Material crushing and recycling mechanism

A recycling mechanism and material technology, applied in the field of material crushing and recycling mechanism, can solve the problems that the crushing particle size cannot meet the requirements, cannot adapt to large-scale industrial production, and the throughput of raw materials is small, so as to avoid the impact of production efficiency and improve processing accuracy And processing efficiency, material screening and discharge efficient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

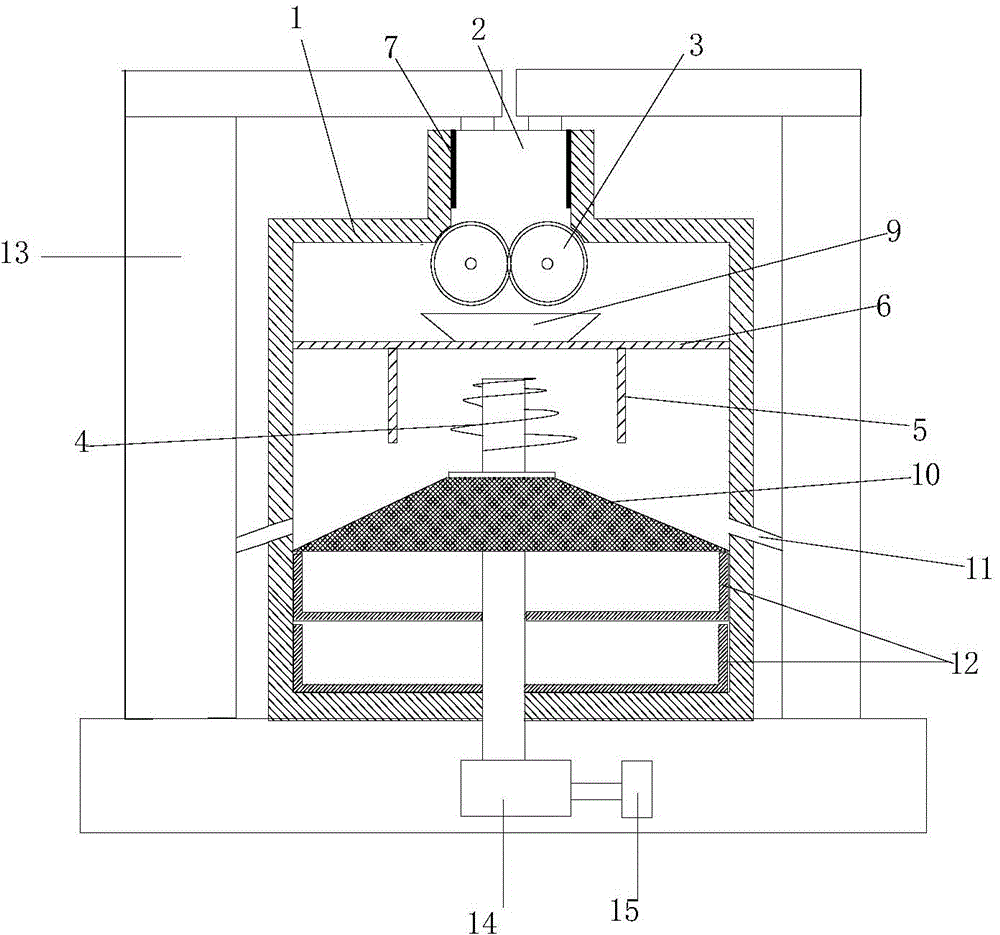

[0015] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the material crushing and recycling mechanism of the present invention includes a crushing device and a screening device driven by a power mechanism, and the crushing device includes a feeding port 2 arranged in the crushing bin 1 Two rolling rollers 3 arranged in a counter-roll manner and a spiral blade 4 connected to a rotating shaft arranged directly below the rolling roller 3 in a manner that the axis is perpendicular to the horizontal direction. The power mechanism includes a driving motor 15 and a reducer 14 And the transmission shaft, one end of the transmission shaft is in transmission cooperation with the power output shaft of the reducer 14, and the other end of the transmission shaft is in transmission cooperation with the rotation shaft. The material is first crushed by rollers and then cut and crushed by the spiral blade 4 to enhance the crushing effect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com