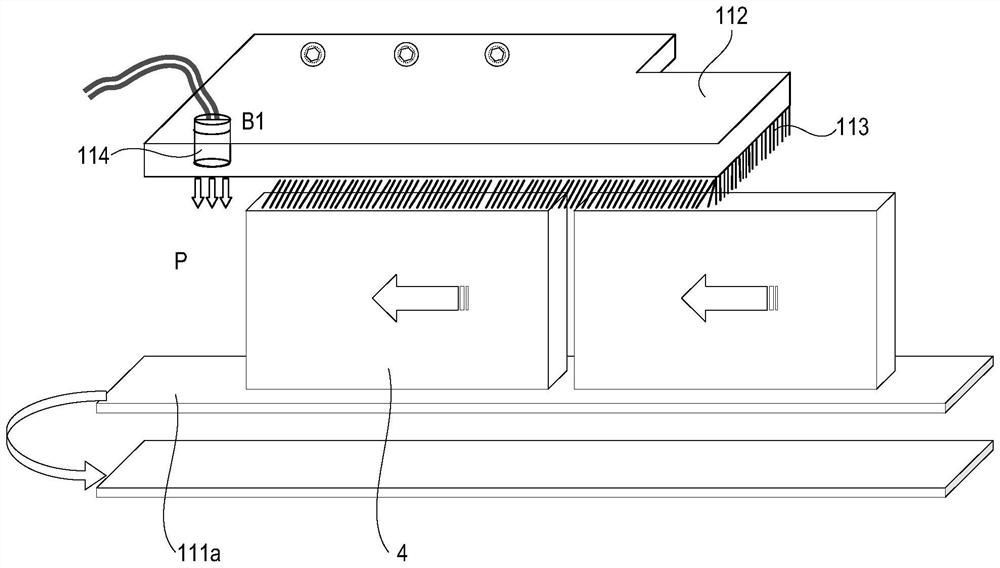

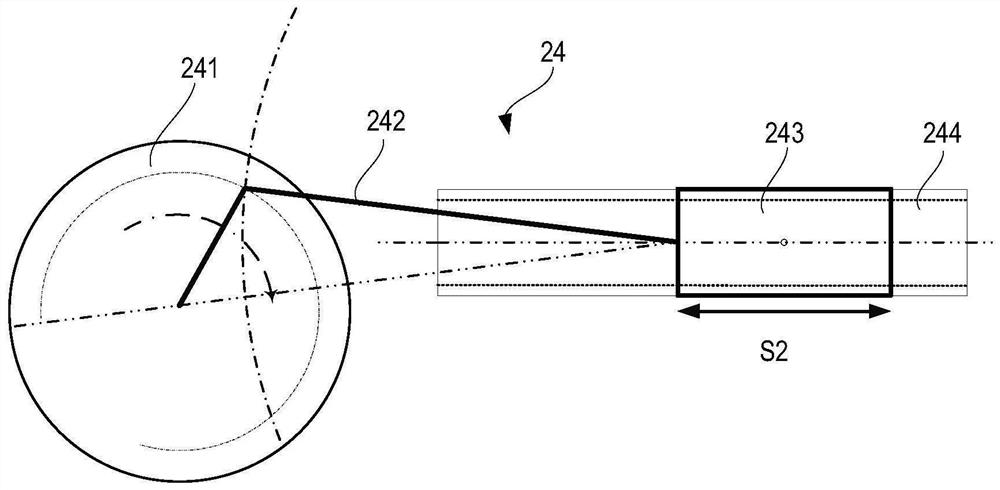

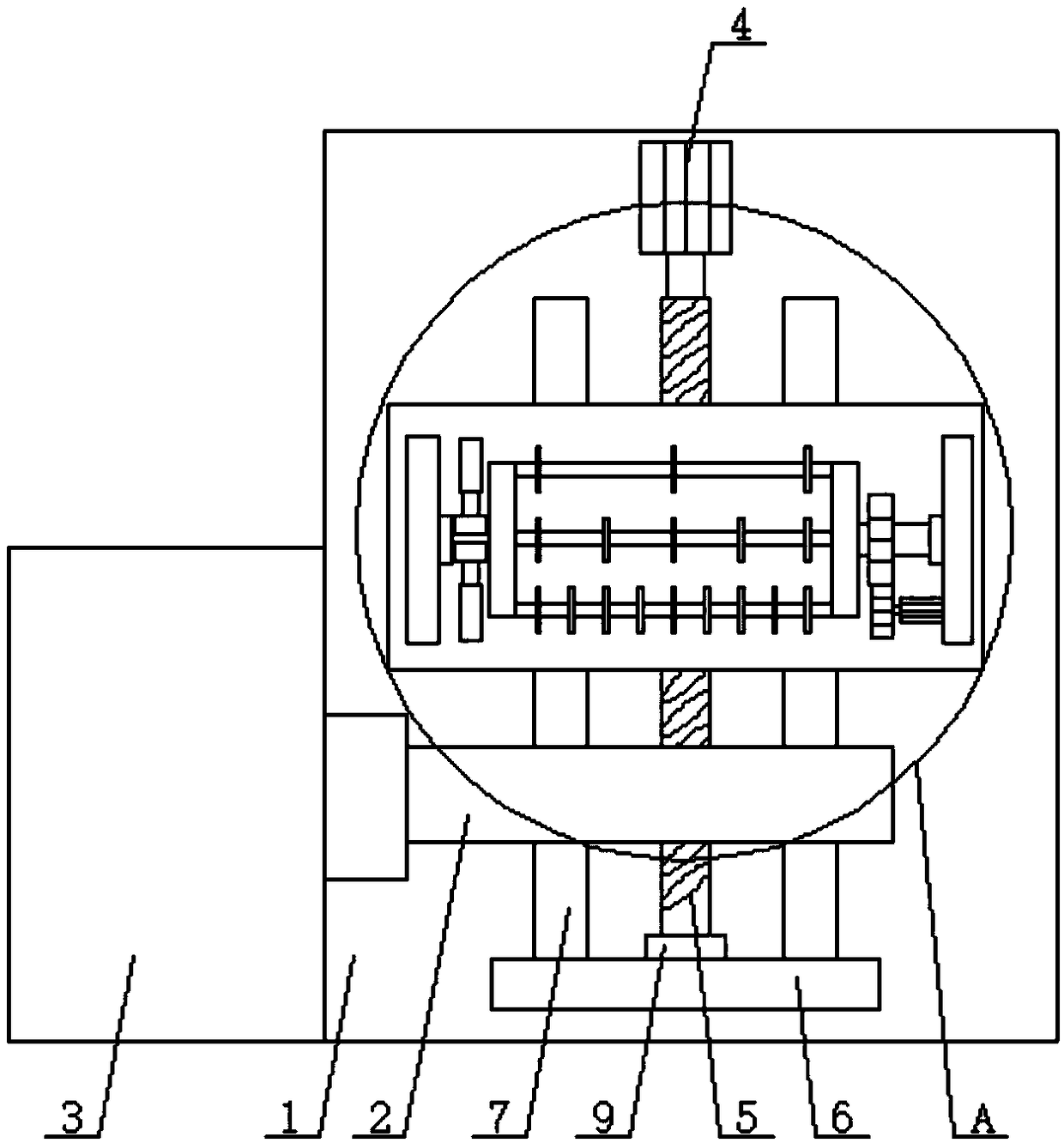

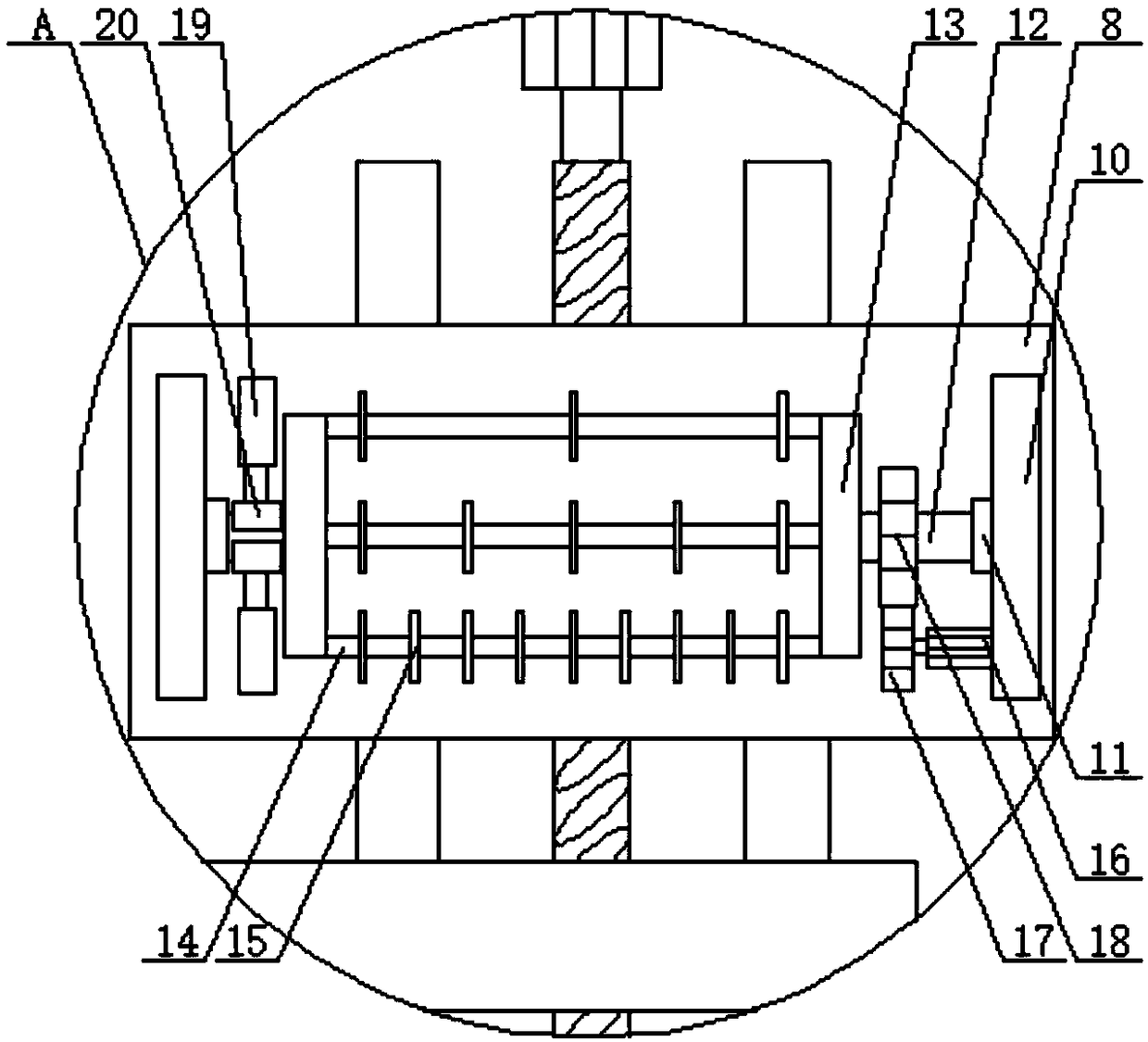

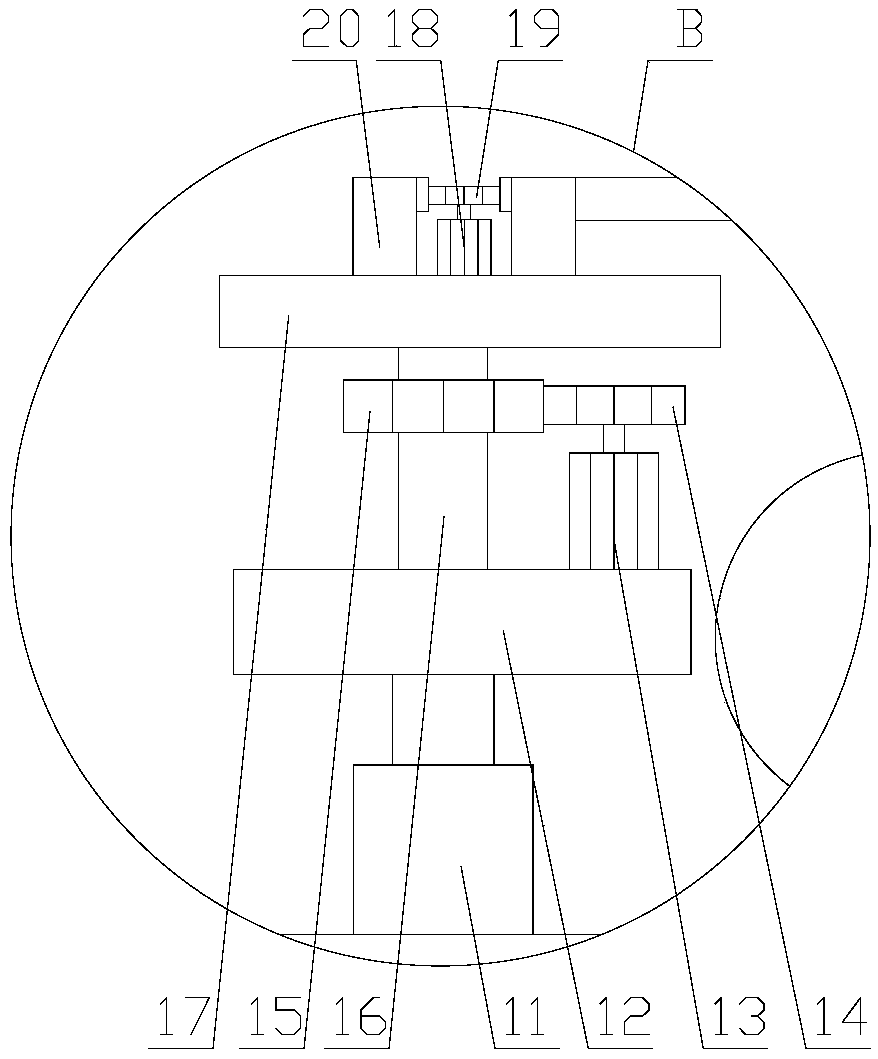

Equipment and method of continuously and rapidly preparing graphene under normal pressure

The invention relates to equipment and a method of continuously and rapidly preparing graphene under a normal pressure. The equipment comprises a box, a constant-temperature annealing cavity, a cooling growth cavity and a cooling cavity, wherein the box is separated into the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity; a gas intake tube, a gas mixing chamber and a reaction cavity are arranged in the constant-temperature annealing cavity and the cooling growth cavity respectively; the gas intake tube stretches in the gas mixing chamber; the gas mixing chamber is communicated with the reaction cavity; a cooling device is arranged in the cooling cavity; a feeding device and a cold gas tube are further arranged in the box; the feeding device penetrates through the reaction cavities and the cooling devices of the constant-temperature annealing cavity and the cooling growth cavity; the constant-temperature annealing cavity, the cooling growth cavity and the cooling cavity are provided with pressure release tubes. The method comprises the following steps: conveying a metal substrate in the constant-temperature annealing cavity and annealing at first; then conveying the metal substrate in the cooling growth cavity and reacting to grow graphene; finally conveying graphene in the cooling cavity and cooling. The equipment and method have the beneficial effects that preparation cycle is short, the equipment is simple in structure and convenient in operation, production efficiency is increased, and high economic benefits are achieved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

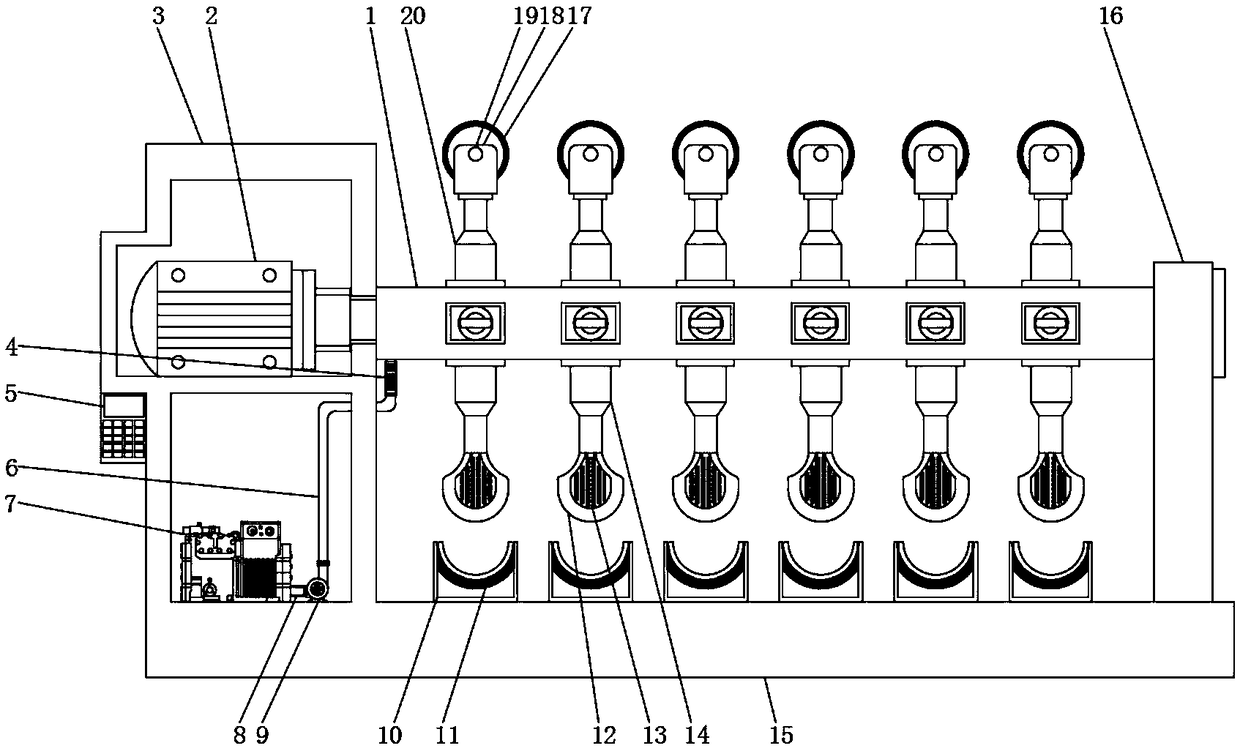

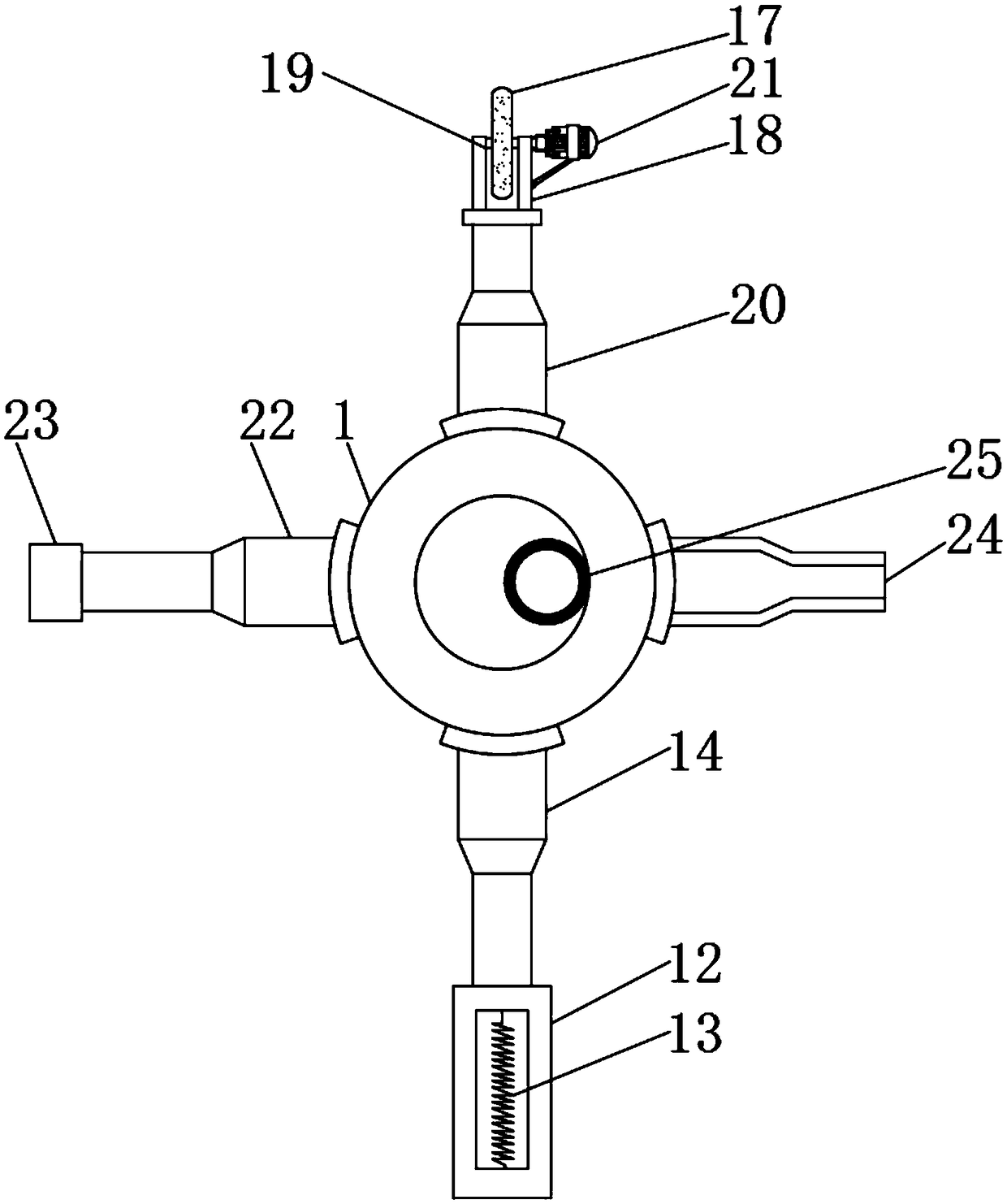

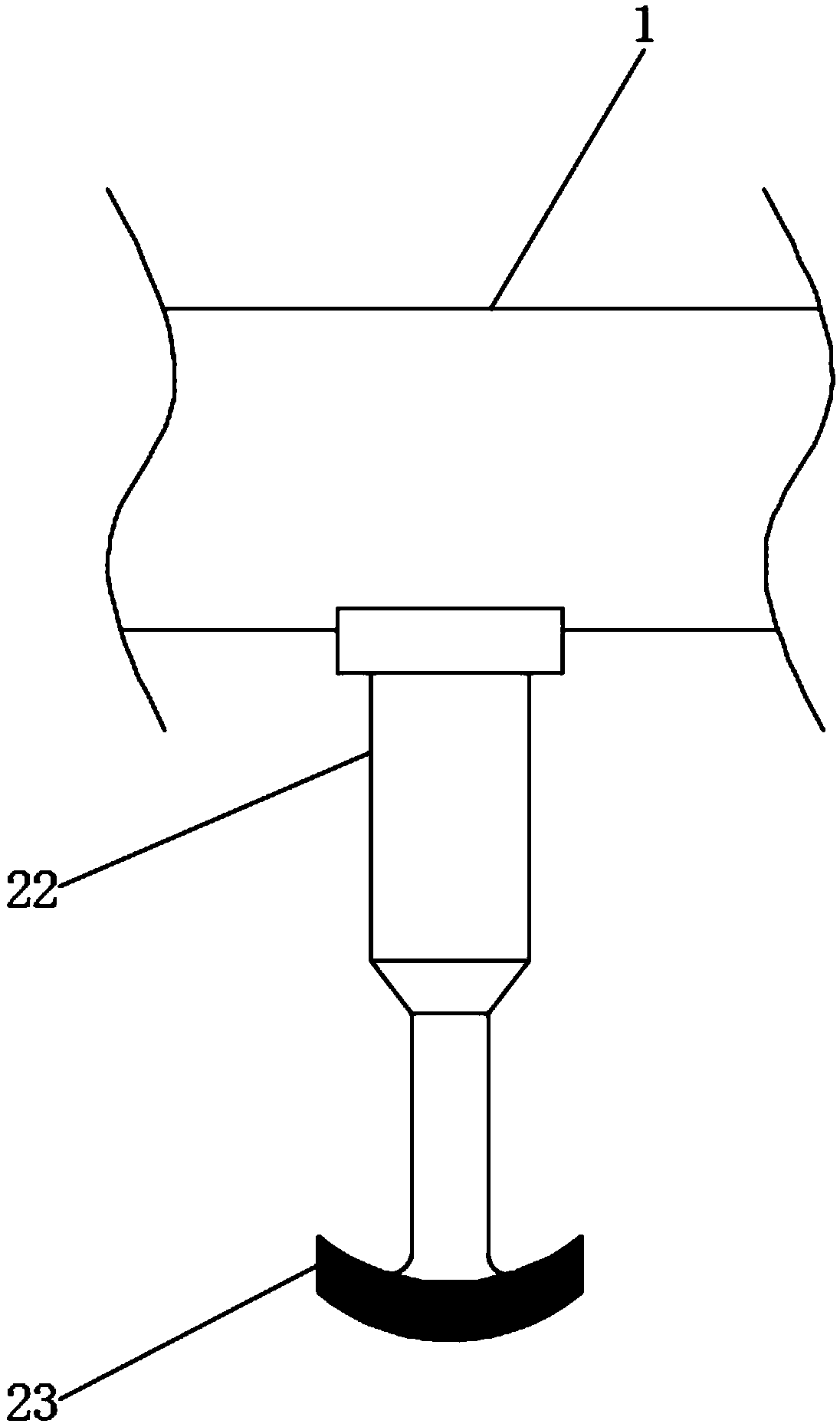

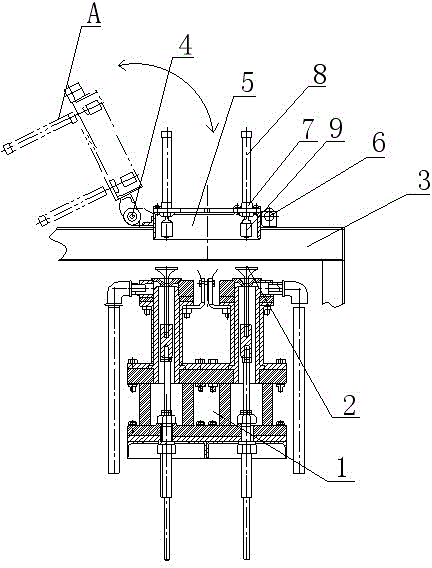

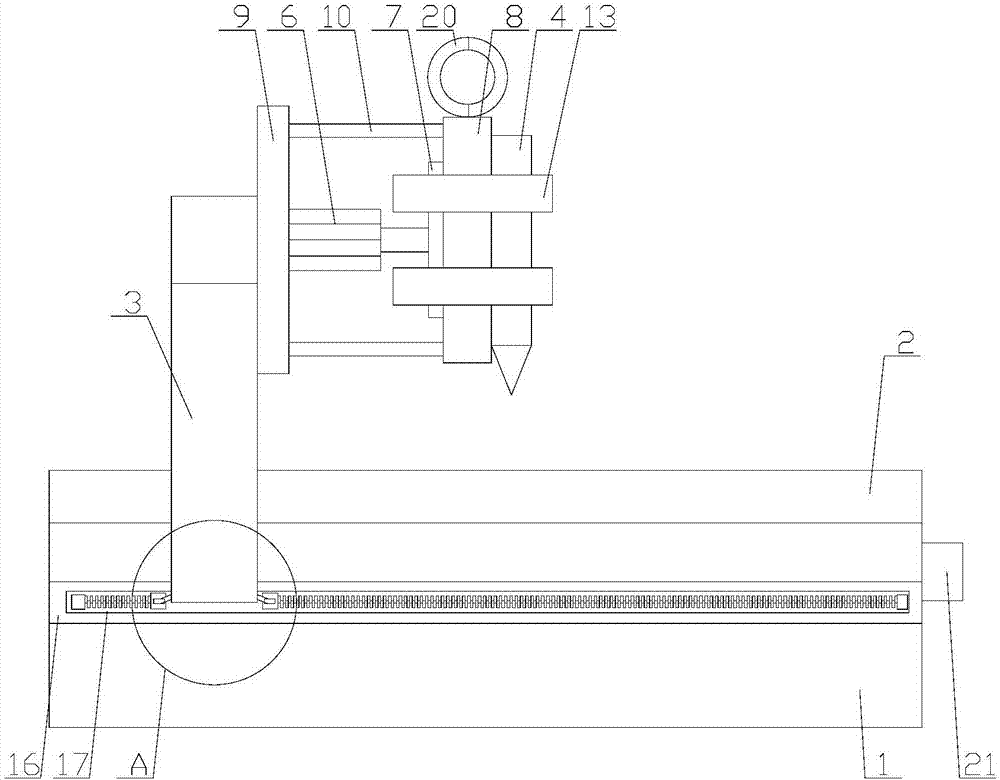

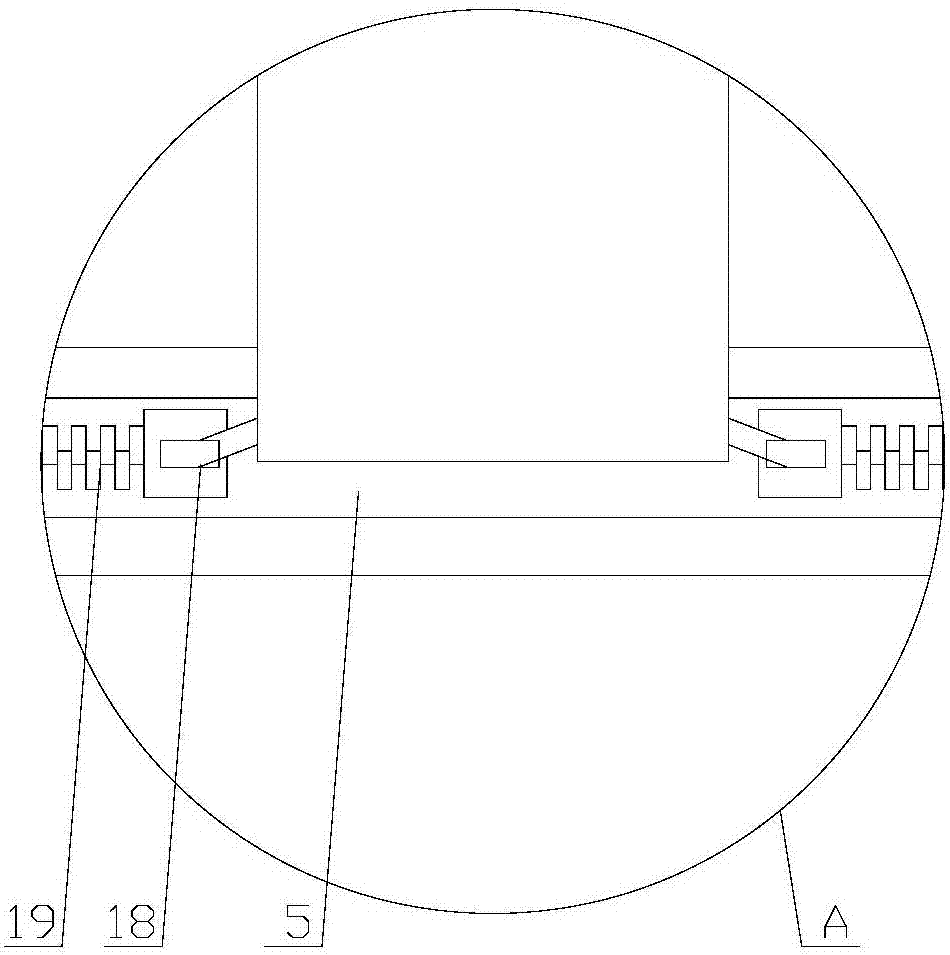

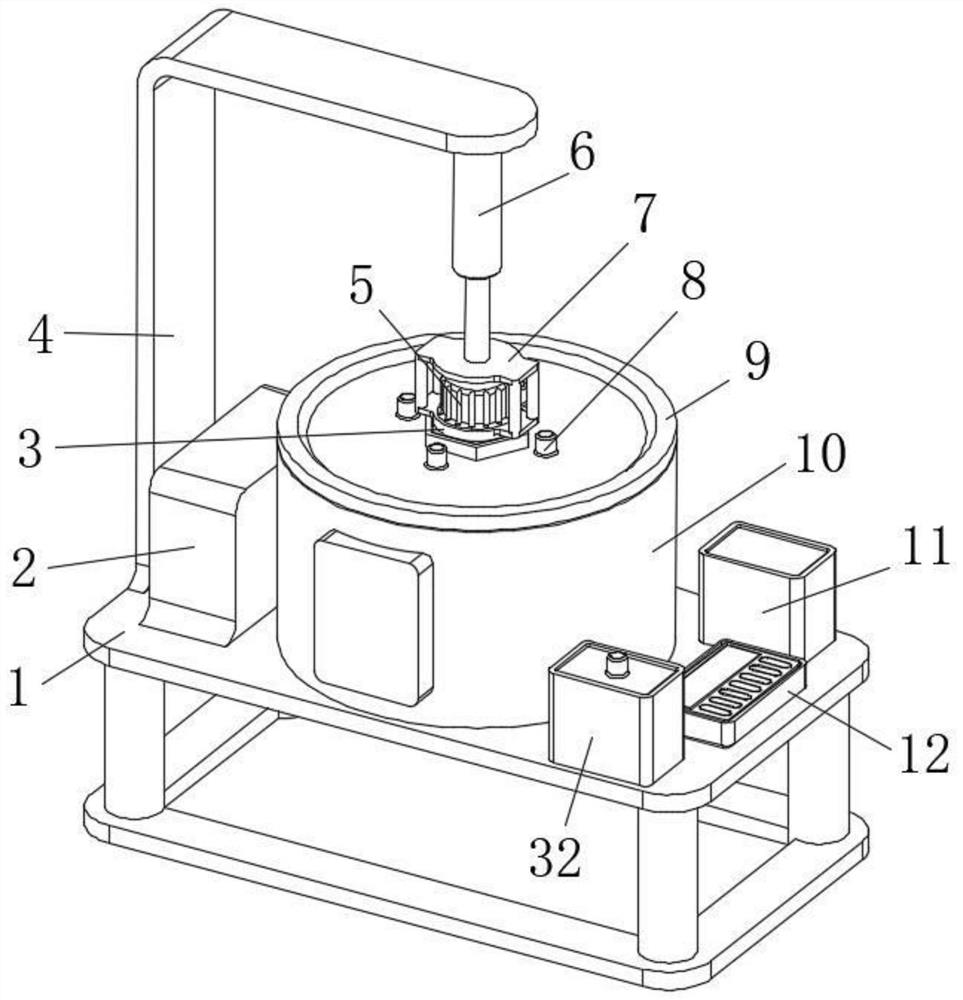

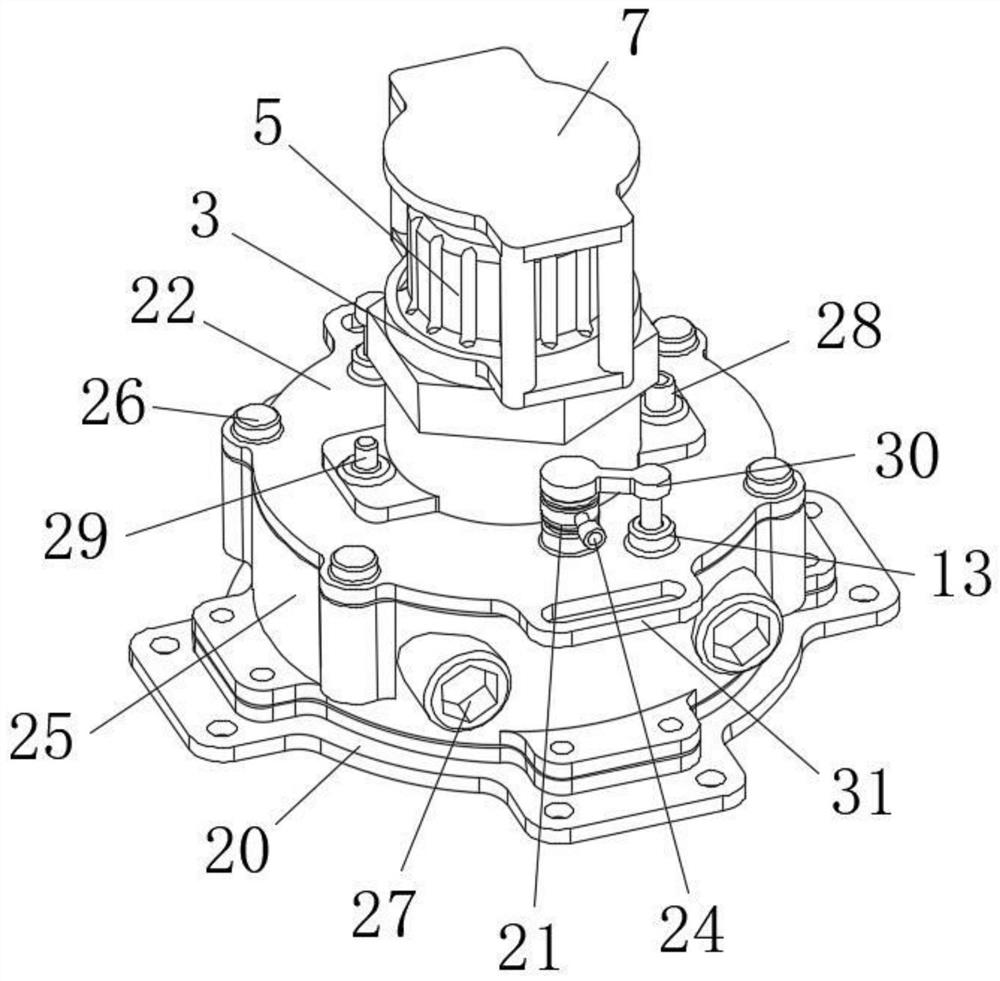

Six-station bearing bush production machine tool

PendingCN108608207AImprove ductilityEasy to shapeOther manufacturing equipments/toolsGrinding/polishing safety devicesElectric heatingEngineering

The invention discloses a six-station bearing bush production machine tool. The machine tool comprises a rotating shaft and a machine case; the machine case is arranged at one end of the rotating shaft, a rotating motor is arranged in the machine case, one end of the rotating motor penetrates the surface of the machine case and is rotatably connected with the rotating shaft, the surface of the rotating shaft is welded with a press head telescopic rod, a press head is welded to the bottom face of the press head telescopic rod, an electric heating wire is arranged in the press head, an electromagnet telescopic rod is welded to the position, on the surface of the rotating shaft, of one side of the press head telescopic rod, and an electromagnet is welded to one end of the electromagnet telescopic rod. The electric heating wire and a press base electromagnet are arranged, the electric heating wire is arranged in the press head, after powering on, the press head is heated, the heated presshead moves downwards through the press head telescopic rod, in the process of making contact with a bearing bush raw material, the bearing bush raw material is heated, due to the fact that most bearing bush materials are metal, in the process of making contact with the high-pressure press head, the strength is reduced, and extension is improved.

Owner:盐城市精派组合机床有限公司

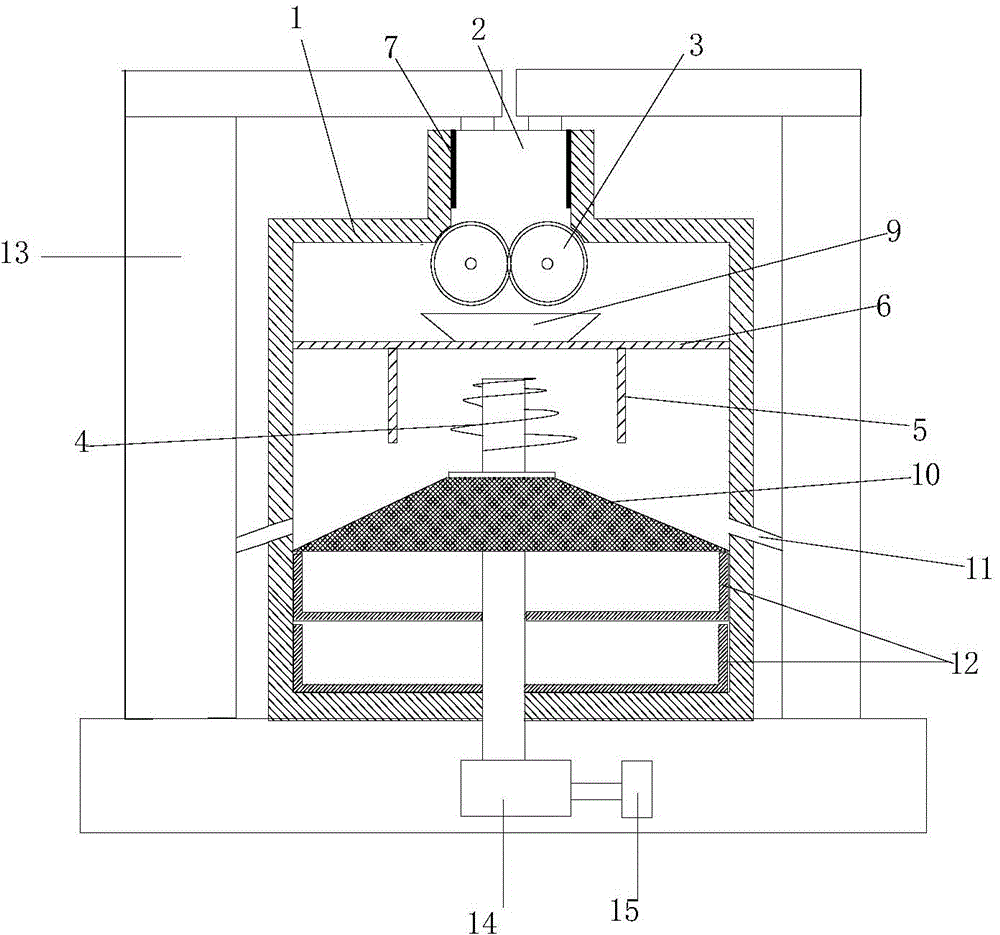

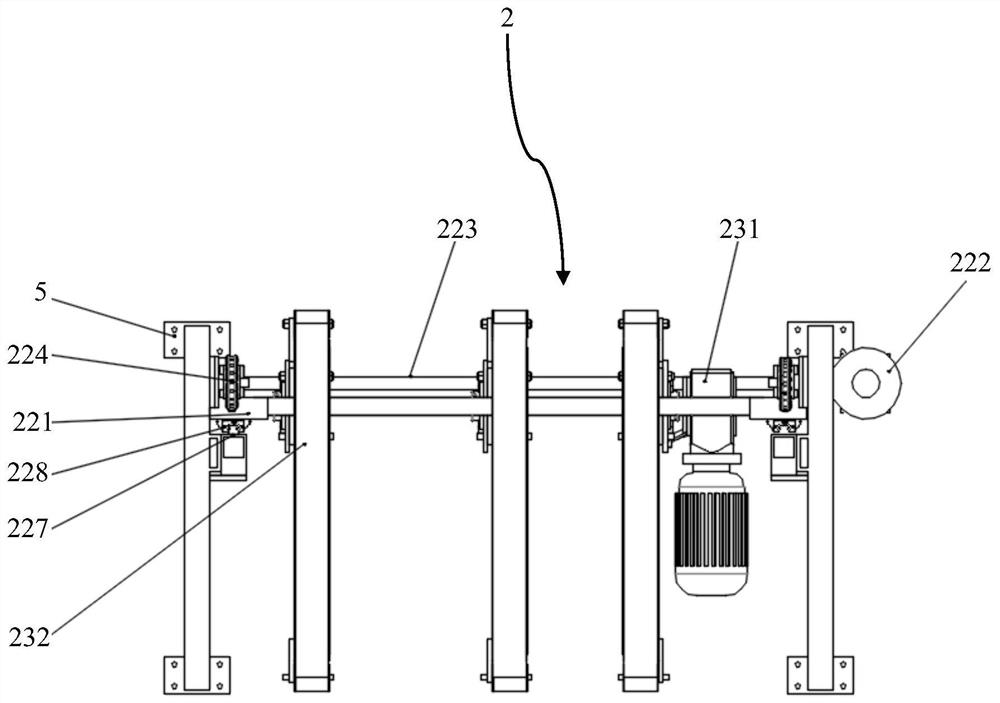

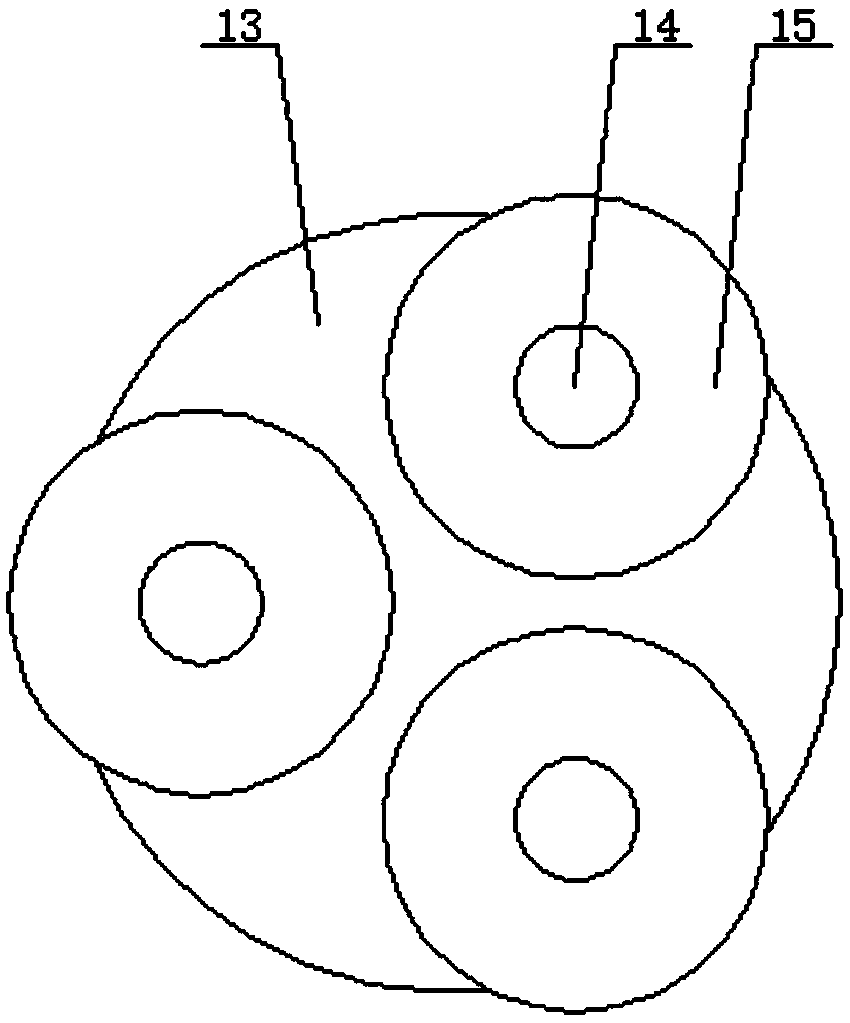

Material crushing and recycling mechanism

InactiveCN105772192AEffective cutting and crushingEffectively and fully cut and crushedGrain treatmentsSpiral bladeDrive shaft

The invention discloses a material crushing and recycling mechanism. The material crushing and recycling mechanism comprises a crushing device and a screening device which are driven by a power mechanism, wherein the crushing device comprises two rolls and a spiral blade; the two rolls are arranged in a feeding hole in a crushing bin in a double-roll manner; the spiral blade of which the axis is perpendicular to the horizontal direction faces the lower parts of the rolls and is connected to a rotary shaft; the power mechanism comprises a drive motor, a speed reducer and a transmission shaft; one end of the transmission shaft is in transmission fit to the power output shaft of the speed reducer; and the other end of the transmission shaft is in transmission fit to the rotary shaft. The material crushing and recycling mechanism can be used for cutting and crushing materials effectively and sufficiently, and can remove the materials which do not meet the crushing requirements by filtering, so that the materials are screened and discharged efficiently and quickly, blockage of a filter screen and material conveying blockage are avoided, and the processing precision and the processing efficiency are greatly improved; and meanwhile, influence, caused by frequent maintenance, on the production efficiency is also avoided, and the materials which do not meet the requirements can be recycled and then are circularly processed again.

Owner:CHONGQING QIFU MACHINERY

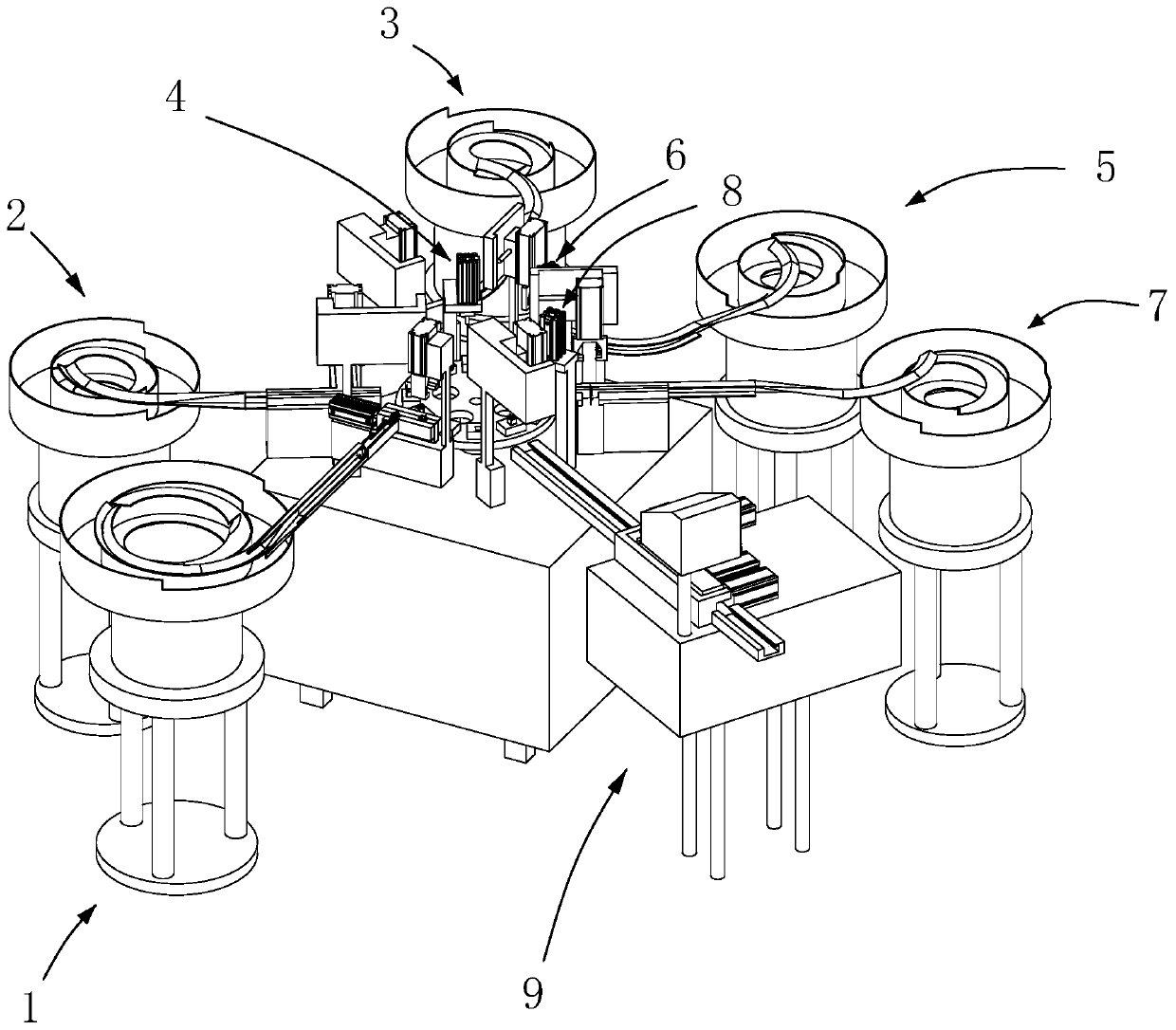

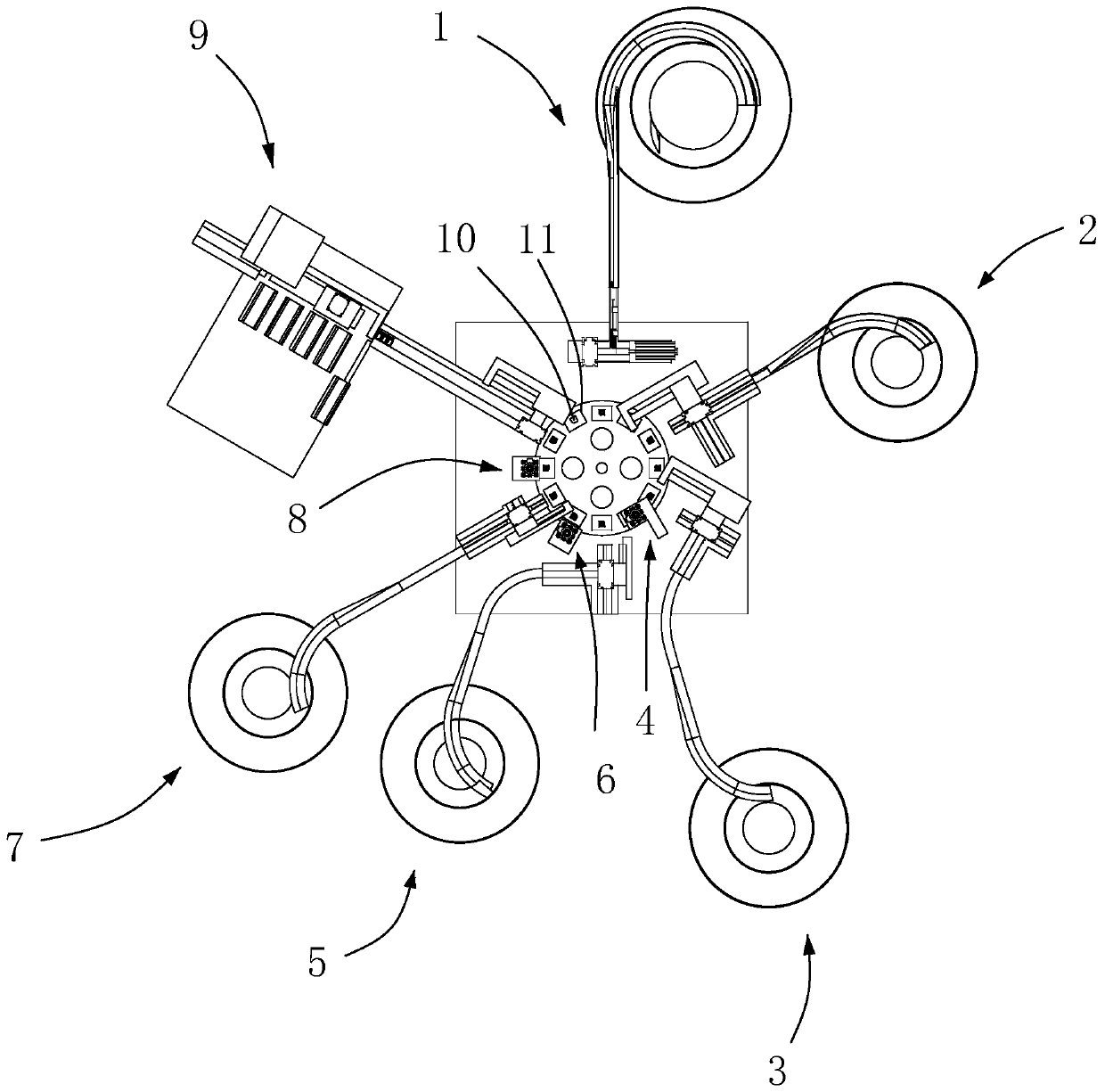

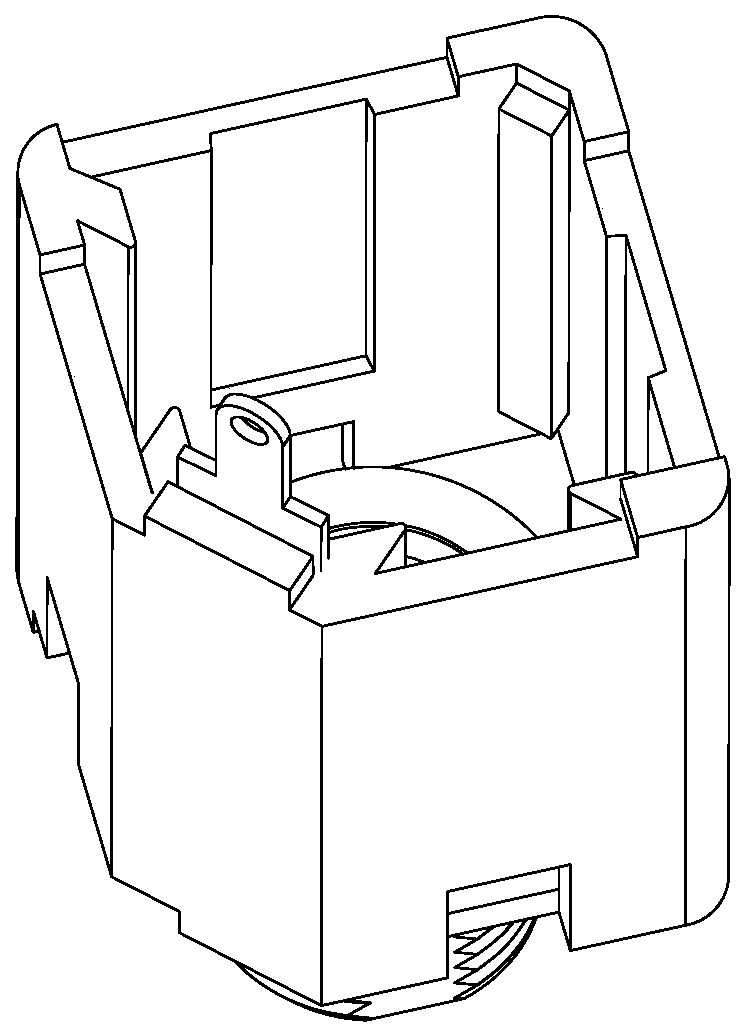

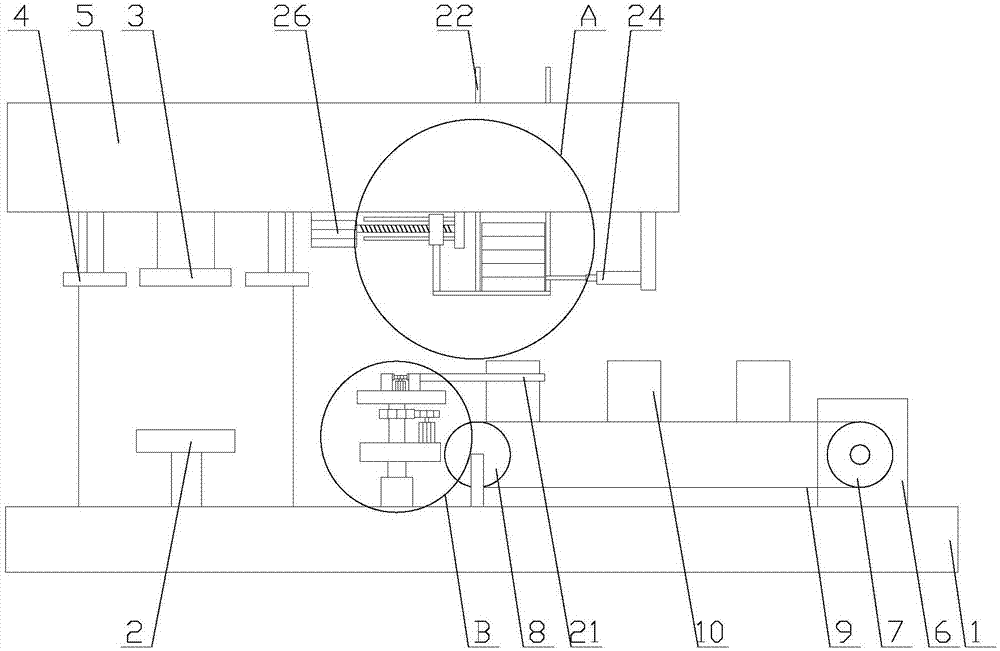

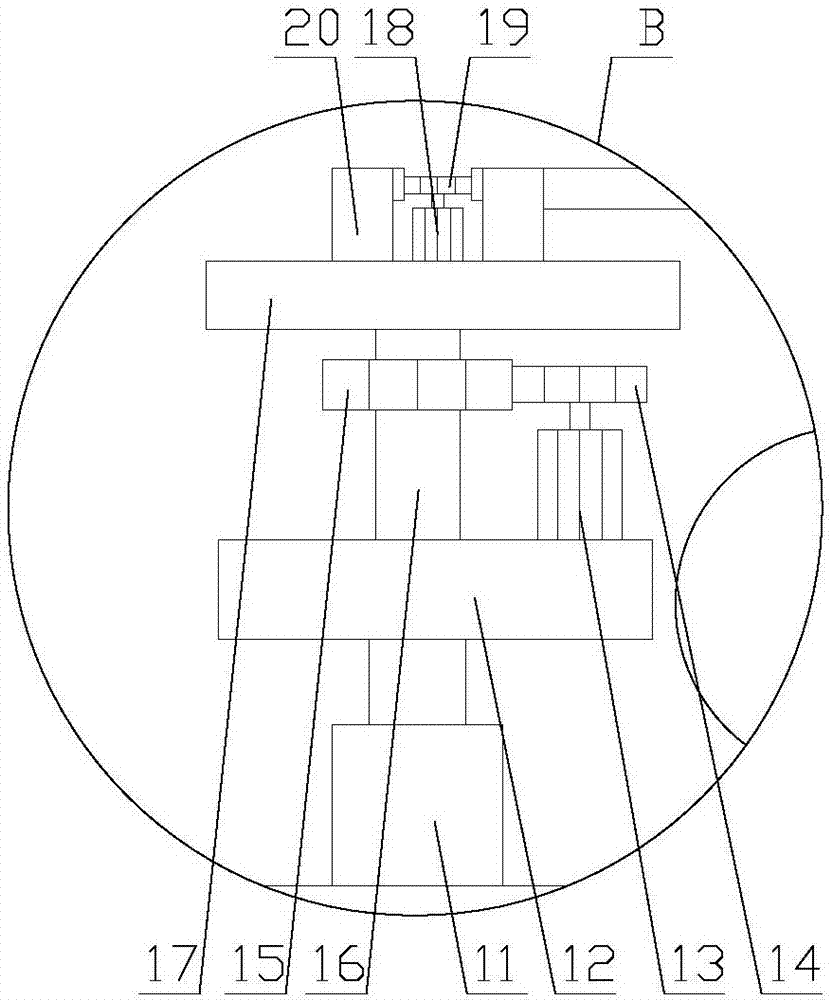

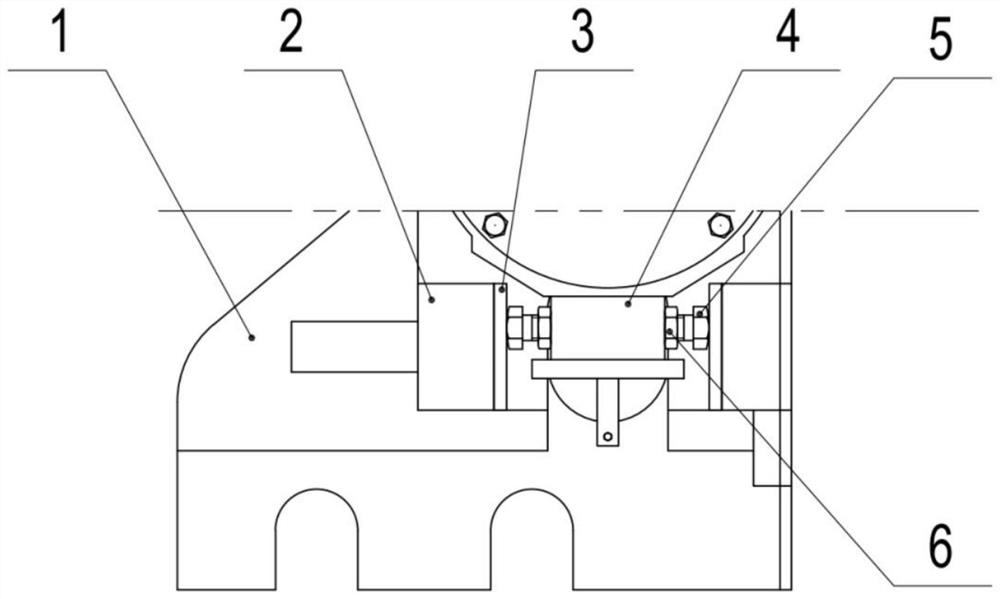

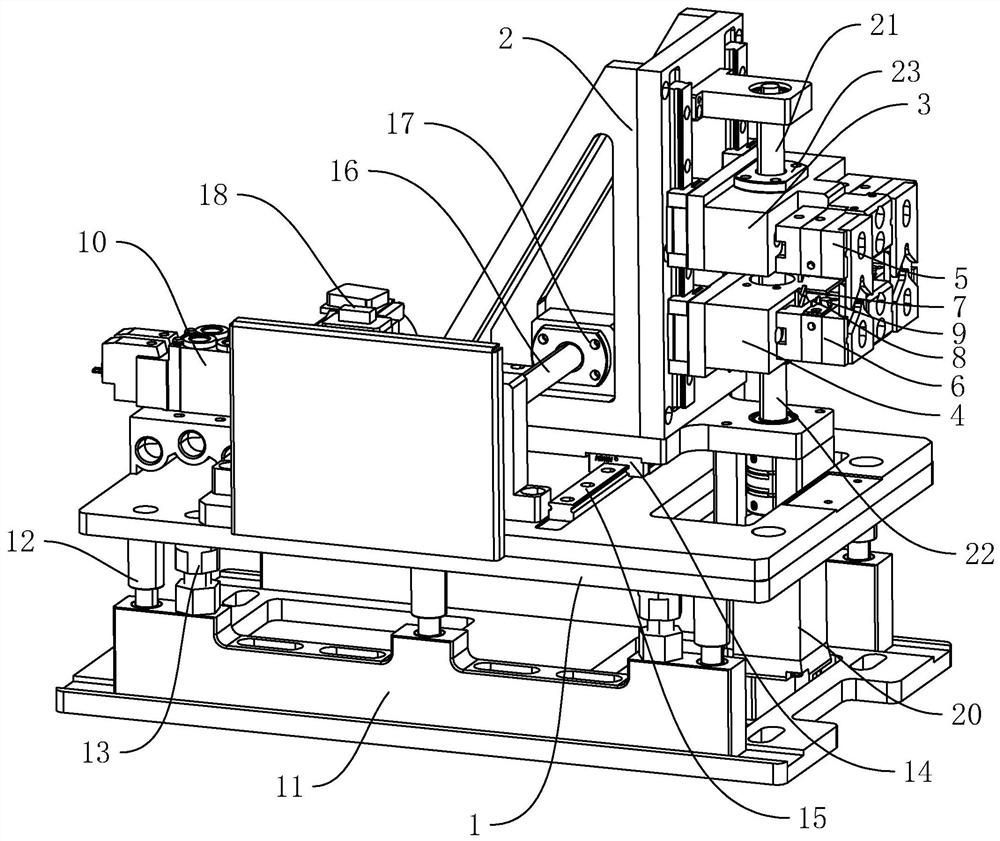

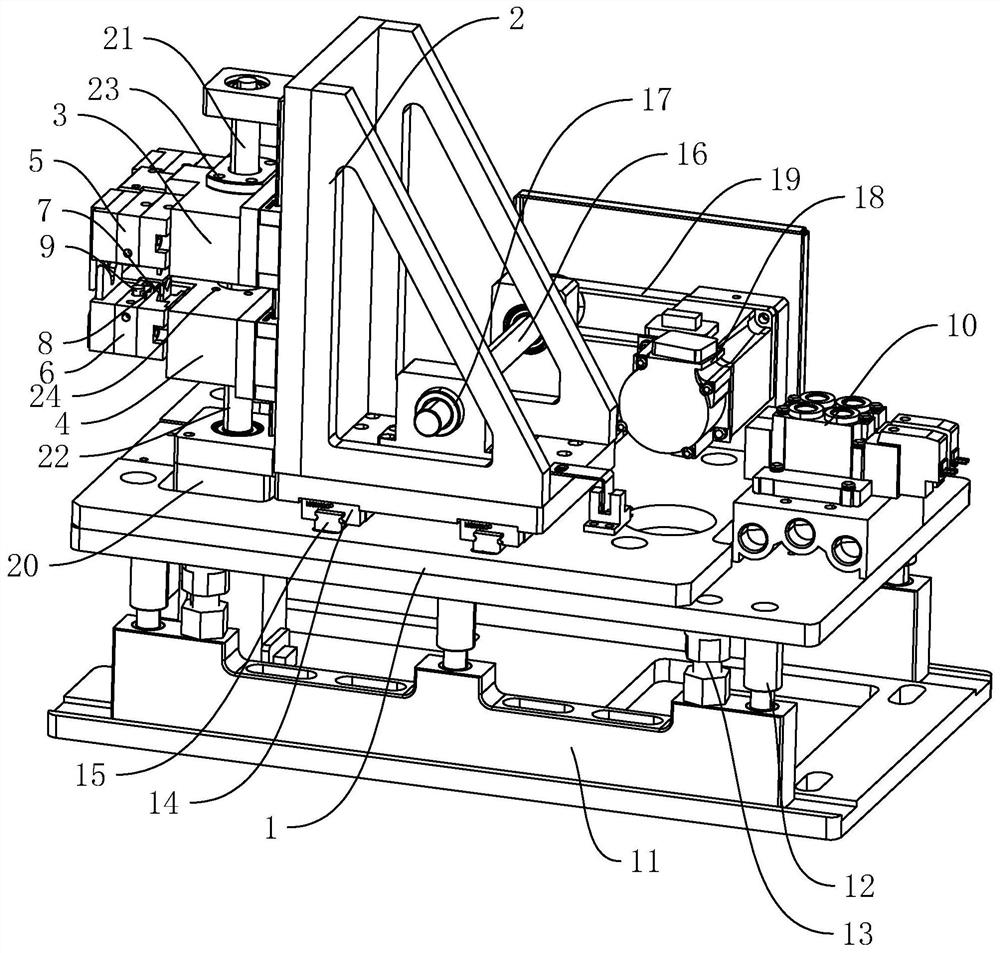

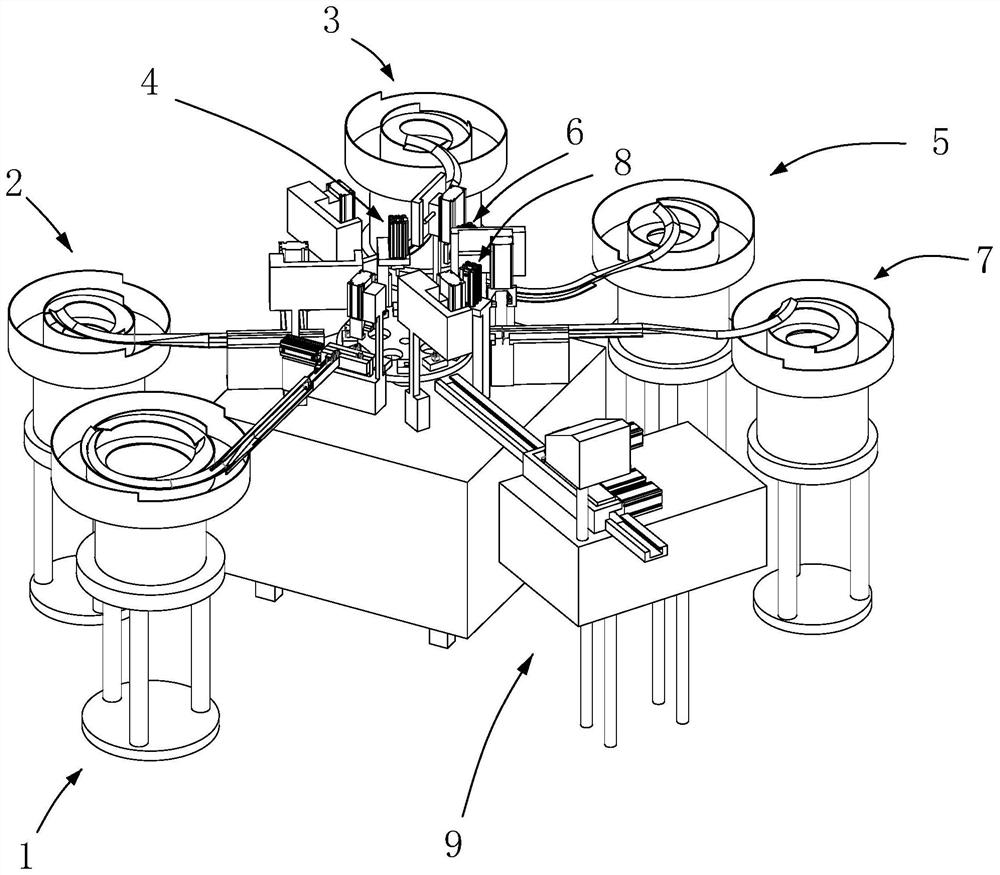

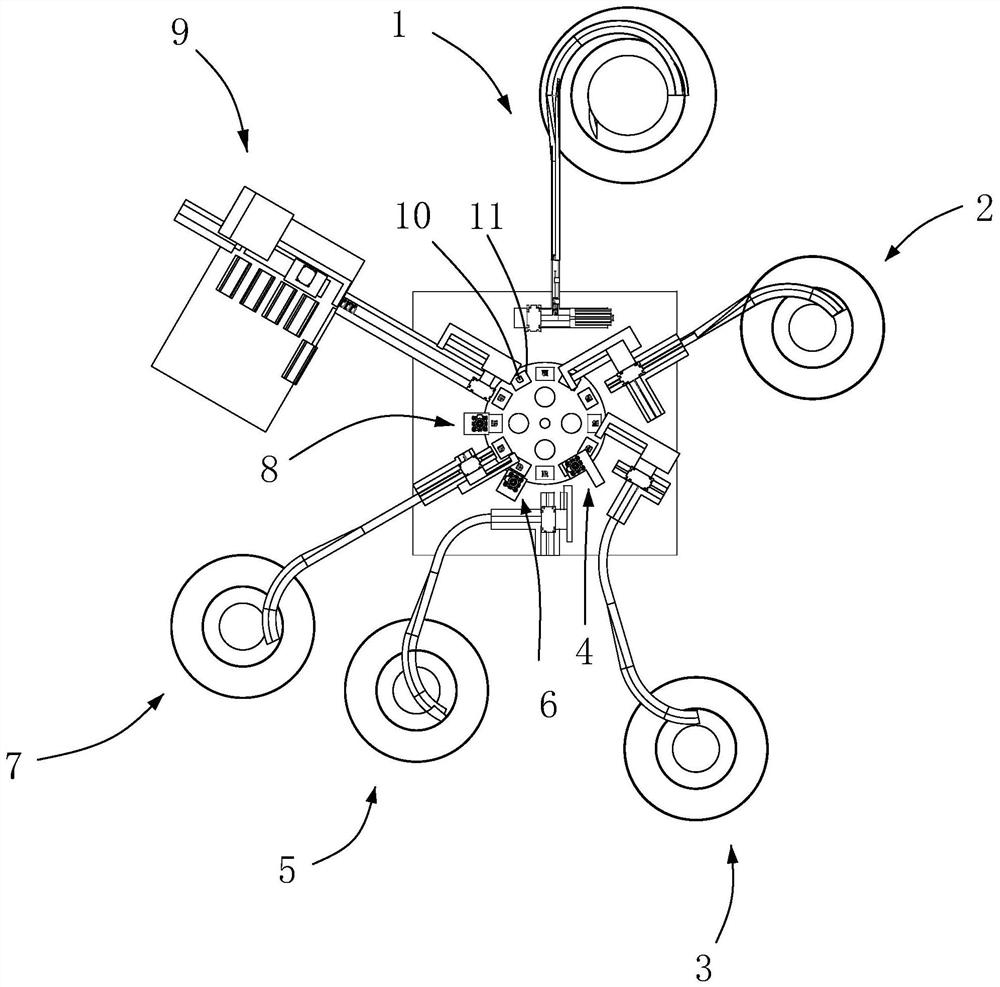

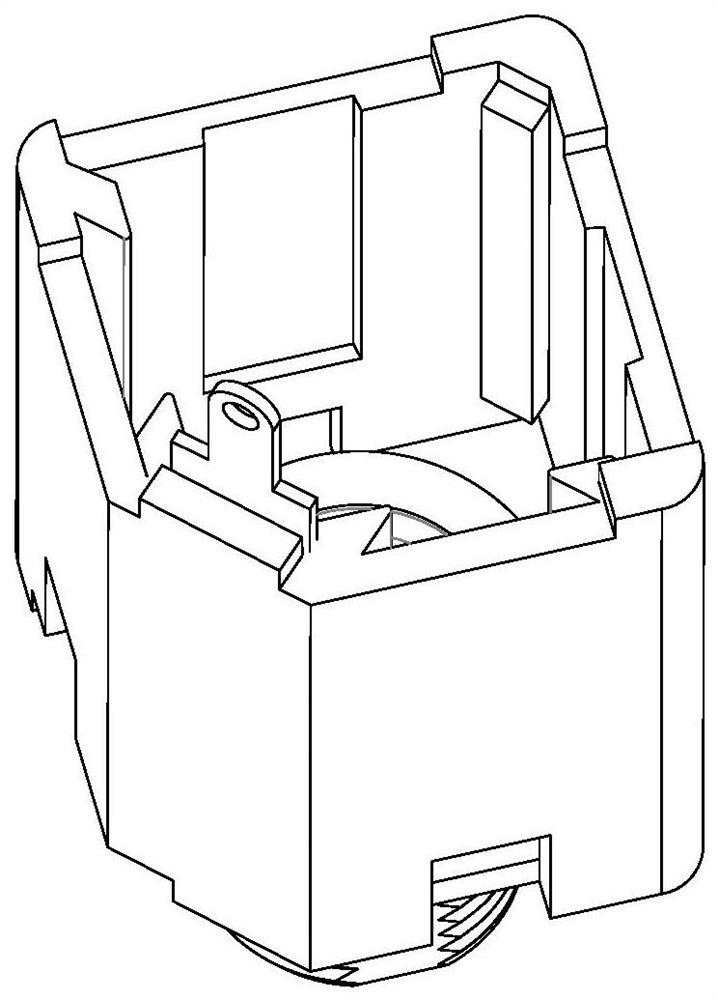

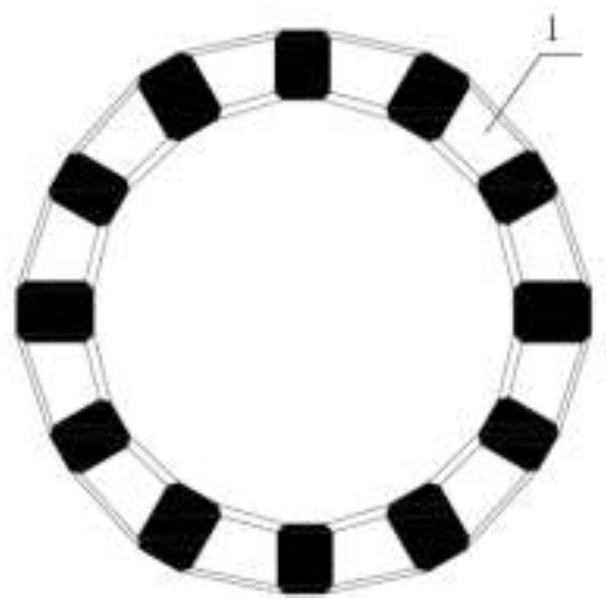

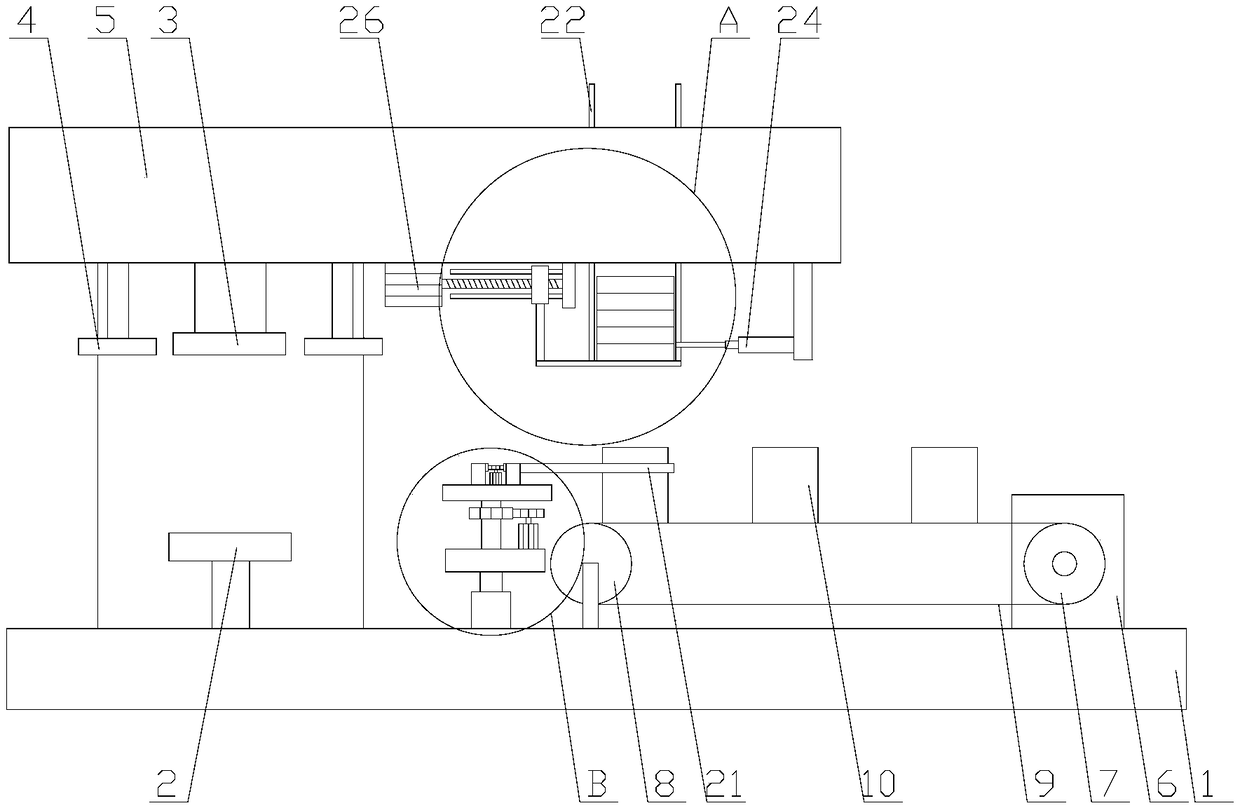

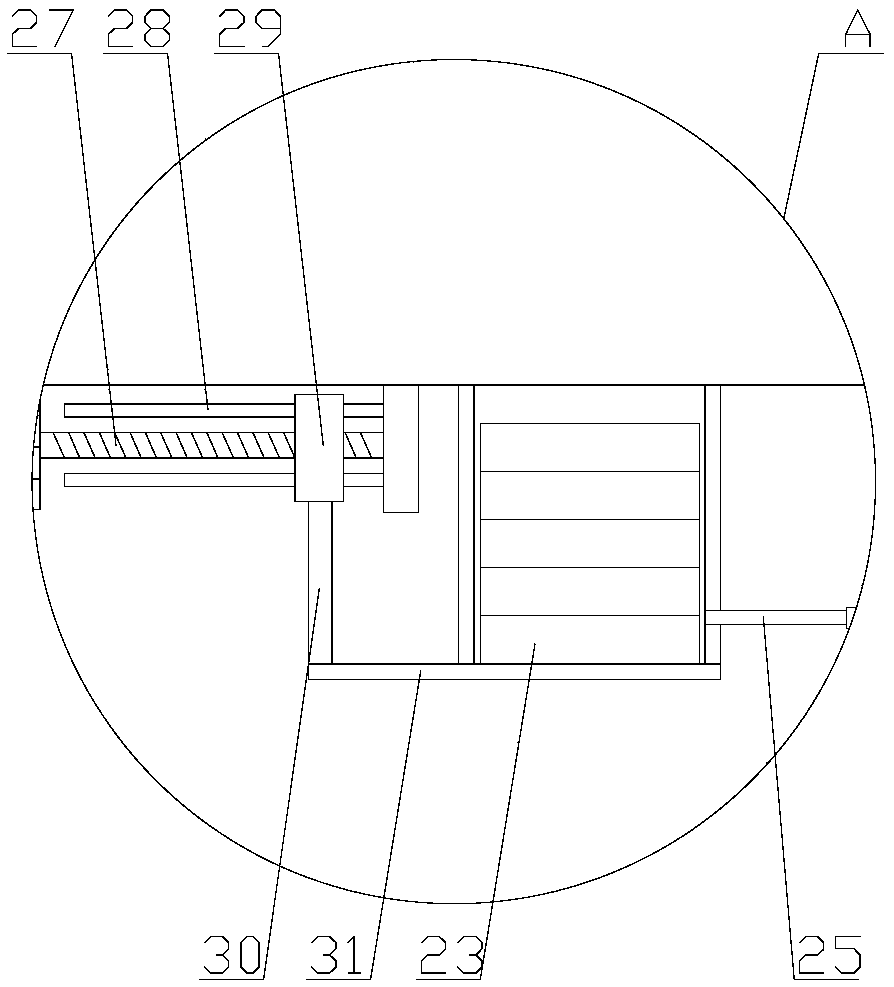

Audio jack assembly and inspection integrated machine

ActiveCN109746677AReduce work intensityIncrease productivityAssembly machinesFall detectionComputer engineering

The invention discloses an audio jack assembly and inspection integrated machine. The audio jack assembly and inspection integrated machine comprises a machine platform, and a rotating table is arranged on the machine platform. A plurality of positioning blocks are uniformly arranged on the upper end surface of the rotating table in the circumference direction, positioning grooves are formed in the upper end surfaces of the positioning blocks, and the shape of the positioning grooves is adapted to the shape of an audio jack. A loading device, a first insert piece feeding device, a second insert piece feeding device, a first press-fitting device, a third insert piece feeding device, a second press-fitting device, a fourth insert piece feeding device, a third press-fitting device and a material falling detection device are arranged in sequence near the machine platform, wherein the loading device, the first insert piece feeding device, the second insert piece feeding device, the third insert piece feeding device, and the fourth insert piece feeding device include circular shock devices, straight shock devices and cylinder grabbing feeding devices, and the material falling detection device includes a material grabbing device, a transfer device, a detection device and a waste grabbing and falling device. The audio jack assembly and inspection integrated machine has the advantages that the production efficiency of the audio jack is improved, and the production cost is reduced.

Owner:广东正宝科技有限公司

Process device for electroplating air valves

InactiveCN102912404ANot easy to damageReduce auxiliary timeElectrolysis componentsEngineeringElectroplating

The invention discloses a process device for electroplating air valves. The process device comprises an electroplating unit and is characterized in that a plurality of air valves are arranged on the electroplating unit, a fixing support is arranged above the electroplating unit and is movably connected with a cathode movable support through a turnover hinge, a locking pin which is fixedly connected with the fixing support is arranged on one side of the cathode movable support, a conductive clamping air cylinder is mounted on the cathode movable support, a plurality of piston rods are mounted on the conductive clamping air cylinder, conductive heads are arranged at the lower ends of the piston rods, and the positions of the conductive heads are above the air valves. The process device for electroplating air valves has the advantages that the conductive clamping air cylinder is not easy to damage, and the production efficiency is improved; the maintenance time is reduced, so that the device utilization rate and the device perfectness ratio are improved; as the conductive heads are turned upward, cleaning is facilitated, and effects on the production efficiency as the conduction of the conductive heads is poor are avoided; and the auxiliary time of electroplating armoring is decreased.

Owner:鹰普航空科技(南通)有限公司

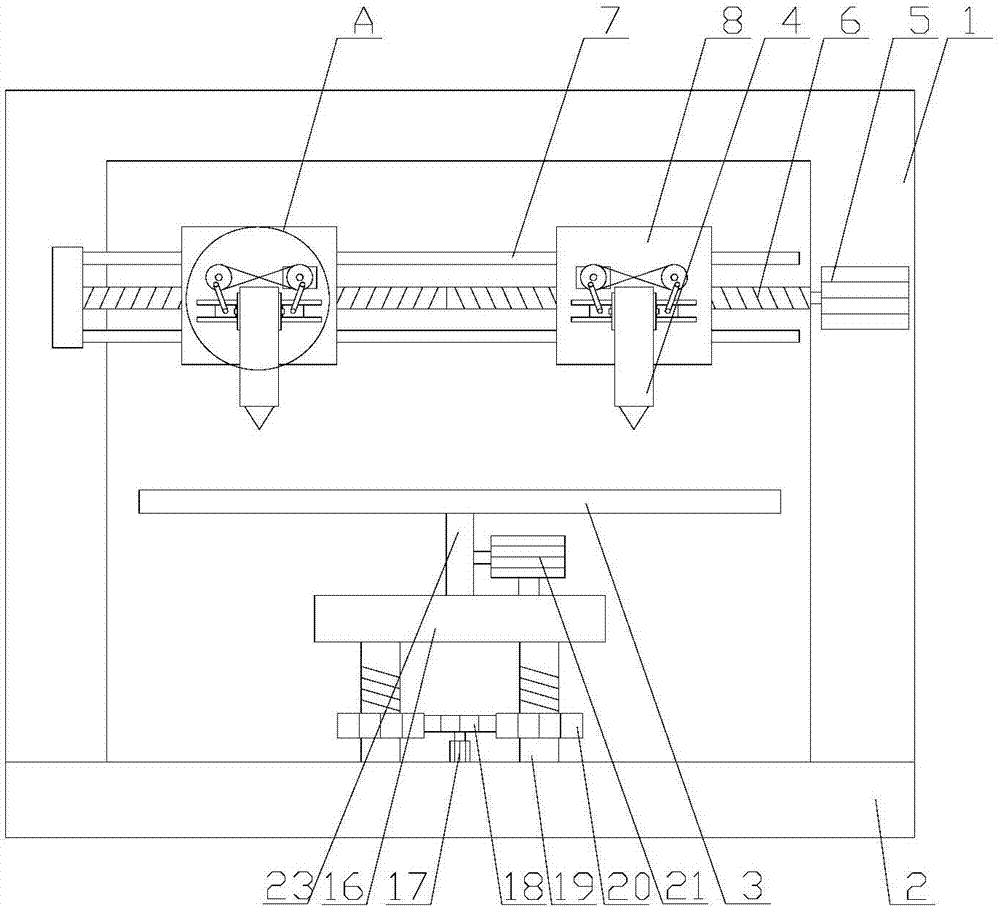

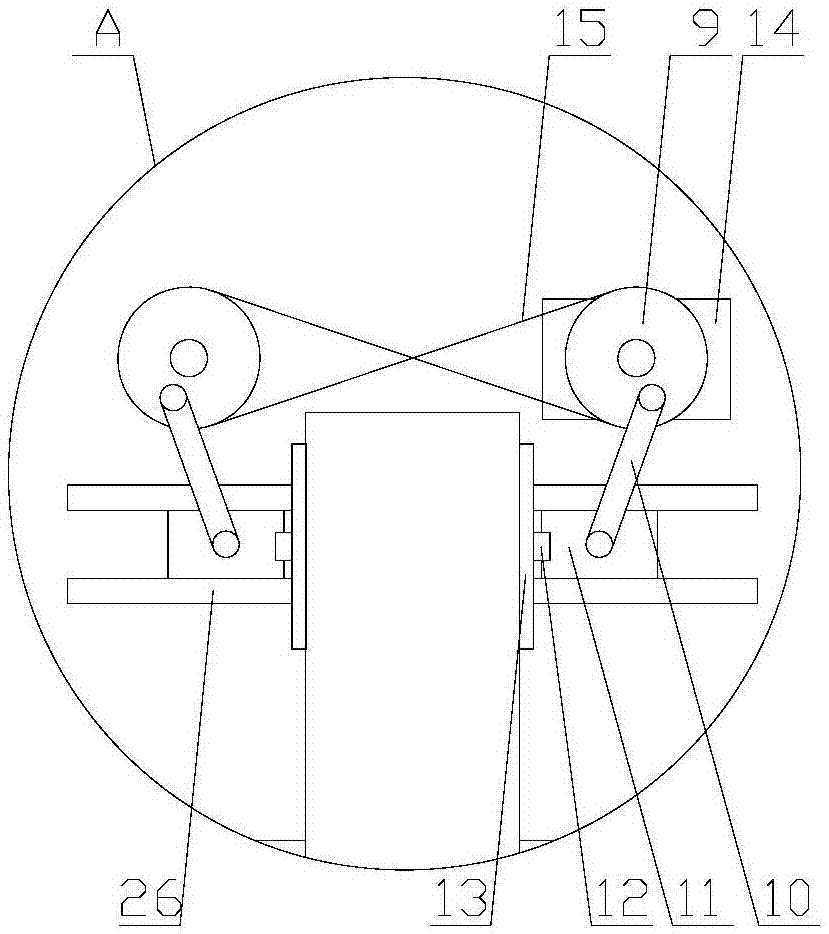

Intelligent plasma cutting machine based on Internet of Things

InactiveCN107378213AImprove reliabilityMeet collectionPlasma welding apparatusSignal processing circuitsDrive motor

The invention relates to an intelligent plasma cutting machine based on the Internet of Things, including a base, a cutting table, a cutting bridge and a cutting head, the cutting bridge also includes a clamping mechanism, the base also includes a sealing mechanism, and the clamping mechanism includes a drive motor and a drive plate , a fixed plate and a clamping assembly, the clamping assembly includes several clamping units, the clamping unit includes a drive block, a connecting block and a clamping block, the intelligent plasma cutting machine based on the Internet of Things, the cutting bridge is equipped with a clamping When the cutting machine is working normally, the clamping mechanism can clamp and fix the cutting head. When the cutting head needs to be replaced and maintained, the cutting head can be removed from the clamping mechanism without disassembly, which not only saves time and effort, but also reduces the labor intensity, and avoid the impact on production efficiency; in addition, the signal processing circuit has the function of adjustable gain, which can meet the collection of input signals of different levels, and improves the reliability of the signal processing circuit.

Owner:时伟

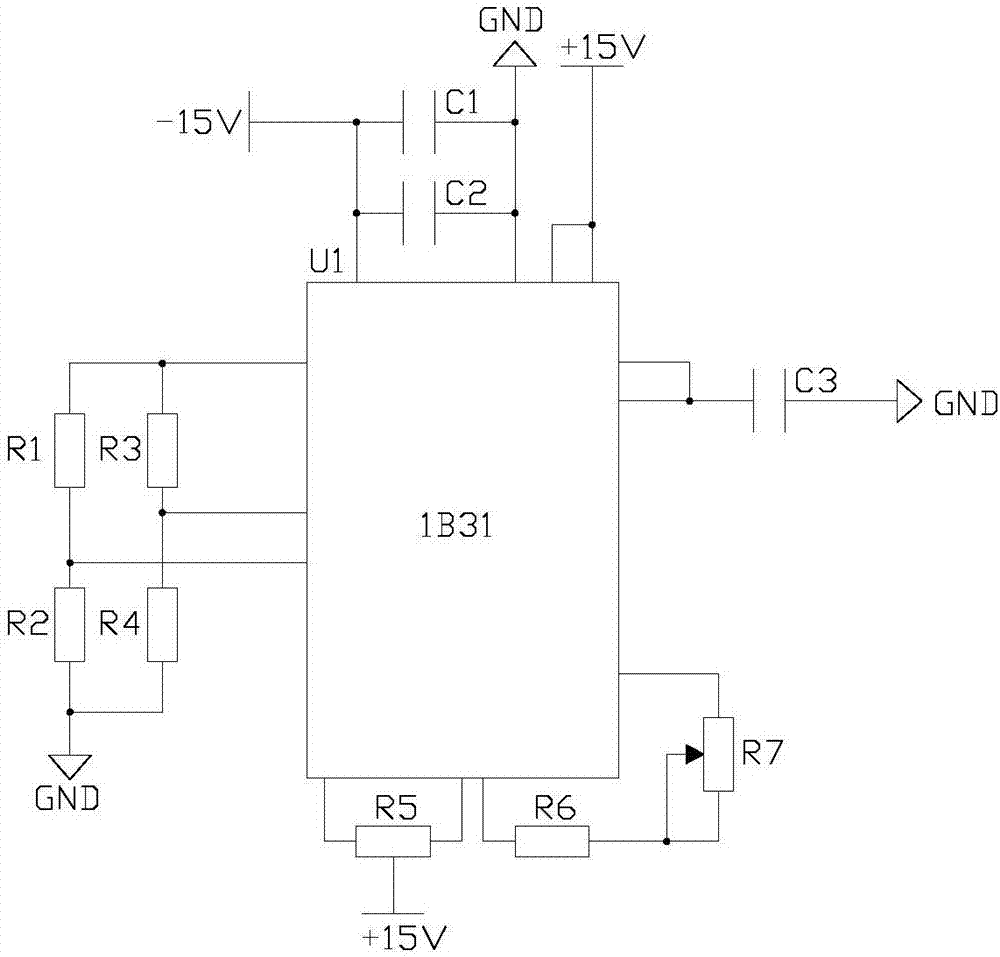

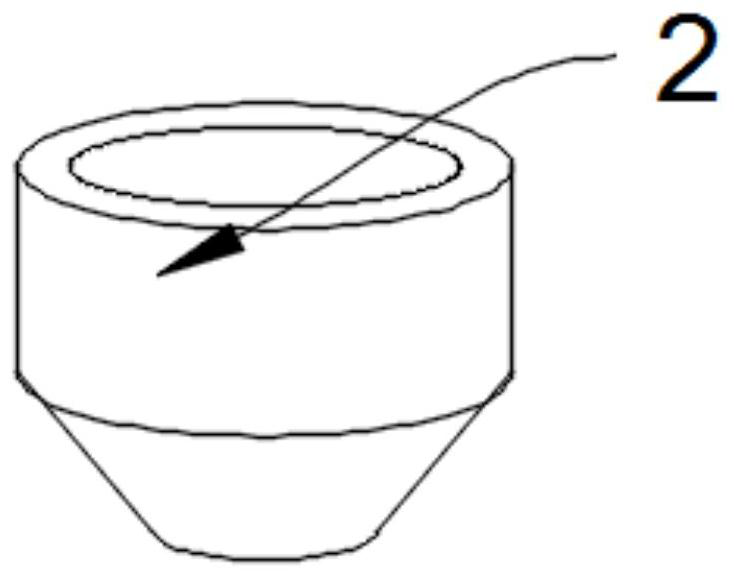

Beverage can sealing machine based on internet of things

InactiveCN107512414AReduce labor intensityAvoid affecting productivityPackaging automatic controlShort circuit protectionSpeech control

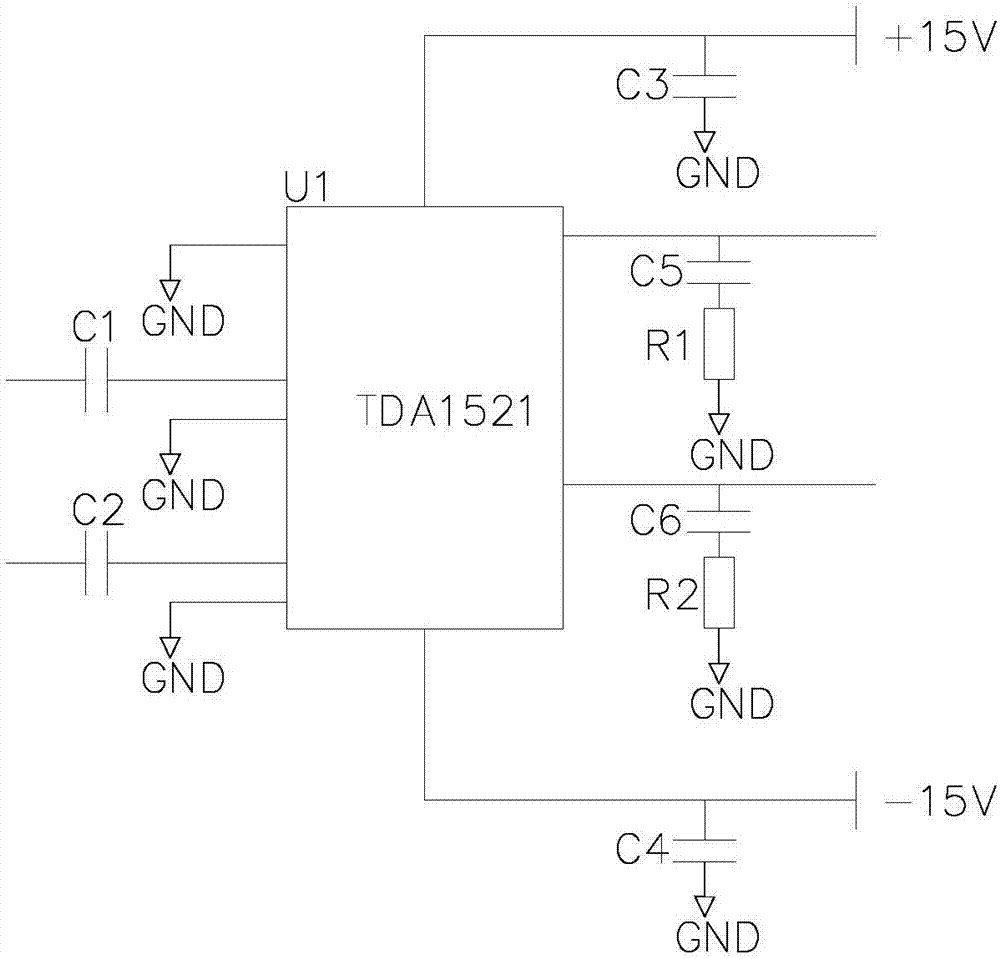

The invention relates to a can sealing machine based on the Internet of Things, which includes a chassis, a tray, a press head, a hob and a driving chamber. The chassis also includes a voice control module and a feeding mechanism, and the driving chamber also includes a capping mechanism. The mechanism includes a lifting assembly, a rotating assembly and a clamping assembly. The capping mechanism includes a storage cap tube, a tank cover, a support assembly and a capping assembly. The support assembly includes a second cylinder and a support plate. The capping assembly includes a fourth motor and a screw rod. , sliding rods, sliders, connecting rods and shielding plates, this can sealing machine based on the Internet of Things, compared with manual operation, this method is relatively time-saving and labor-saving, which not only reduces the labor intensity of workers, but also avoids affecting production efficiency. In the voice control circuit, the type of integrated circuit U1 is TDA1521, which has a large output power, which ensures the reliability of the voice signal output, and has the function of overheating, overload and short circuit protection, thereby improving the reliability of the system.

Owner:时伟

Injection blowing hollow forming device

The invention discloses an injection blowing hollow forming device. The device comprises a device mounting shell; a feeding and stirring mechanism is arranged on the device mounting shell and comprises a feeding hopper; a stirring chamber is arranged below the feeding hopper and communicates with the feeding hopper; stirring rods are symmetrically arranged in the stirring chamber; stirring blades are symmetrically arranged on the peripheries of the stirring rods; the stirring blades are connected with the stirring rods; driven gears are symmetrically arranged below the stirring rods; the stirring rods penetrate through the driven gears; a driving gear is arranged on one side of each driven gear; and the driving gears mesh with the driven gears. The device is high in automation degree and production efficiency, can meet the requirement for production of large-batch bottles, and greatly solves the technical problems that the produced bottles cannot be effectively and quickly demoulded, the production efficiency of the bottles is influenced and the like.

Owner:广东逢春塑料包装有限公司

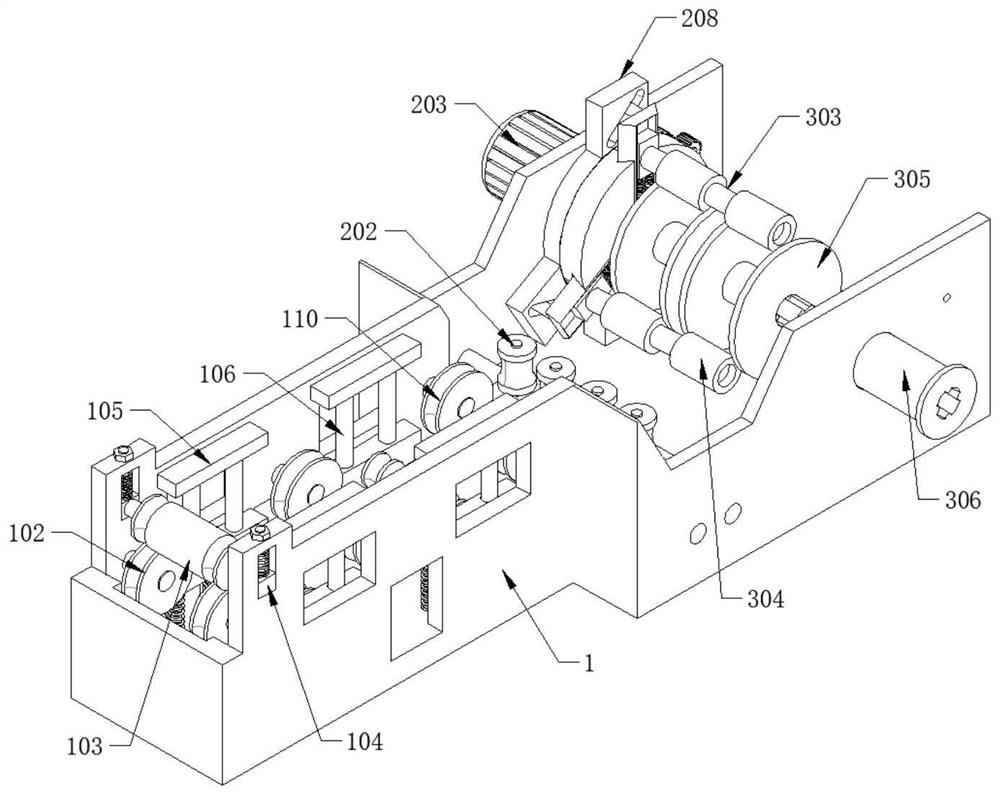

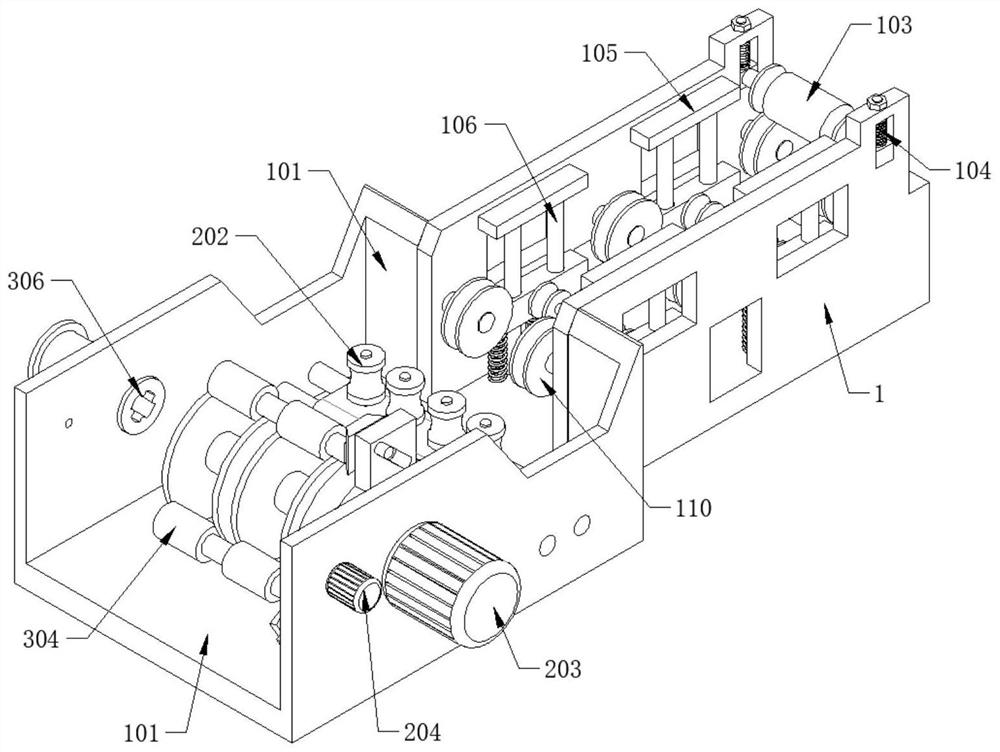

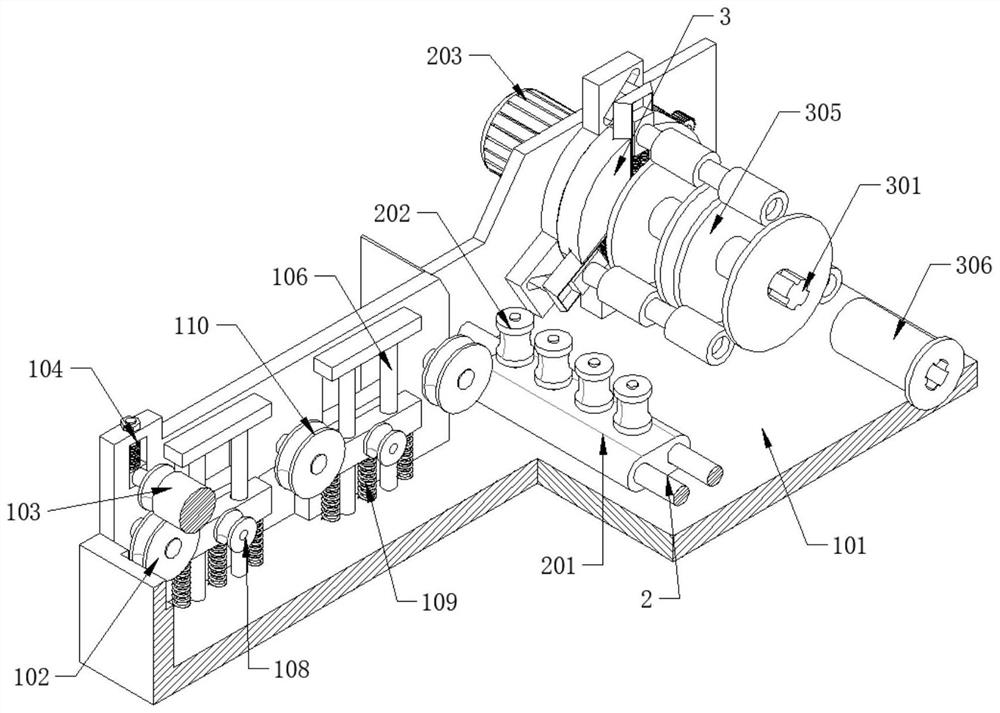

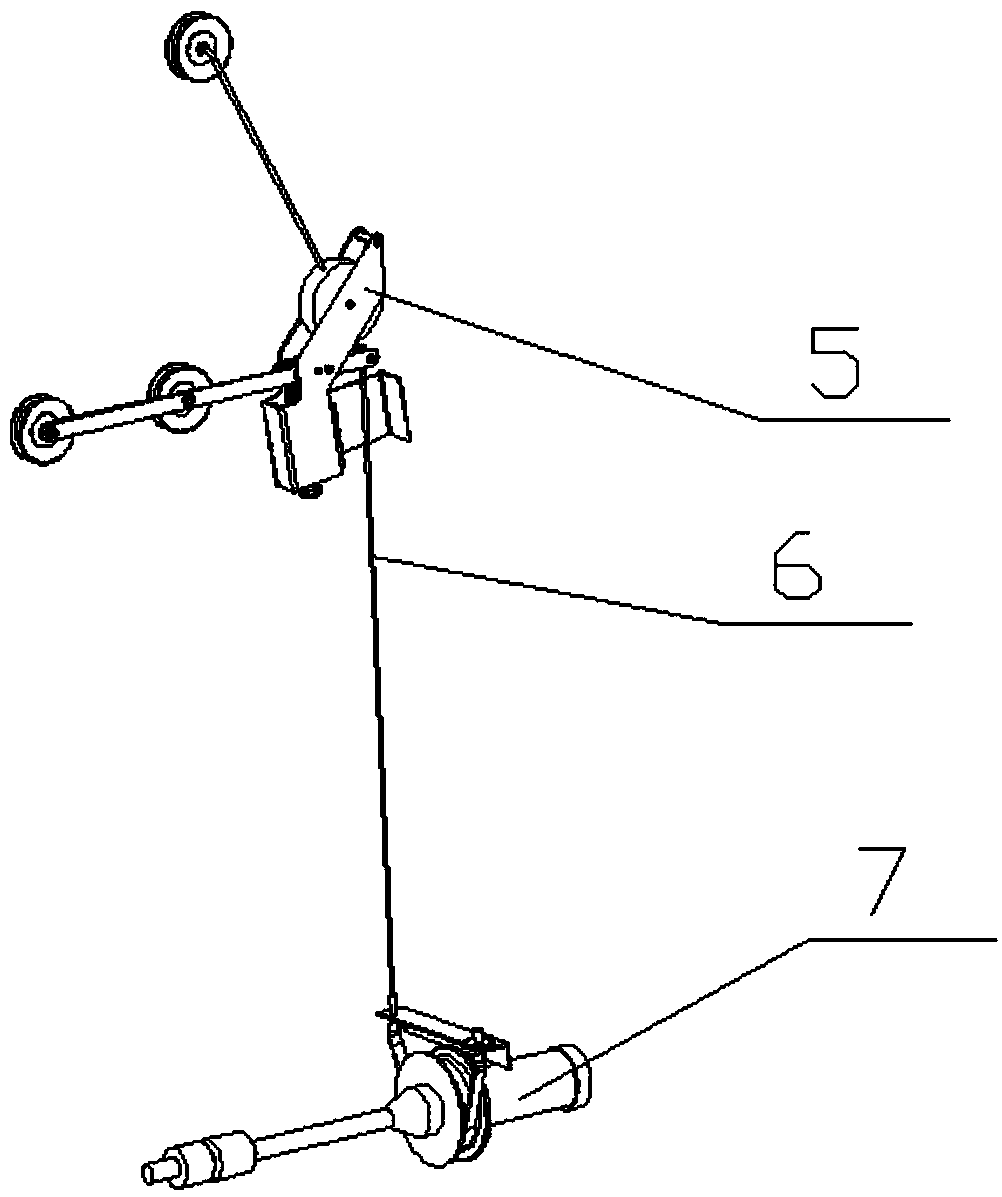

Protection mechanism for wire coiling device of wire extruder and using method thereof

The invention discloses a protection mechanism for a wire coiling device of a wire extruder and a using method thereof, and belongs to the technical field of wire extruders. The protection mechanism for the wire coiling device of the wire extruder comprises a base and a shell, a tension control mechanism comprises a first elastic assembly and a second elastic assembly, a fixed plate is fixed to the inner wall of the shell, a sliding column is connected to the bottom of the fixed plate, the other end of the sliding column is connected to the top of the base, and the outer wall of the sliding column is slidably connected with a first sliding block; and the outer wall of the first sliding block is rotationally connected with a movable roller, two or three groups of springs are connected between the bottom of the first sliding block and the top of the base, and two groups of tension control mechanisms are symmetrically arranged. According to the protection mechanism, by adjusting the tension of a wound electric wire, the situation that the electric wire is accidentally broken in the winding process is greatly reduced, and the problem that after the electric wire is broken, the electric wire and the whole equipment are damaged due to high-speed rotation can be solved through a clamping mechanism.

Owner:廉江市通力电器有限公司

Water cooling mechanism for producing medical PVC plastic particles

PendingCN111823440AImprove work efficiencyAvoid the impact of production efficiencyElectric machineryPhysics

The invention relates to the technical field of water cooling mechanisms, and discloses a water cooling mechanism for producing medical PVC plastic particles. The water cooling mechanism for producingmedical PVC plastic particles comprises a working box, two supporting plates are symmetrically and fixedly connected to the inner wall of the lower side of the working box, the two supporting platesare rotationally connected with the same net barrel through bearings, a feeding port is formed in the side wall of the working box, a feeding hopper is fixedly connected into the feeding port, the end, located in the working box, of the feeding hopper extends into the net barrel, a discharging port is formed in the side wall, away from the feeding port, of the working box, the side wall, away fromthe feeding hopper, of the net barrel is rotationally connected with the side wall of the discharging port through bearings, a hoop is fixedly connected to the barrel wall of the net barrel, and a driving motor is fixedly connected to the inner wall of the upper side of the working box. According to the water cooling mechanism for producing medical PVC plastic particles, plastic particles can becollected in a centralized mode after being cooled, the working efficiency of operators is improved, the plastic particles can be collected in a centralized mode after being cooled, and the working efficiency of the operators is improved.

Owner:高邮市汉升高分子材料有限公司

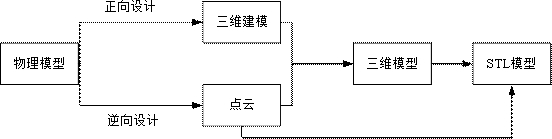

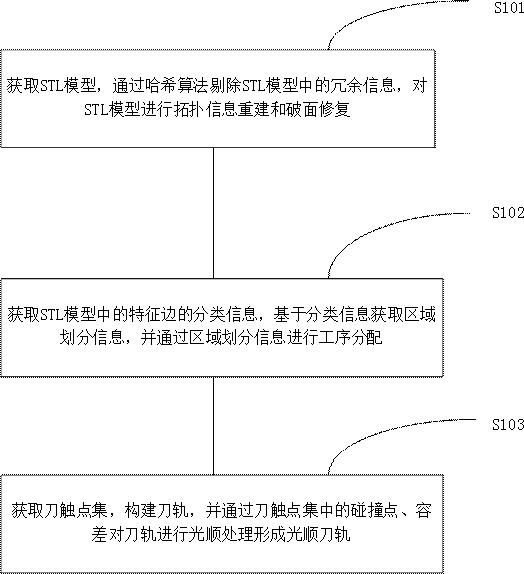

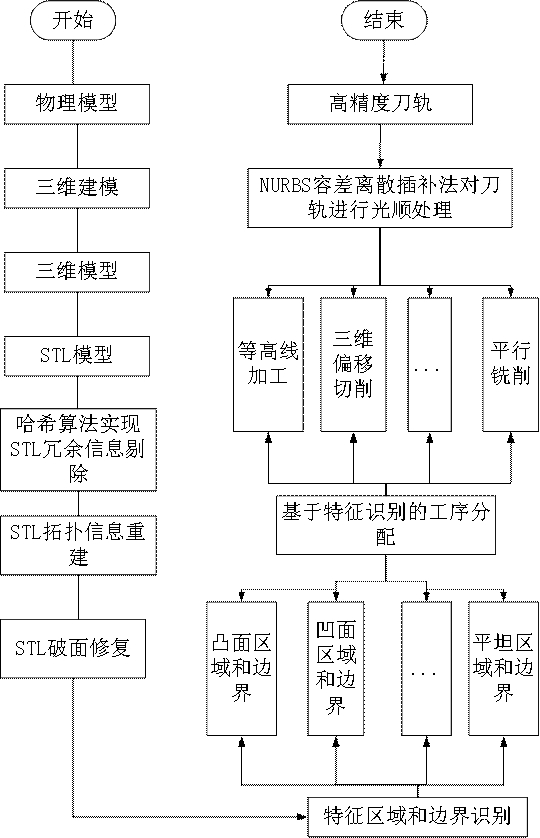

STL model-based tool path generation method, intelligent terminal and storage device

ActiveCN113204213AHigh precisionImprove efficiencyProgramme controlComputer controlTopology informationAlgorithm

The invention provides an STL model-based tool path generation method, an intelligent terminal and a storage device. The generation method comprises the following steps: S101, obtaining an STL model, eliminating redundant information in the STL model through a Hash algorithm, and carrying out the topological information reconstruction and broken surface repair of the STL model; S102, obtaining region division information according to the classification information of the feature edges in the STL model, and carrying out process distribution through the region division information; and S103, obtaining a tool contact point set, constructing a tool path, and carrying out fairing processing on the tool path through collision points and tolerances in the tool contact point set to form a fairing tool path. The precision and efficiency of imported data are improved, the problem of tool path generation failure is reduced, the optimal procedure of importing model features and allocating corresponding features is automatically identified, the actual machining efficiency and the machining quality are improved, the influence of complex calculation curves on the tool path generation efficiency is avoided, and the tool path precision is improved by performing fairing processing on the tool path..

Owner:ZWCAD SOFTWARE CO LTD

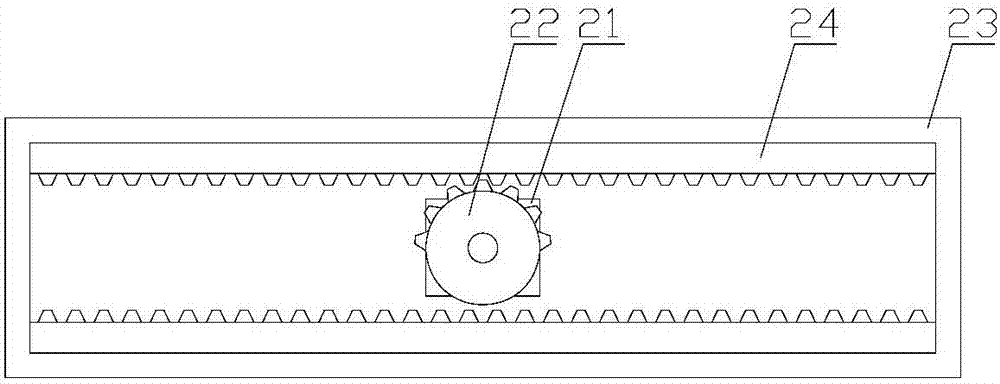

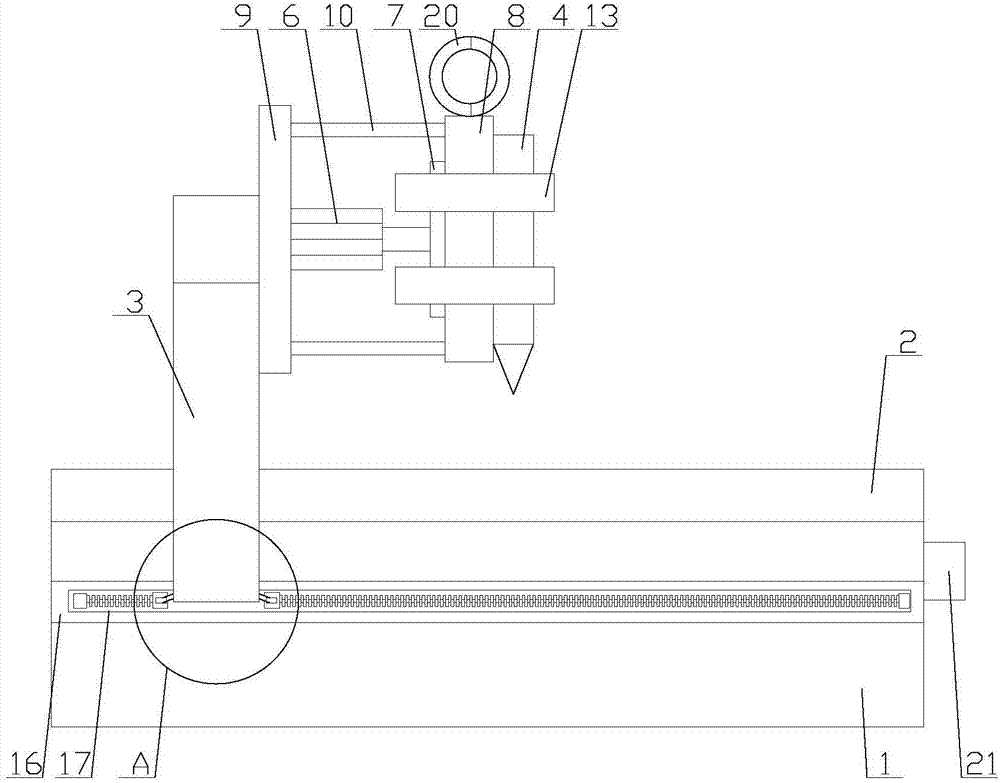

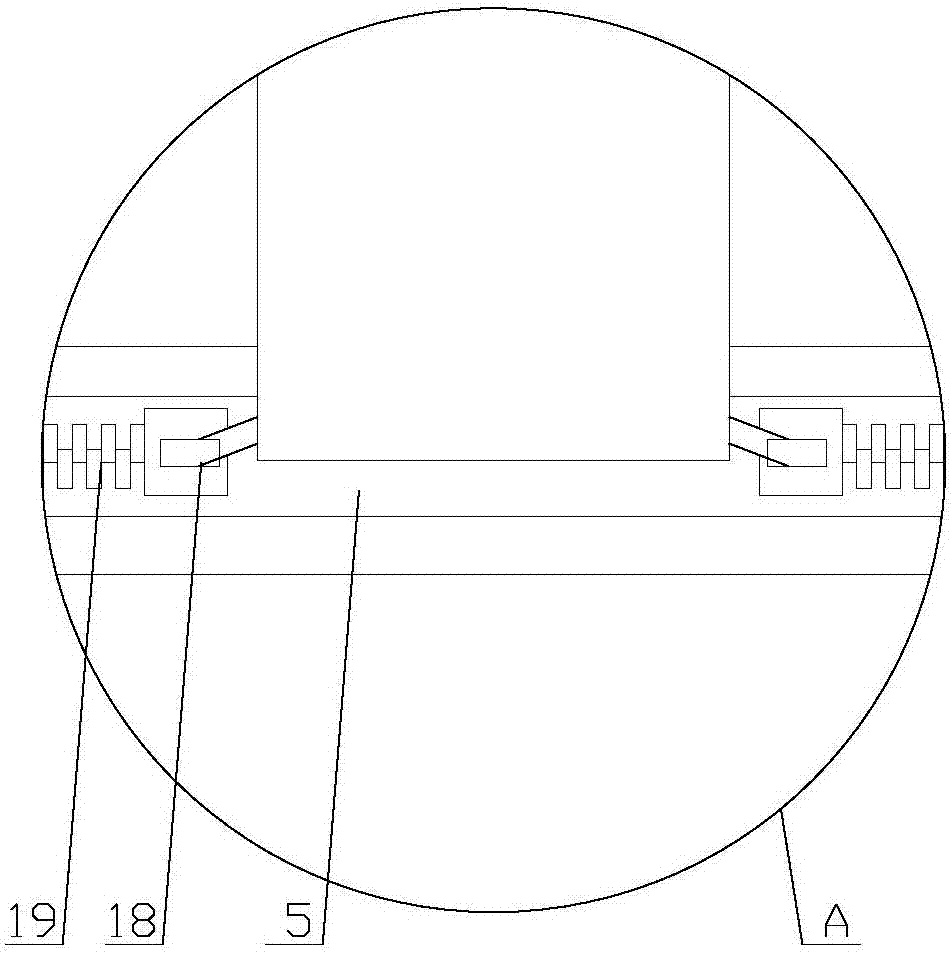

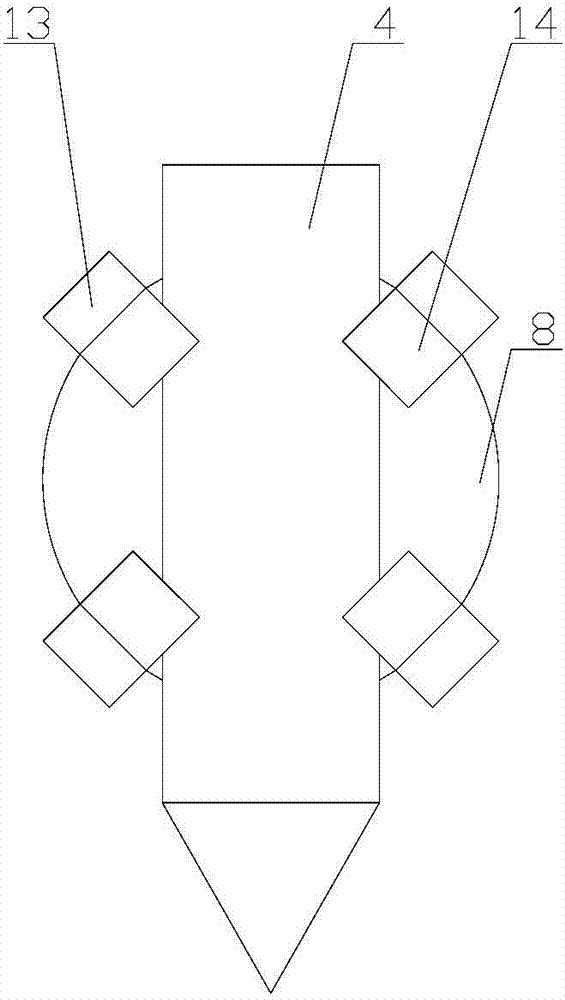

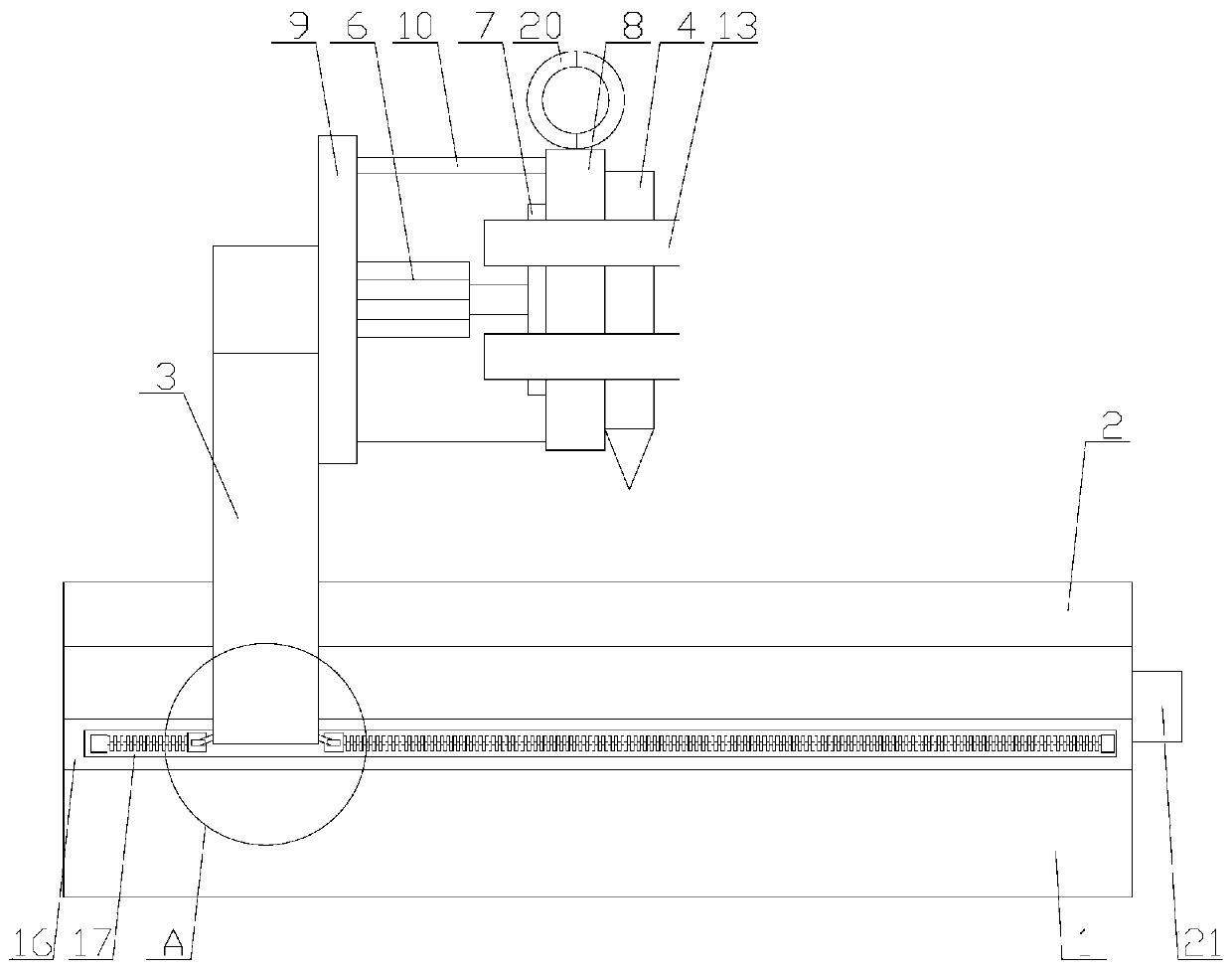

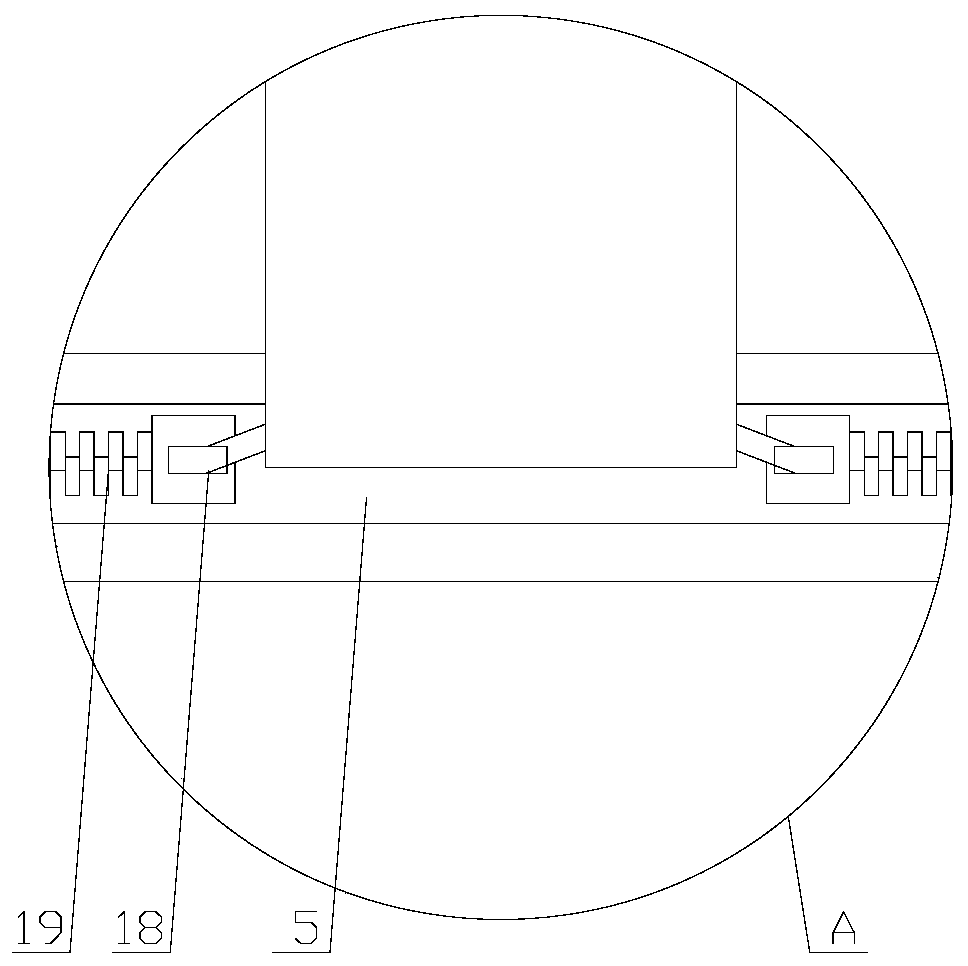

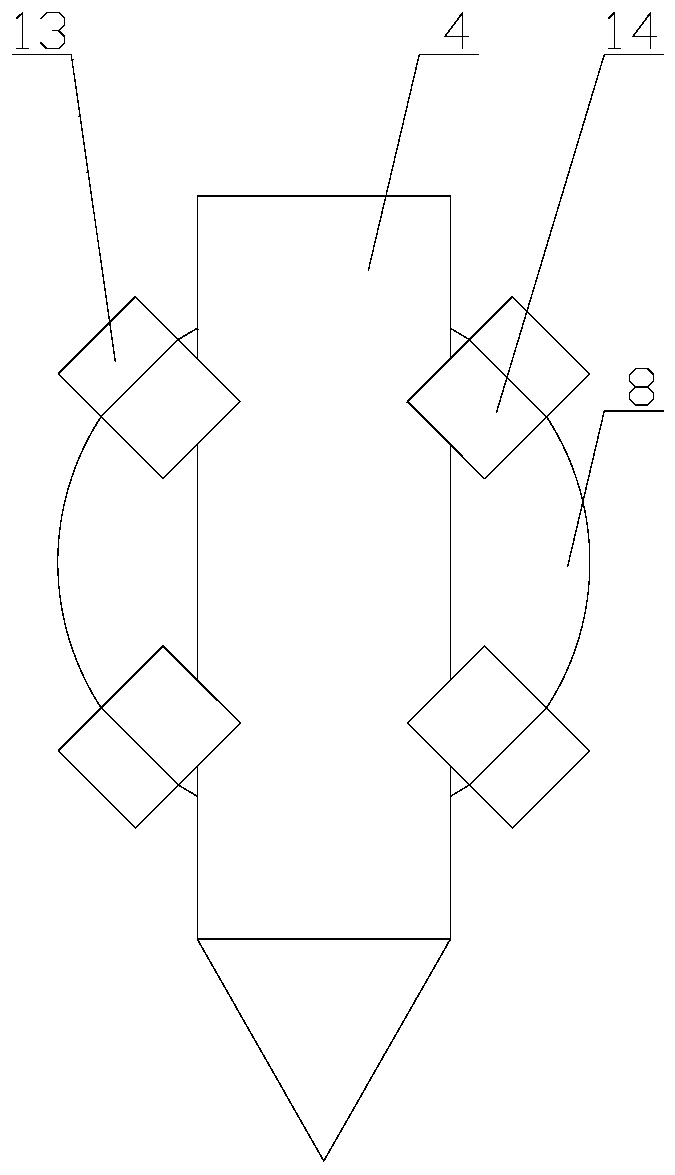

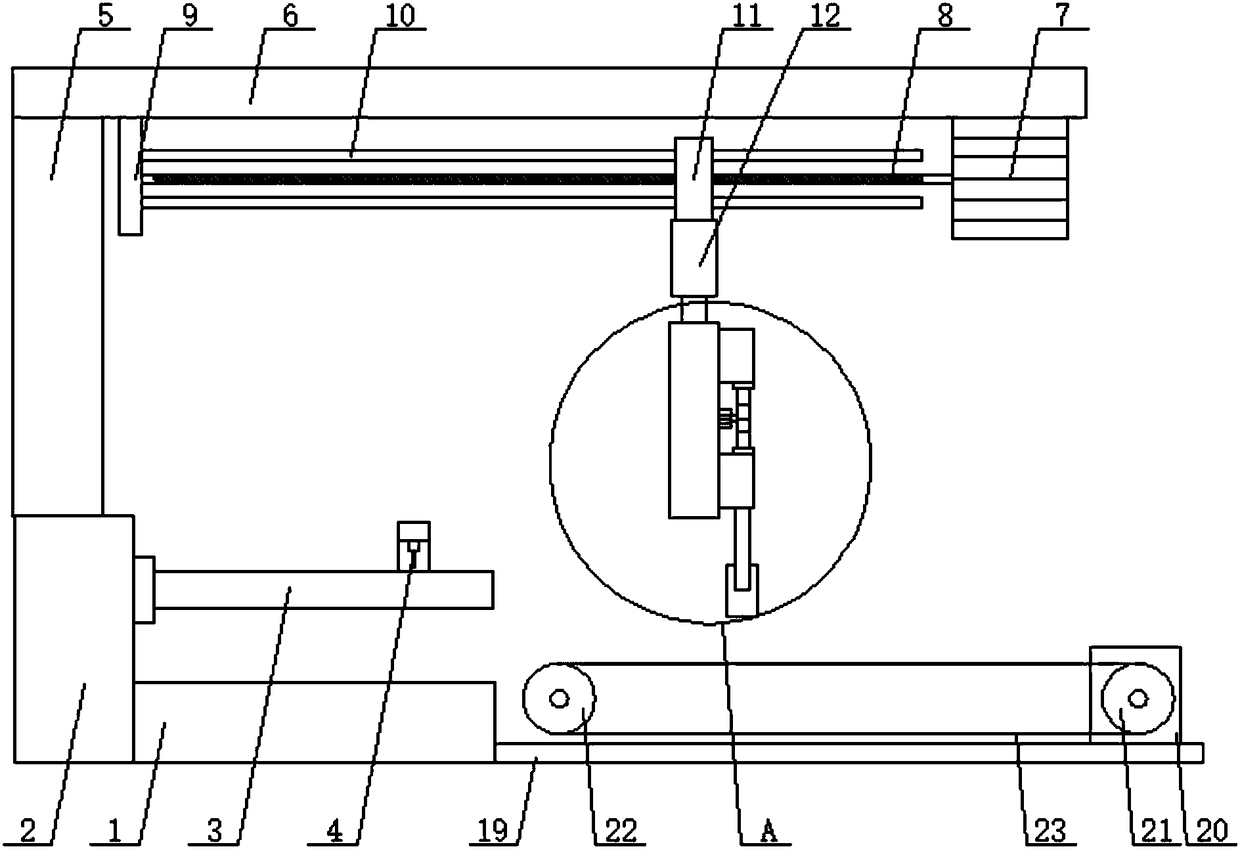

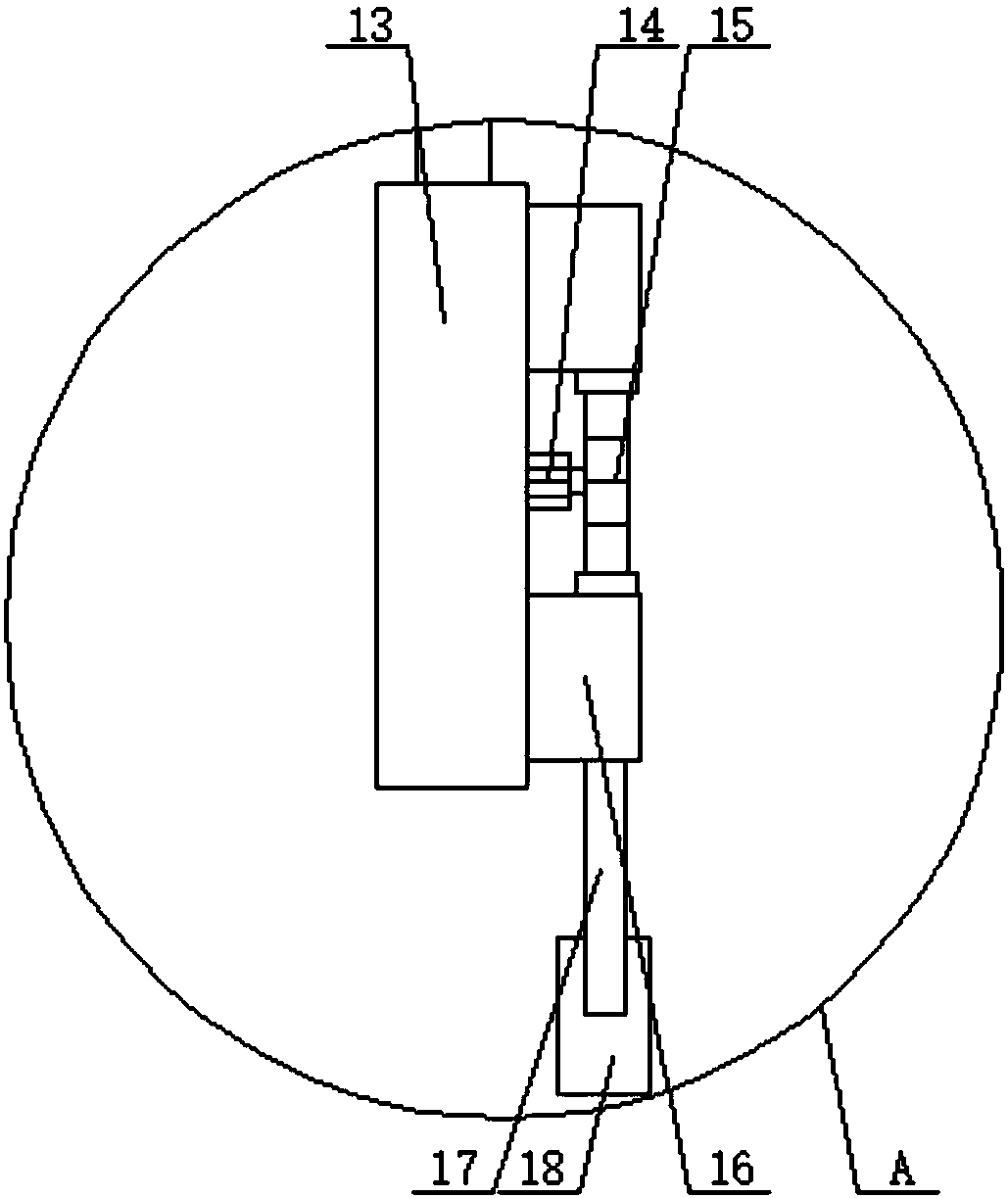

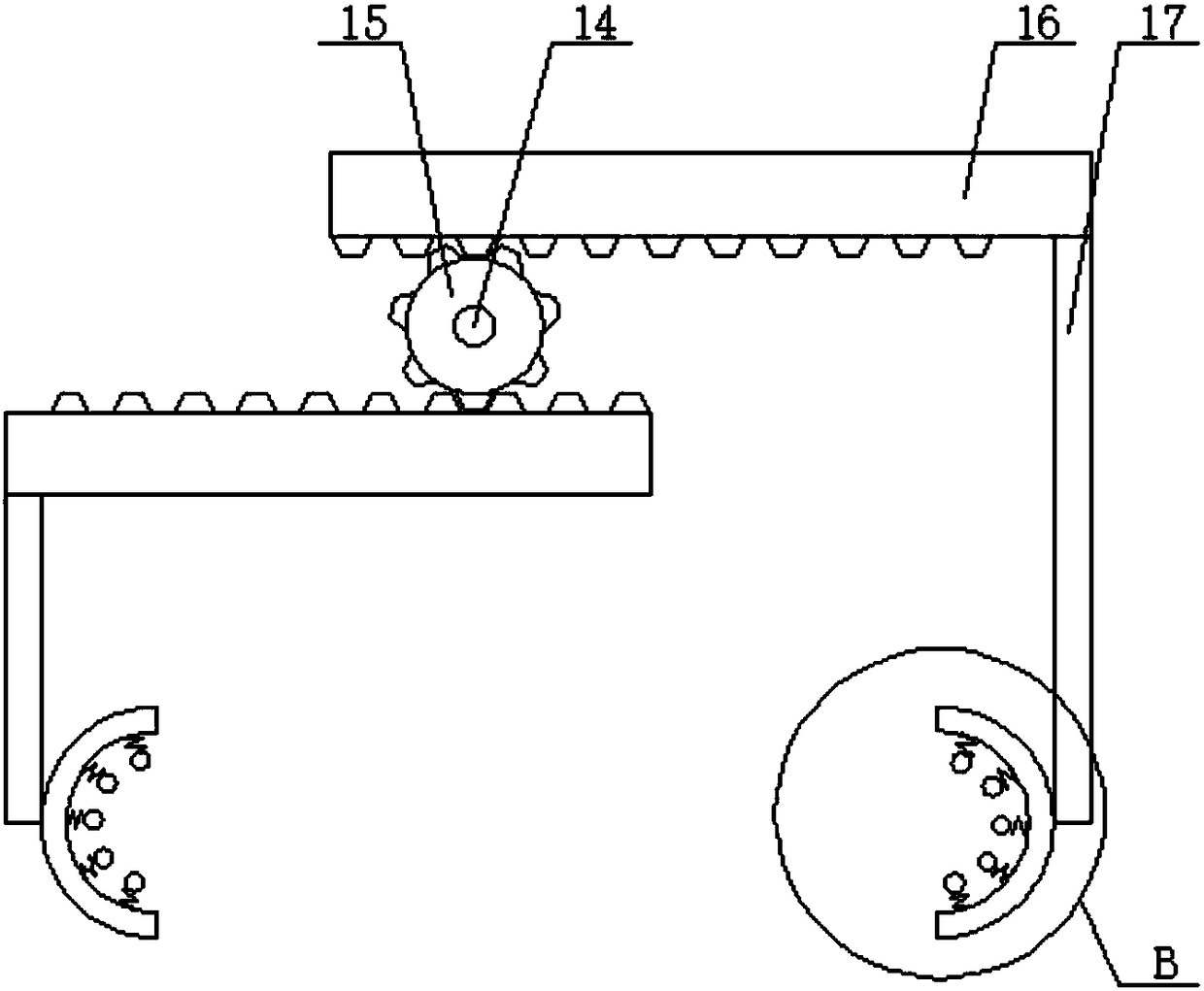

Intelligent plasma cutting machine

ActiveCN107138835AGuaranteed normal slidingReduce labor intensityPlasma welding apparatusEngineeringDrive motor

The invention relates to an intelligent plasma cutting machine. The intelligent plasma cutting machine comprises a base, a cutting table, a cutting bridge and a cutting head; the cutting bridge further comprises a clamping mechanism; the base further comprises a sealing mechanism; the clamping mechanism comprises a driving motor, a driving plate, a fixing plate and a clamping assembly; the clamping assembly comprises a plurality of clamping units; the clamping units comprise driving blocks, connecting blocks and clamping blocks; and the sealing mechanism comprises a sealing cover, a chain belt and pulling heads. According to the intelligent plasma cutting machine, the clamping mechanism is arranged on the cutting bridge, when the cutting machine works normally, the clamping mechanism can clamp and fix the cutting head, when the cutting head needs to be replaced and maintained, the cutting head can be taken down from the clamping mechanism, disassembly is not needed, and therefore time and labor can be saved, the labor intensity can be relieved, and the influence on the production efficiency can also be avoided; and in addition, a sliding rail is sealed and protected through the sealing mechanism so that the phenomenon that the sliding rail is corroded due to long-term exposure to air can be avoided, and therefore normal sliding of the cutting bridge can be guaranteed.

Owner:青岛鼎盛源钢结构有限公司

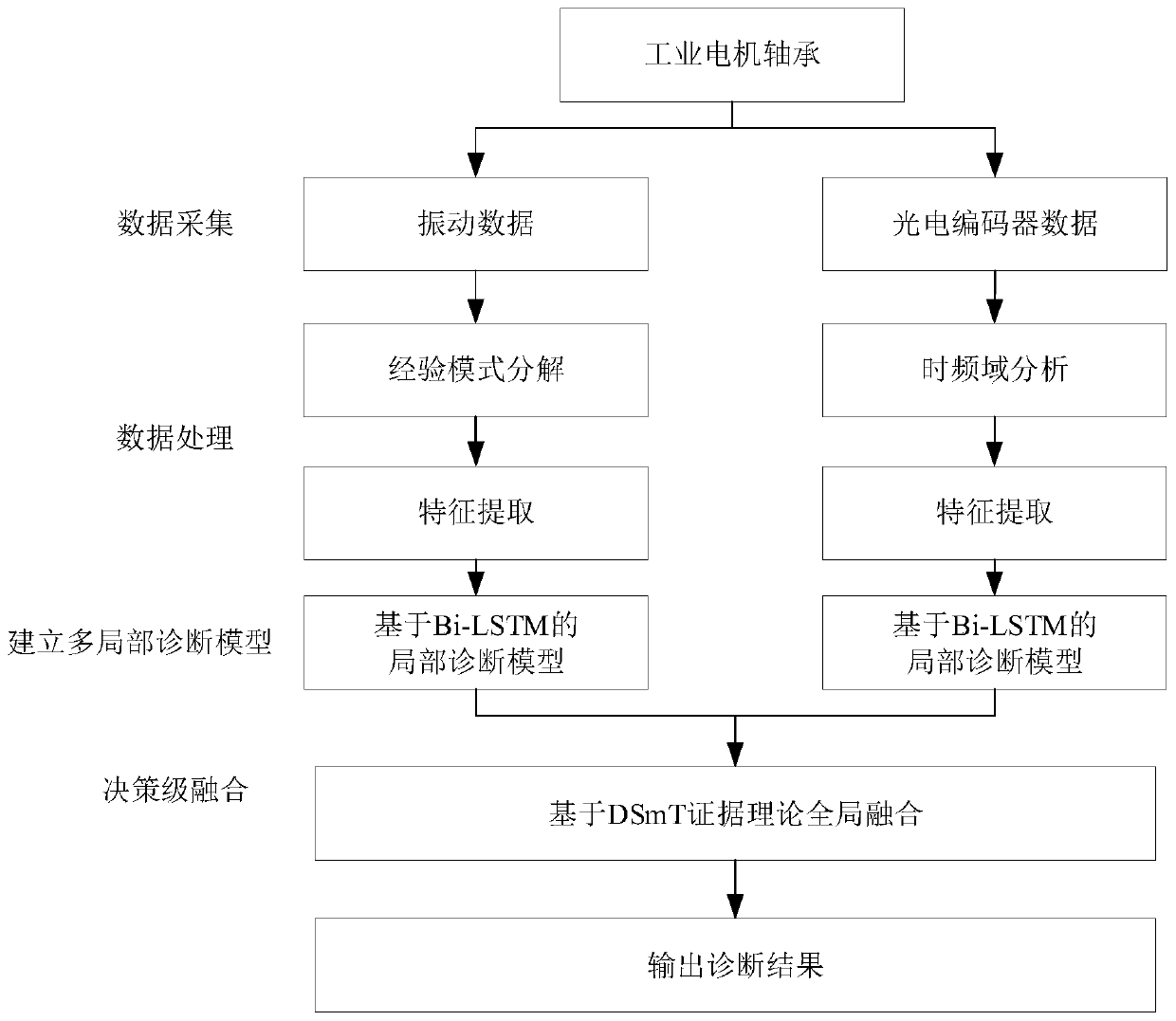

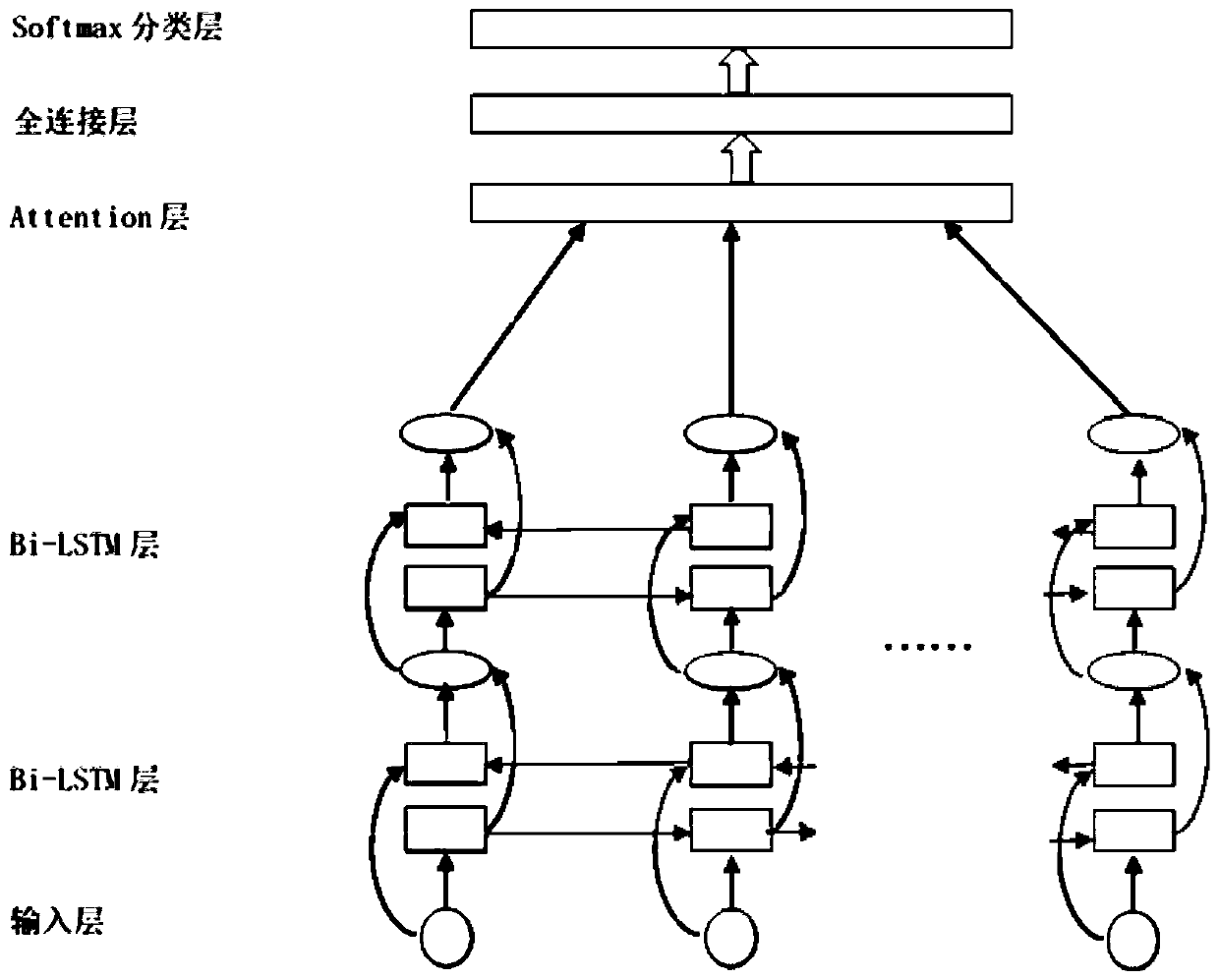

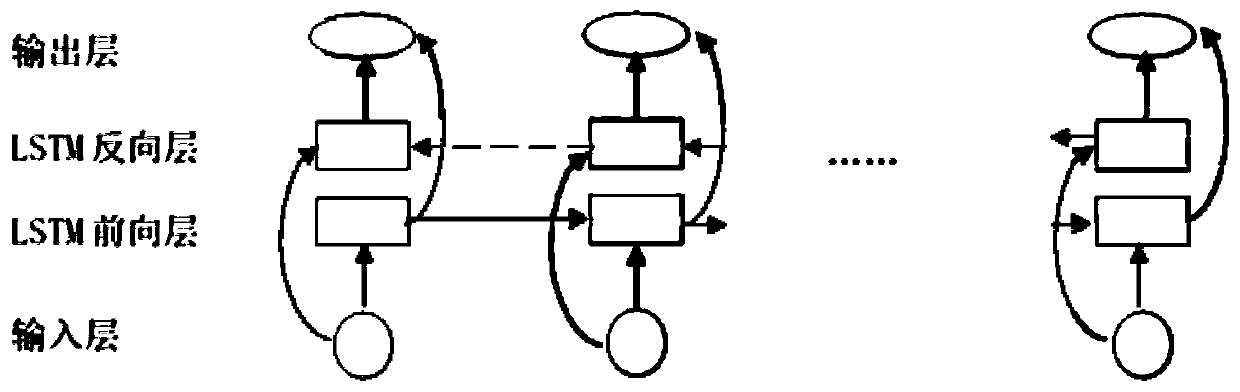

Industrial motor bearing fault diagnosis method based on multi-local-model decision fusion

ActiveCN111380687AComprehensive mechanical informationAvoid the impact of production efficiencyMachine part testingFeature extractionData acquisition

The invention discloses an industrial motor bearing fault diagnosis method based on multi-local-model decision fusion. The method comprises the four steps: data collection, data processing, building of multiple local diagnosis models, and decision-level fusion. In the step of data collection, two different types of sensors are employed to collect the related data of a motor bearing. In the step ofdata processing, preprocessing and feature extraction are performed on the two kinds of collected data. In the step of building of multiple local diagnosis models, local diagnosis models for the twokinds of processed data are built based on a Bi-LSTM neural network. In the step of decision-level fusion, decision-level fusion is performed on the local diagnosis results output by the two local diagnosis models based on the DSmT theory to obtain a final diagnosis result. According to the industrial motor bearing fault diagnosis method designed by the invention, a factory can be better helped tofind motor faults caused by bearing damage timely and accurately, and the influence on motor operation and factory production efficiency due to shutdown is avoided to a certain extent.

Owner:HOHAI UNIV CHANGZHOU

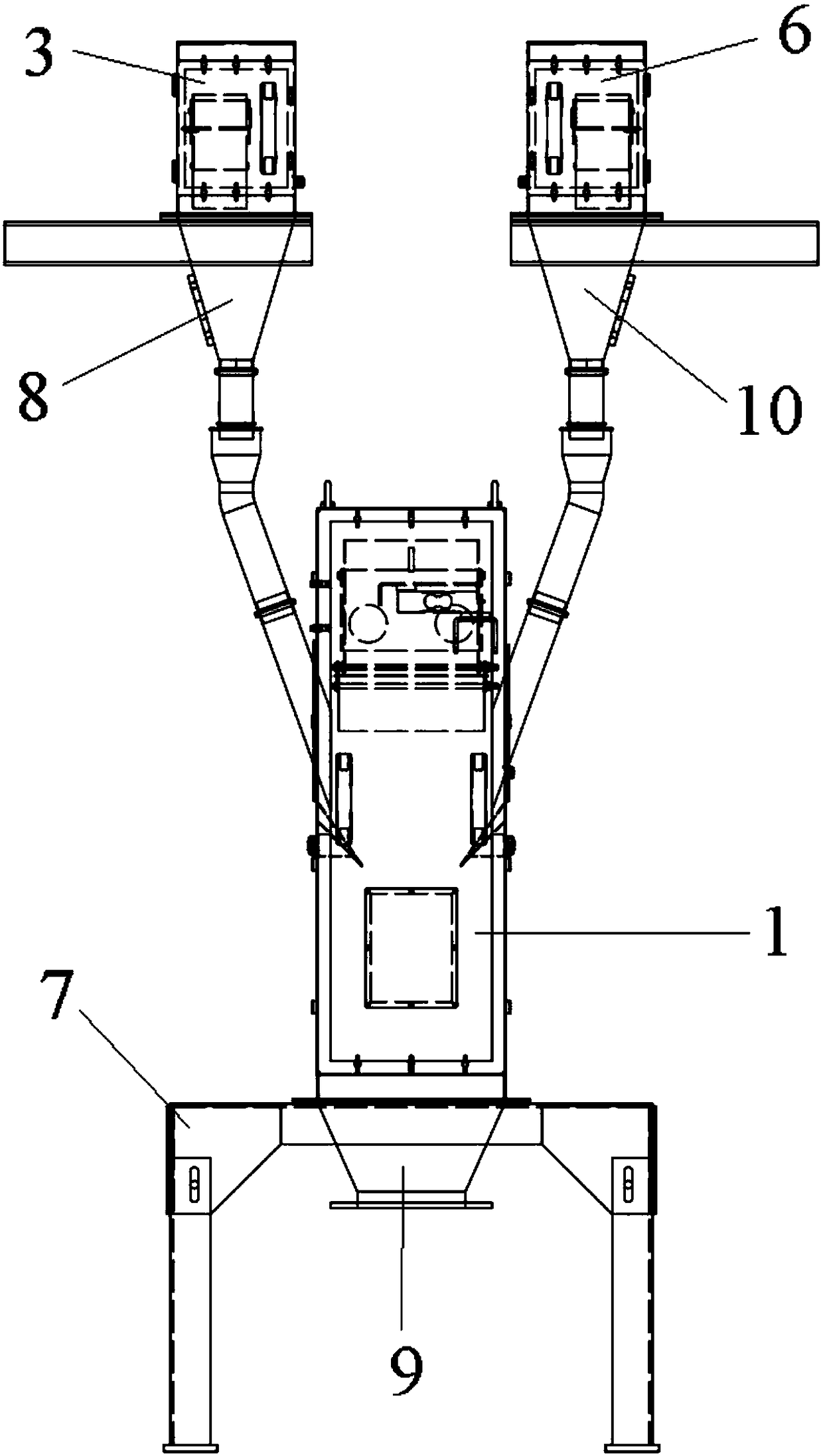

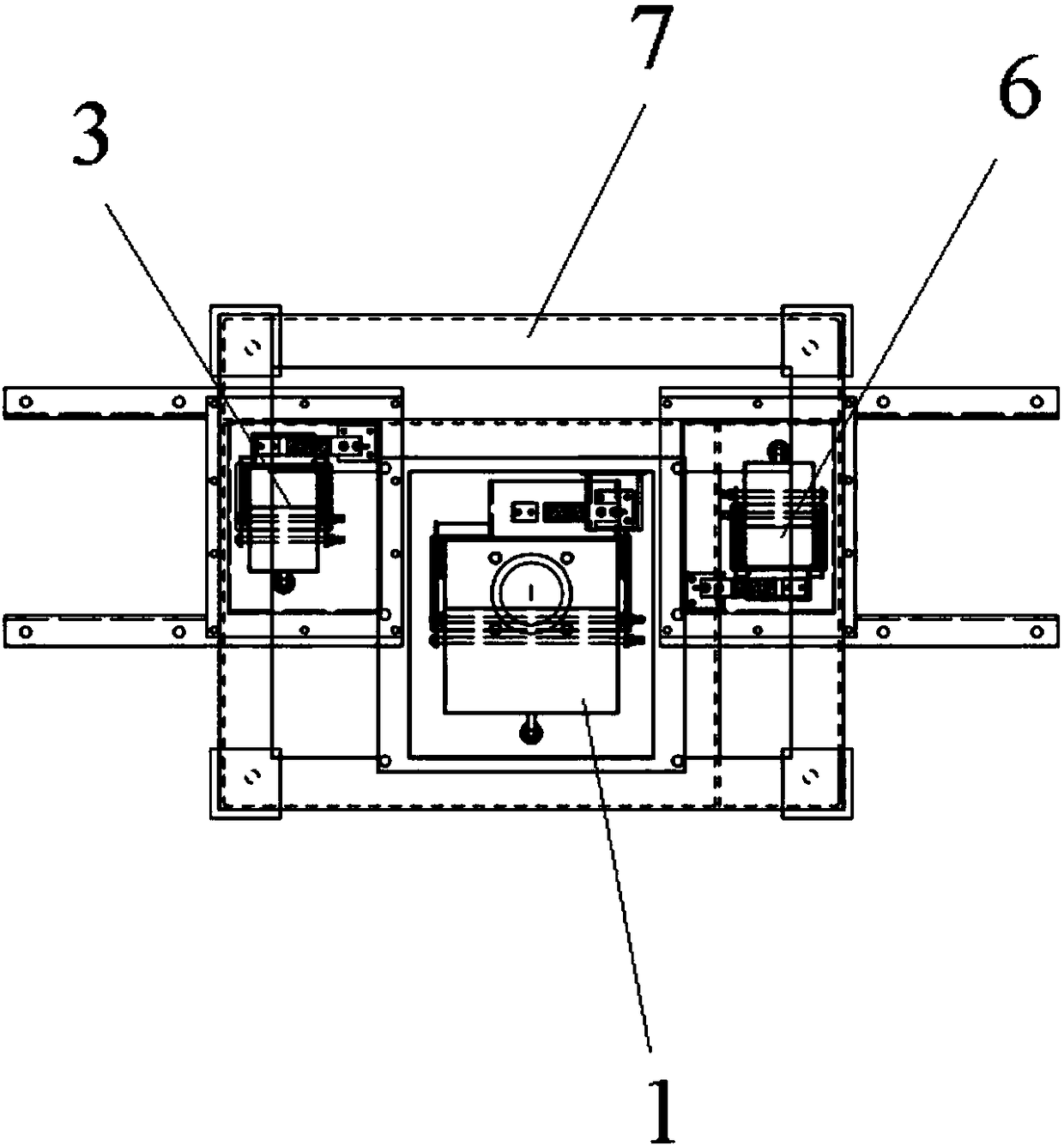

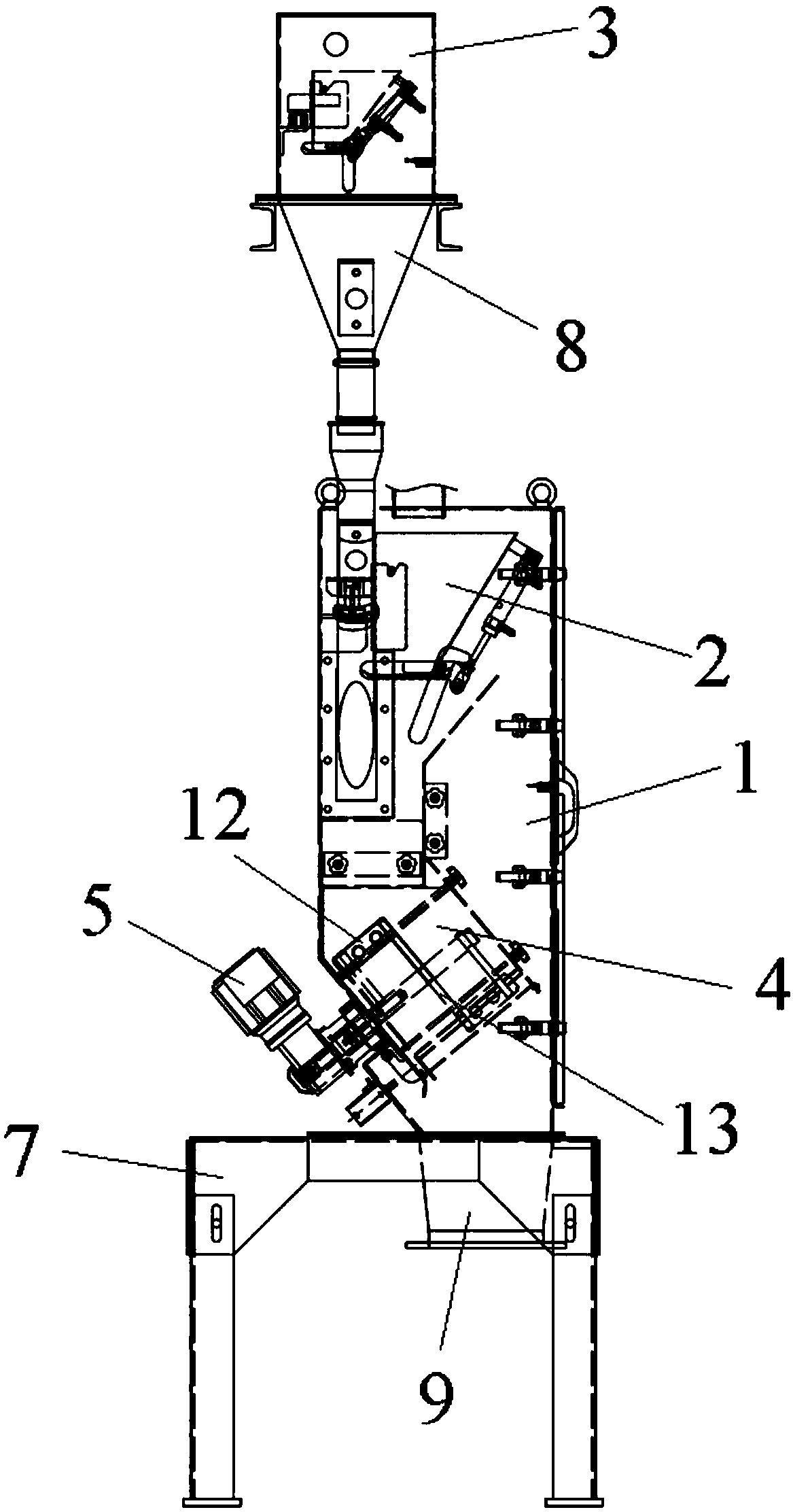

Mixing and metering device

PendingCN108311002AGuaranteed safe operationOperation impactTransportation and packagingRotary stirring mixersMechanical engineering

Owner:KAWATA MASCH MFG (SHANGHAI) CO LTD

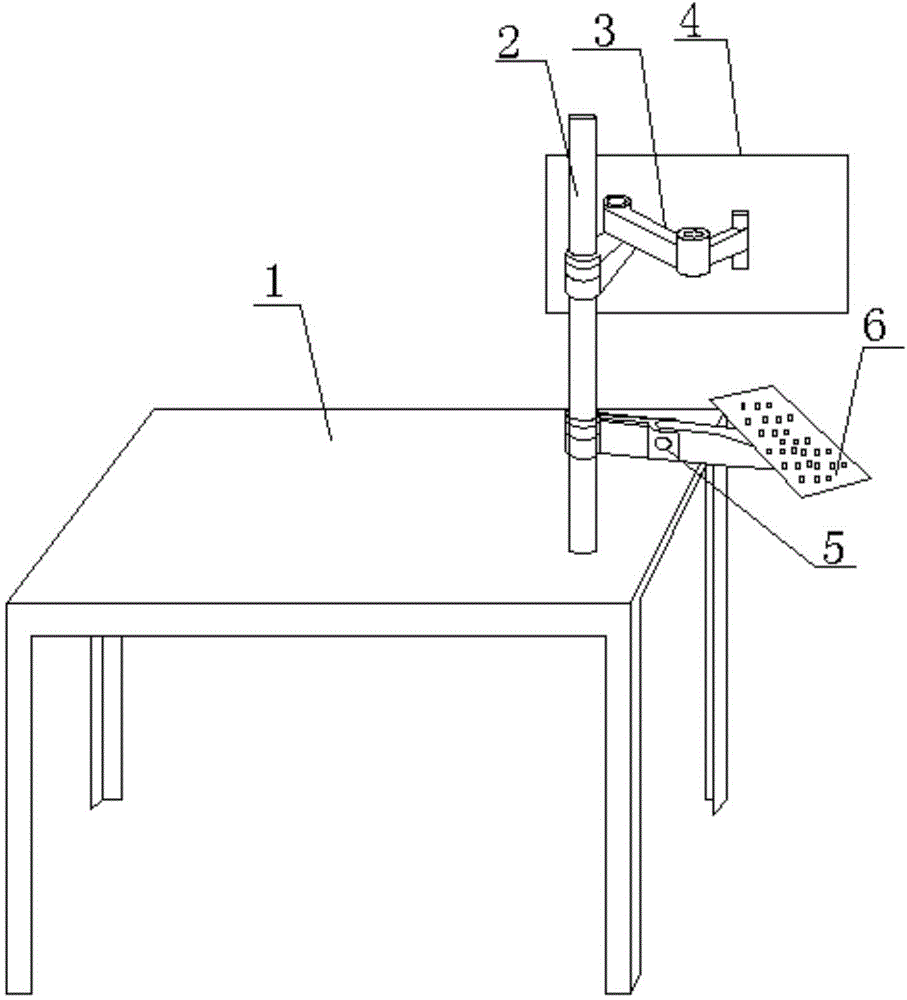

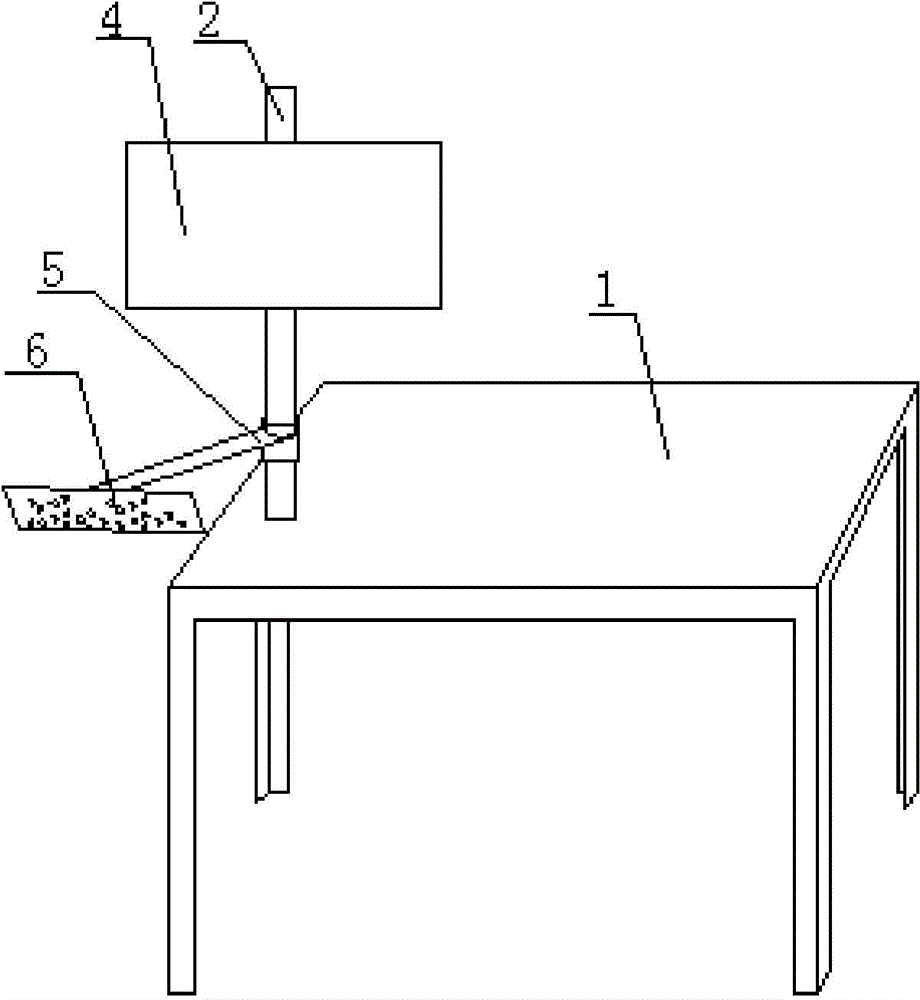

Control mechanism mounting structure of laser welding device

InactiveCN104551419AWon't take up spaceAvoid the impact of production efficiencyLaser beam welding apparatusEngineeringLaser

The invention discloses a control mechanism mounting structure of a laser welding device. The control mechanism mounting structure comprises a base and a control mechanism. The control mechanism mounting structure is characterized in that the base is provided with an upright column; the lower part of the upright column is connected with an input module of the control mechanism by virtue of a support rod; the upper part of the upright column is articulated with a connecting rod, and the other end of the connecting rod is articulated with the control mechanism. The control mechanism mounting structure has the obvious effects that the control mechanism is supported by the upper part of one side of an operation desk without occupying the space of the operation desk, so that influence on the production efficiency is avoided and the control mechanism mounting structure is convenient to use; by virtue of an articulation mode, the position of the control mechanism can be changed randomly.

Owner:CHONGQING TONGDA ENERGY EQUIP

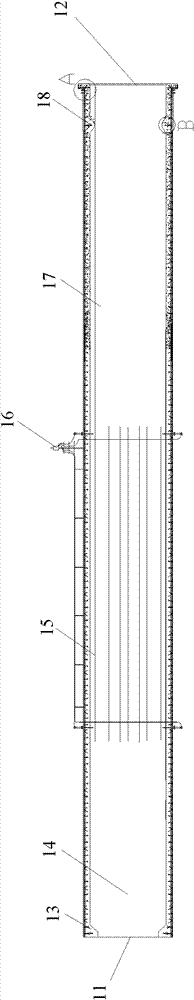

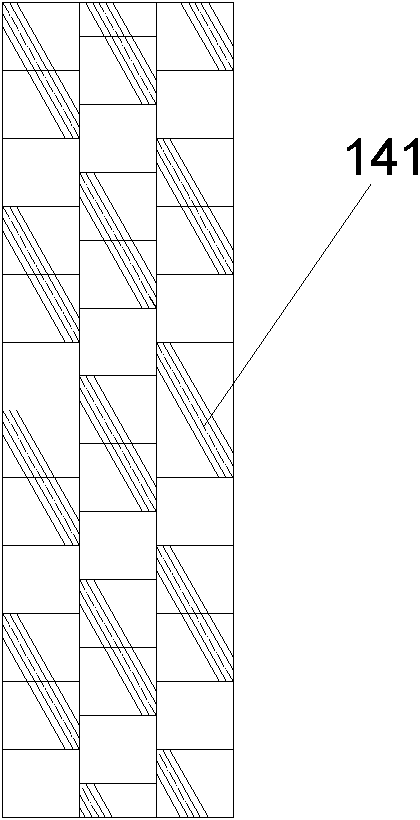

Rotary kiln and production system thereof

ActiveCN102183141BExtended service lifeReduce lossRotary drum furnacesEngineeringMechanical engineering

The invention discloses a rotary kiln and a production system thereof. The rotary kiln comprises a cylinder (1); one end of the cylinder is a feeding port (11), and the other end of the cylinder is a discharge port (12); and the cylinder (1) is sequentially provided with a material pushing section (14), a parching section (15) and a discharge section (17) from the feeding port (11) to the discharge port (12). With the rotary kiln and the production system thereof provided by the invention, filler content can be increased and material returning can be prevented, and the production efficiency can be improved.

Owner:内蒙古超牌新材料股份有限公司

Novel rolling mill balance base

PendingCN112024598AAvoid Downtime SituationsAvoid affecting productivityMetal rolling stand detailsMetal rolling arrangementsMachineRolling mill

The invention provides a novel rolling mill balance base. The novel rolling mill balance base comprises a supporting seat, a bearing seat and a roller; the two ends of the roller are installed on thebearing seat through rotating shafts; the bearing seat is erected on the supporting seat through a connecting component; a wear-resistant component is further arranged between the supporting seat andthe bearing seat; the end, close to the supporting seat, of the wear-resistant component, is an upward-pushing part; and the wear-resistant component is used for adjusting the distance between the supporting seat and the bearing seat. According to the novel rolling mill balance base provided by the invention, an existing lining plate installed on a bearing seat is replaced with an adjustable wear-resistant component, and when the lining plate at the side of the supporting seat is abraded, the distance between the supporting seat and the bearing seat can be adjusted by just adjusting the extension length of the wear-resistant component towards one side of the supporting seat; thus the situation that the machine stops working due to customized replacement of the lining plate is avoided; andinfluences on the production efficiency are avoided.

Owner:中重科技(天津)股份有限公司

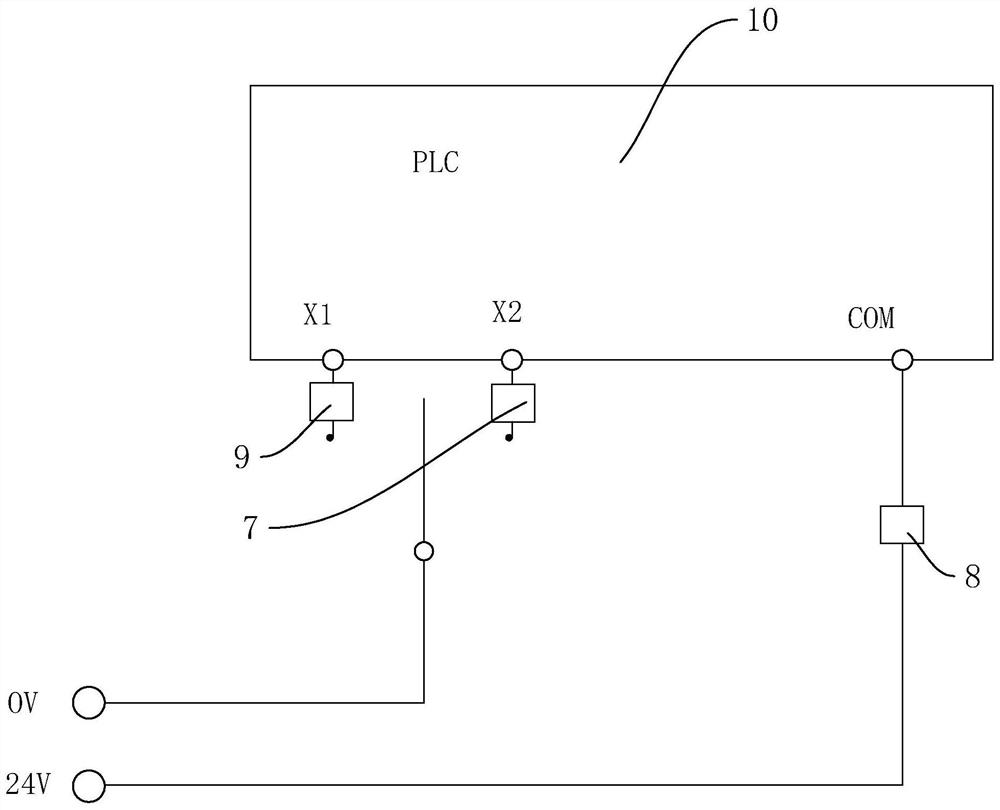

Cable conduction detection machine with compact structure

PendingCN113189516AImprove layout compactnessGuaranteed stabilityShort-circuit testingMeasurement instrument housingEngineeringKnife blades

The invention discloses a cable conduction detection machine with a compact structure, which relates to cable detection, and aims to solve the problem that a cable processing production line in the prior art lacks equipment for detecting a cable before an end is installed. Thecable conduction detection machine with a compact structure is technically characterized by comprising a mounting base, a vertical frame, an upper sliding base and a lower sliding base, wherein the upper sliding base and the lower sliding base are provided with a multi-stage contact assembly in a matched mode, the multi-stage contact assembly comprises an upper cutter set mounting base and a lower cutter set mounting base, and the upper cutter set mounting base and the lower cutter set mounting base are provided with inner core contact blades, inner insulating layer blades and shielding wire pressing heads, and the inner core contact blade, the inner insulating layer blade and the shielding wire pressure head are connected with a PLC. According to the cable conduction detection machine with the compact structure, the cable before the mounting end is mounted is detected, so that the influence on the production efficiency and the waste of raw materials caused by mounting the end at the end part of the cable which is not qualified originally are avoided.

Owner:JIAXING JUNQUAN AUTOMATION

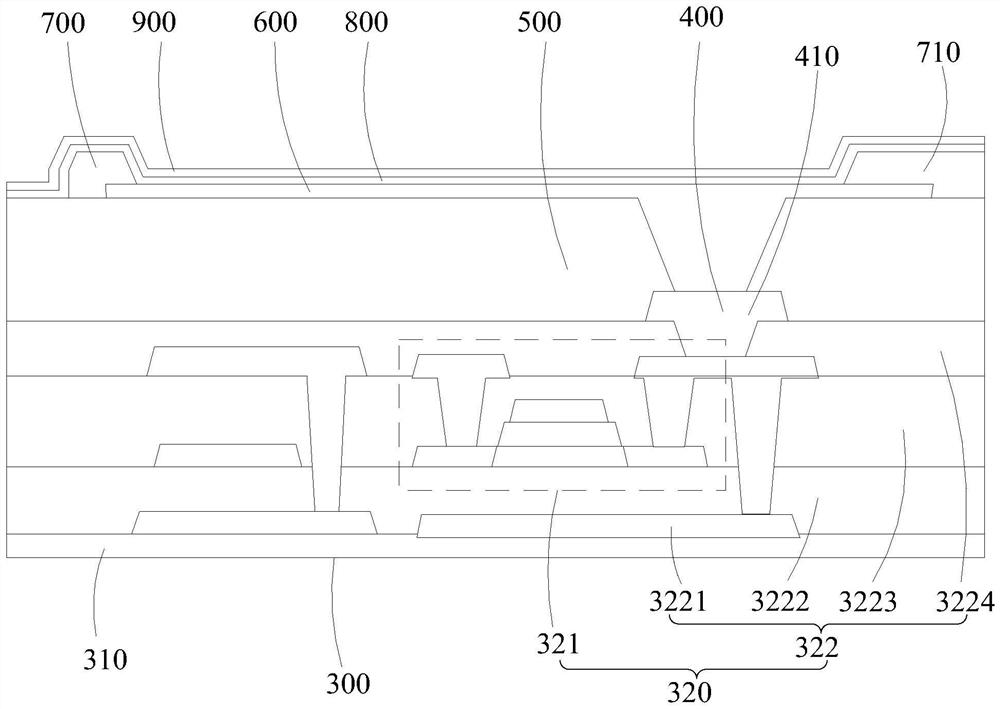

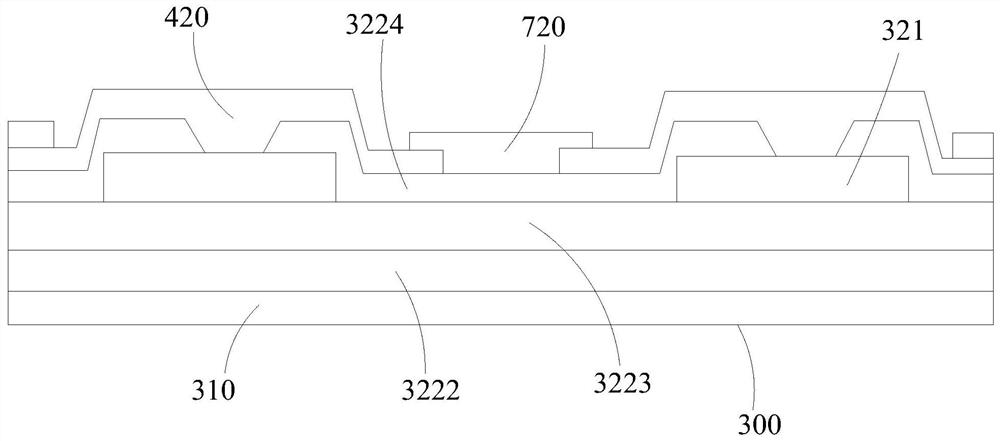

Display panel and manufacturing method thereof

PendingCN114335115APrevent looseningImprove reliabilitySolid-state devicesSemiconductor devicesEngineeringMechanical engineering

The invention provides a display panel and a manufacturing method thereof.The display panel is provided with a display area and a binding area, the display panel comprises a substrate, a circuit layer, a flat layer, an anode, a pixel definition layer, a light-emitting layer and a cathode, the substrate comprises a second insulating layer, the circuit layer is arranged on the second insulating layer, and the flat layer is arranged on the second insulating layer; the circuit layer comprises a circuit pattern arranged in the display area and a plurality of connecting wires, the connecting wires extend to the binding area from the circuit pattern, the pixel definition layer comprises a plurality of pixel retaining walls arranged on the flat layer and a plurality of bonding retaining walls arranged in the binding area, one part of each bonding retaining wall is pressed on the edge of the corresponding connecting wire, and the other part of each bonding retaining wall is pressed on the edge of the corresponding connecting wire. And the other part is pressed on the second insulating layer. The bonding retaining wall is arranged on the pixel definition layer, so that the reliability of the circuit layer in the binding area is improved, and the problem that the circuit layer in the binding area falls off is greatly solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Audio socket assembly and inspection all-in-one machine

Owner:广东正宝科技有限公司

Photo-thermal power generation system comprising diagrid industrial structure

PendingCN113931814AAvoid the impact of production efficiencyLow costFrom solar energySteam engine plantsMolten saltAir cooling system

The invention discloses a photo-thermal power generation system comprising a diagrid industrial structure. The system comprises a photo-thermal tower, a steam generator, a steam turbine, a hot fused salt tank, a cold fused salt tank, a connecting pipeline and the like. A fused salt heat absorber is supported at the top of the photo-thermal tower, is connected with cold and hot fused salt pipelines in a structure and is connected with the cold fused salt tank, the hot fused salt tank and the steam generator outside the structure, power generation is conducted through acting of the steam turbine, and the photo-thermal tower is provided with an air inlet and outlet layer which is connected with a surface radiator inside the structure, a heat return system outside the structure, a circulating water pump and the like to form a surface type indirect air cooling system. In conclusion, a high-efficiency photo-thermal power generation system is formed, the system has photo-thermal power generation and heat dissipation and indirect cooling functions, the problems that a traditional direct cooling system is large in power consumption, and an indirect cooling system is large in occupied area, long in construction period, high in initial investment and the like are solved, environmental protection performance and corrosion resistance of a project are improved, and anti-wind and anti-seismic safety performance is excellent.

Owner:TONGJI UNIV

An Intelligent Plasma Cutting Machine

ActiveCN107138835BGuaranteed normal slidingReduce labor intensityPlasma welding apparatusEngineeringDrive motor

The invention relates to an intelligent plasma cutting machine. The intelligent plasma cutting machine comprises a base, a cutting table, a cutting bridge and a cutting head; the cutting bridge further comprises a clamping mechanism; the base further comprises a sealing mechanism; the clamping mechanism comprises a driving motor, a driving plate, a fixing plate and a clamping assembly; the clamping assembly comprises a plurality of clamping units; the clamping units comprise driving blocks, connecting blocks and clamping blocks; and the sealing mechanism comprises a sealing cover, a chain belt and pulling heads. According to the intelligent plasma cutting machine, the clamping mechanism is arranged on the cutting bridge, when the cutting machine works normally, the clamping mechanism can clamp and fix the cutting head, when the cutting head needs to be replaced and maintained, the cutting head can be taken down from the clamping mechanism, disassembly is not needed, and therefore time and labor can be saved, the labor intensity can be relieved, and the influence on the production efficiency can also be avoided; and in addition, a sliding rail is sealed and protected through the sealing mechanism so that the phenomenon that the sliding rail is corroded due to long-term exposure to air can be avoided, and therefore normal sliding of the cutting bridge can be guaranteed.

Owner:青岛鼎盛源钢结构有限公司

Cigarette packaging unit

PendingCN114506521AGuaranteed uptimeReduce impactPackaging automatic controlIndividual articlesControl engineeringCarton

The invention discloses a cigarette packaging unit, relates to the field of tobacco machinery, and is used for realizing the matching of the cigarette packet conveying speed of an out-box transparent paper packaging machine and the action of pushing cigarette packets into a carton packaging machine by a cigarette packet pushing device. The packaging system comprises an out-box transparent paper packaging machine, a cigarette packet pushing device and a carton packaging machine. The cigarette packet propelling device of the out-box transparent paper packaging machine comprises a first controller, a servo motor and a push rod. The first controller is in communication connection with the servo motor; the servo motor is in driving connection with the push rod to drive the push rod to stretch. A second controller of the carton packaging machine is in communication connection with a main control motor, and the main control motor is driven by a carton conveying mechanism. The push rod is located at an inlet of the carton conveying mechanism so as to push cigarette packets conveyed by the outside-carton transparent paper packaging machine into the carton conveying mechanism. The conveying direction of the carton conveying mechanism is a second direction; the first controller is in communication connection with the second controller so that the speed of the push rod can be matched with the conveying speed of the carton conveying mechanism.

Owner:LONGYAN CIGARETTE FACTORY

A test device for high-temperature corrosion of electrodes used in glass electric melting furnaces

ActiveCN111220532BTest service lifeAvoid the impact of production efficiencyWeather/light/corrosion resistanceCrucibleCorrosion resistant

Owner:HONGGUANG MEDICINE PACKAGING

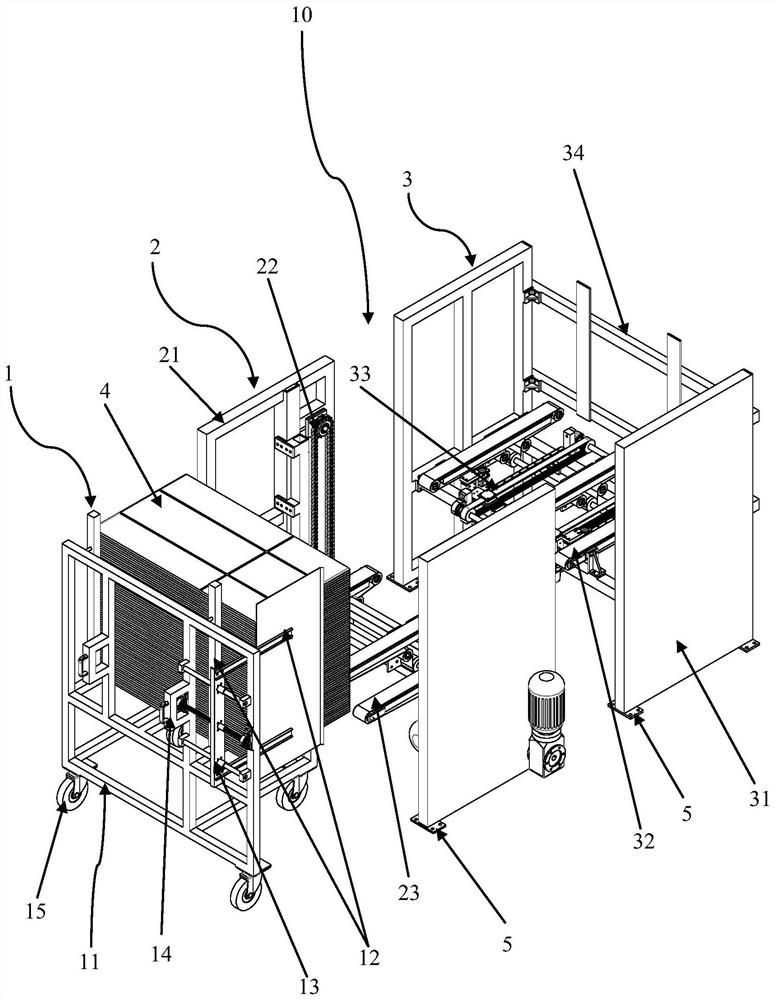

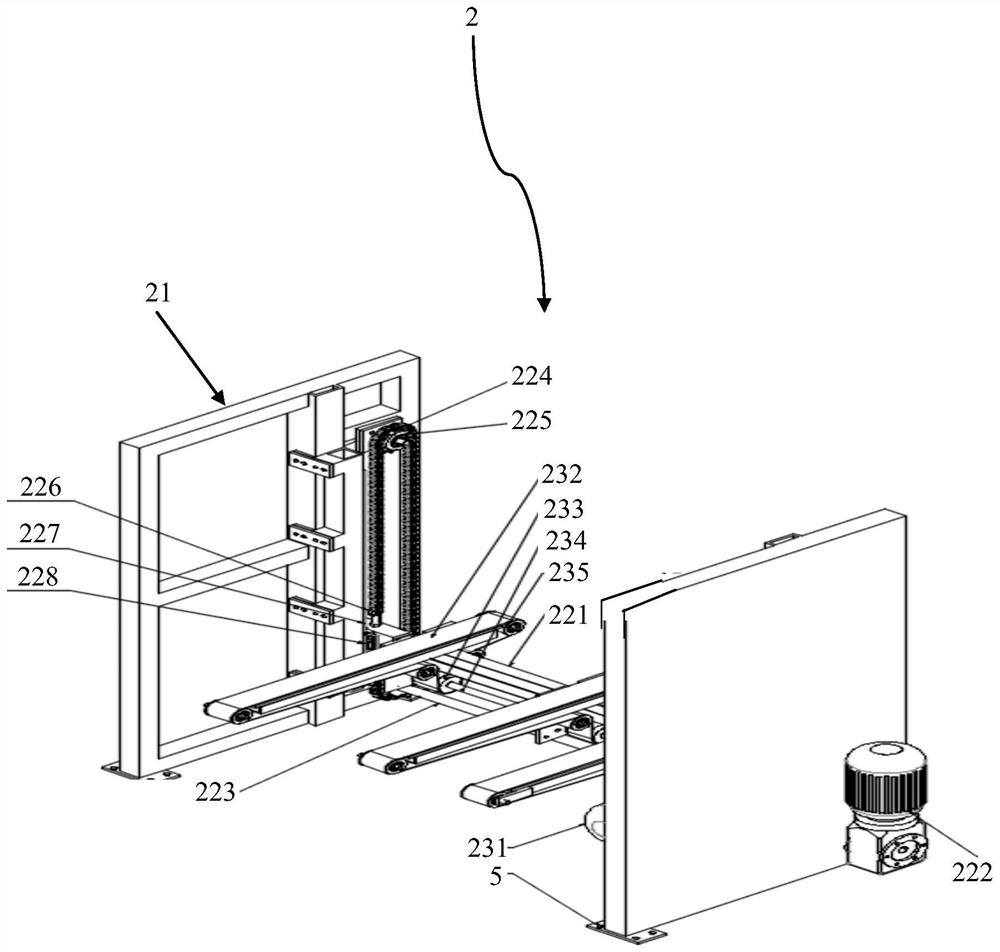

A transport mechanism for transshipment of cartons

ActiveCN112027611BAvoid the impact of production efficiencySolve the problem of material shortage shutdownConveyor partsCartonMachine

The invention provides a conveying mechanism for transferring cartons, which includes a tooling car, a lift and a carton unpacking machine. Wherein, the elevator includes an elevator main body, a lifting device and a first conveying device arranged on the elevator main body. The case unpacking machine includes a frame and a second conveying device arranged on the frame, a feeding mechanism and a case unpacking mechanism. The tooling vehicle transports the carton to a position close to the first conveying device, and the first conveying device can be in contact with the bottom of the carton. The lifting device can lift the first conveying device to the same height as the second conveying device. The first conveying device conveys the cartons to the second conveying device, the second conveying device conveys the cartons to a preset position, and the feeding mechanism pushes the cartons to the unpacking mechanism one by one. The transmission mechanism provided by the invention solves the problem of transferring the cartons to the unpacking machine by manpower in the past, reduces labor intensity, improves production efficiency, and can effectively prevent the cartons from being reversed.

Owner:GREE ELECTRIC APPLIANCES ZHENGZHOU +1

A high-efficiency paper tube slitting machine with adjustable cutting length

ActiveCN107097268BChange cutting lengthIncrease productivityMetal working apparatusPulp and paper industryUltimate tensile strength

The invention relates to an efficient paper tube cutting machine capable of adjusting cutting length. The efficient paper tube cutting machine comprises a machine base, a rotating shaft, a rotating driving device, a cutting driving device and a cutting device, wherein the cutting driving device comprises a first motor, a screw rod, a fixed block, sliding rods and sliding blocks; and the cutting device comprises a supporting mechanism, a cutting mechanism and a driving mechanism. According to the efficient paper tube cutting machine capable of adjusting cutting length, a plurality of blade groups with different blade intervals are arranged on one side of the rotating shaft, when a certain blade group requires to be utilized, the driving mechanism drives the blade group to rotate to the position corresponding to the rotating shaft, the cutting driving device drives blades to move, and the blades are in contact with paper tubes and cut the paper tubes; the multiple blades are arranged, so that production efficiency is high; and besides, cutting length is adjusted through switching of the different blade groups, application range is larger, the blades do not need to be changed manually, time and effort are saved, labor intensity is reduced, and production efficiency is prevented from being affected.

Owner:TONGXIANG HENGTAI PAPER TUBE

A paper cutting tube machine with automatic loading and unloading

ActiveCN106827018BEliminate potential safety hazardsReduce labor intensityMetal working apparatusDrive wheelElectric machinery

Owner:TONGXIANG HENGTAI PAPER TUBE

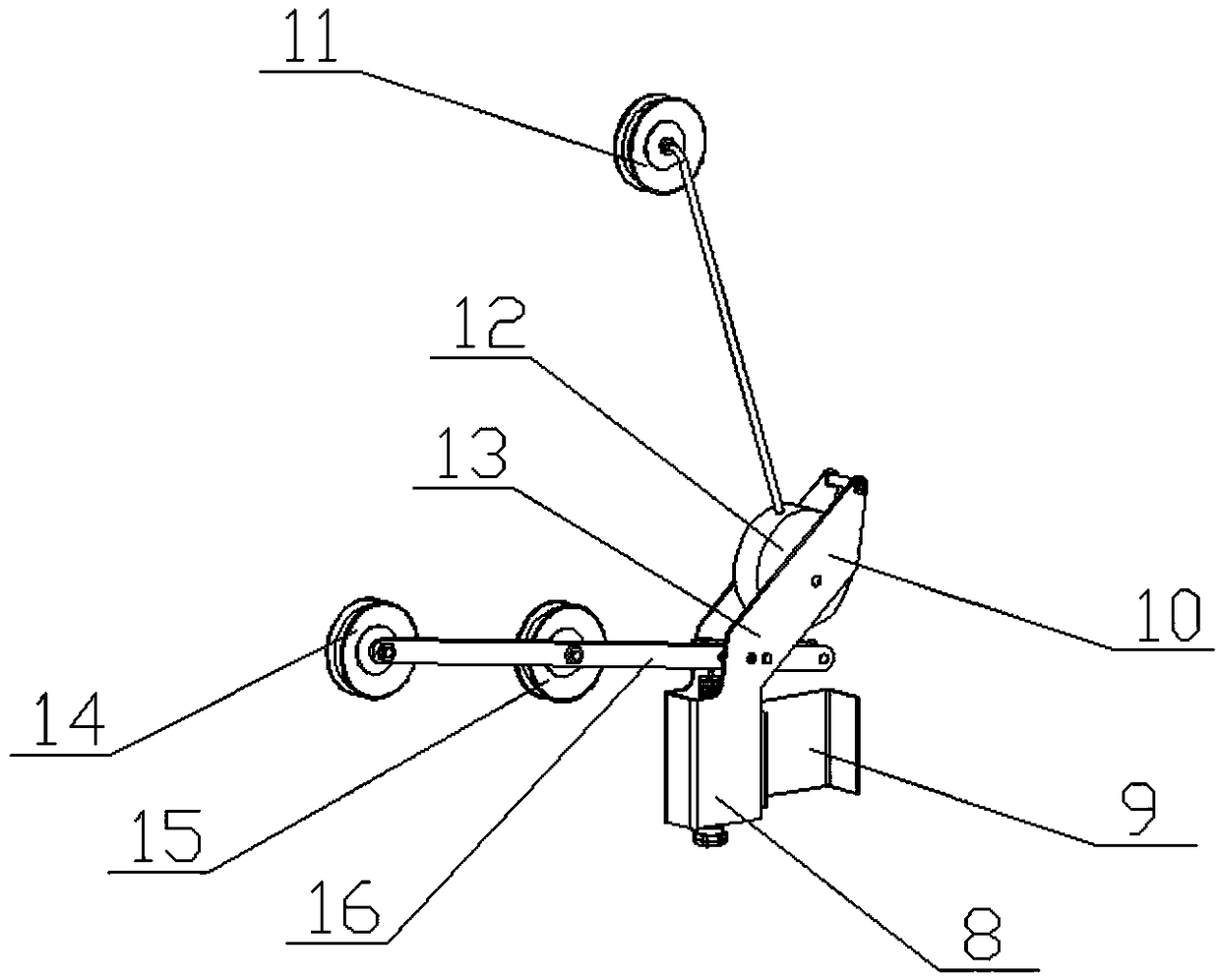

A device and method for merging cable core wires

ActiveCN105845284BImprove transmission stabilityAvoid breakageCable/conductor manufactureConductor CoilMechanical engineering

The invention discloses an apparatus and a method for combining cable core wires, belongs to the field of cable production field, and solves the problems of inconsistent loosening degree of core wire winding or even wire breaking due to external tension changes easily caused when the existing core wires are combined to a core wire reel. The apparatus comprises a wire-combining unit, wherein the wire-combining unit comprises a balance adjustment unit, a balance connecting rod and a tensioning unit; the balance adjustment unit comprises an adjusting box body, an upper pressing wheel and a pressing rod; the tensioning unit comprises a tensioning wheel; the tensioning wheel is provided with a tensioning belt; one end of the tensioning belt is fixed on the base while the other end of the tensioning belt is fixedly connected with the balance connecting rod; the upper pressing wheel is an eccentric wheel, and is arranged at the upper end of the box body through a pin shaft; the pressing rod is arranged at the middle end of the adjusting box body through the pin shaft; the tail end of the pressing rod is in contact with the upper pressing wheel; and the balance connecting rod is hinged with the tail end of the pressing rod. According to the apparus, the magnitude of the tension in the transmission process of the core wires can be automatically balanced, so that the consistent loosening degree of the core wire winding can be ensured, and the phenomenon of core wire breaking is further avoided.

Owner:METALLURGICA BRESCIANA MAANSHAN SPECIAL CABLES

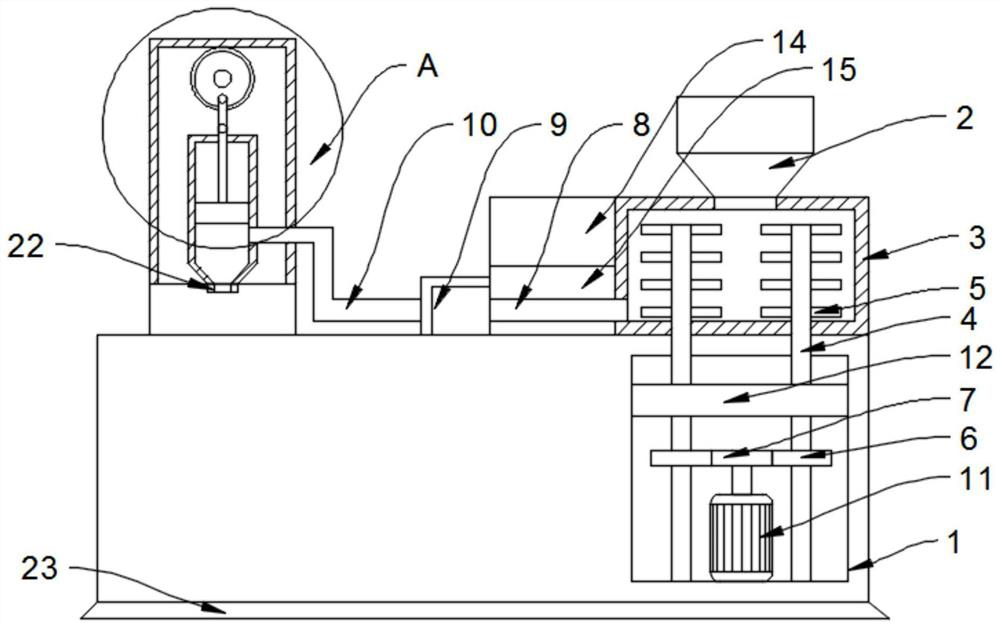

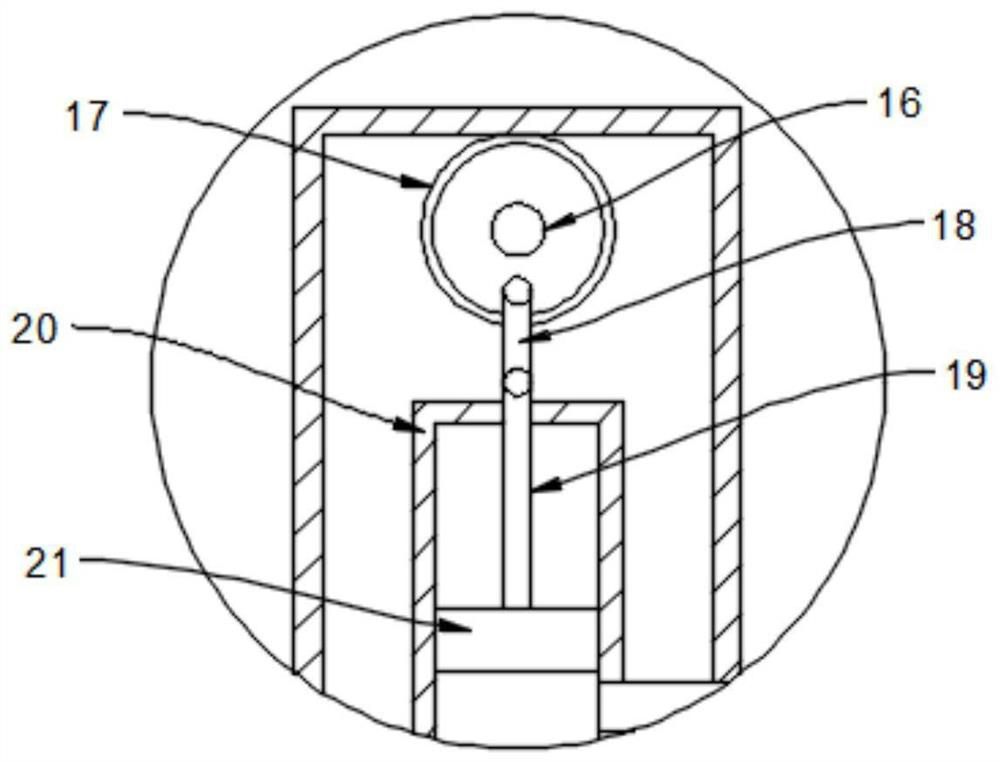

A can sealing machine with automatic capping and feeding

ActiveCN106976831BReduce labor intensityAvoid the impact of production efficiencyCapsClosure using capsEngineeringTransfer mechanism

The invention relates to a ring-pull can sealing machine capable of adding a cover and conducting feeding automatically. The ring-pull can sealing machine comprises a base, a tray, a pressing head, hobs and a driving chamber. The base further comprises a transferring mechanism and a feeding mechanism. The driving chamber further comprises a cover adding mechanism. The transferring mechanism comprises a first motor, an active wheel, a slave wheel, a belt and a can body. The feeding mechanism comprises a lifting assembly, a rotating assembly and a clamping assembly. The cover adding mechanism comprises cover storage pipes, a can cover, a supporting assembly and a cover adding assembly. The supporting assembly comprises a second air cylinder and a supporting plate. The cover adding assembly comprises a fourth motor, a lead screw, a sliding rod, a sliding block, a connecting rod and a baffle plate. According to the ring-pull can sealing machine capable of adding the cover and conducting feeding automatically, the can body is transferred below the cover adding mechanism through the transferring mechanism; the cover adding mechanism adds the cover on the can body; and then the feeding mechanism places the can body with the can cover on the tray. Compared with manual operation, the mode saves time and labor relatively, not only is the labor intensity of workers relieved, but also the influence on the production efficiency is avoided.

Owner:九江益鑫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com