Grinding Chamber and Waste Food Disposal Unit

A processing device and waste food technology, which is applied in water supply devices, indoor sanitary pipeline devices, buildings, etc., can solve the problems of air cutting and ineffective crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

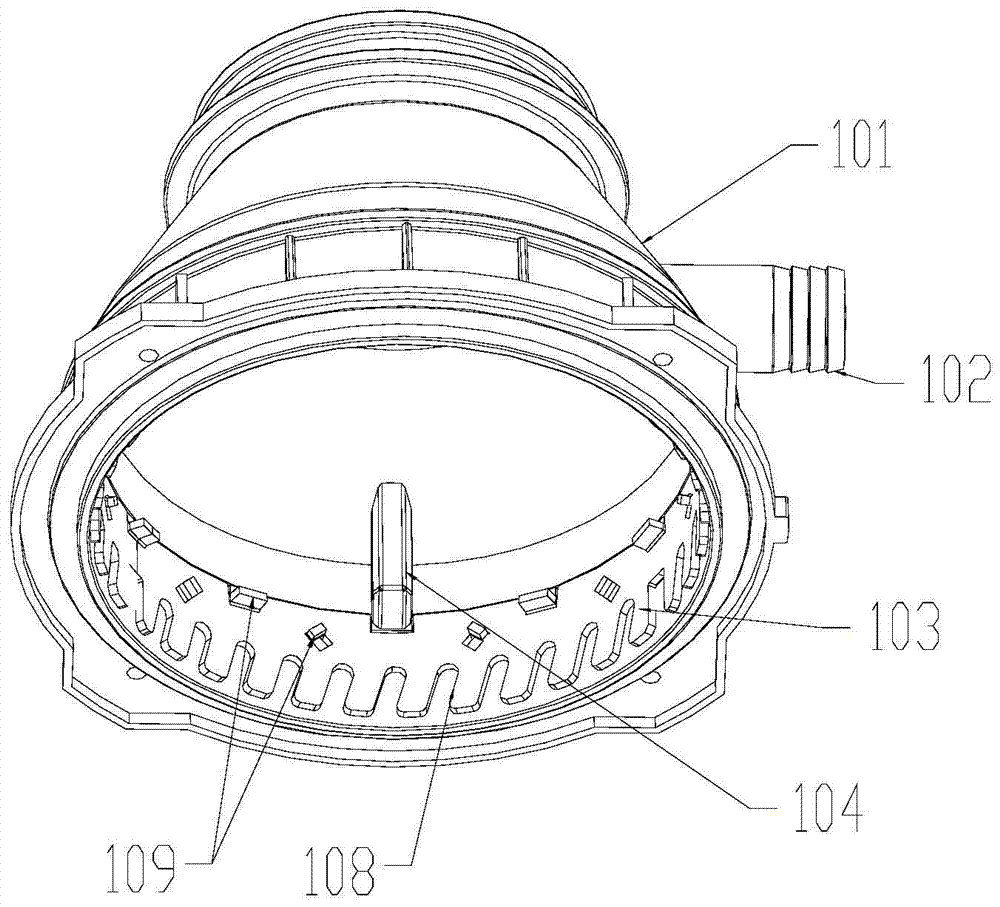

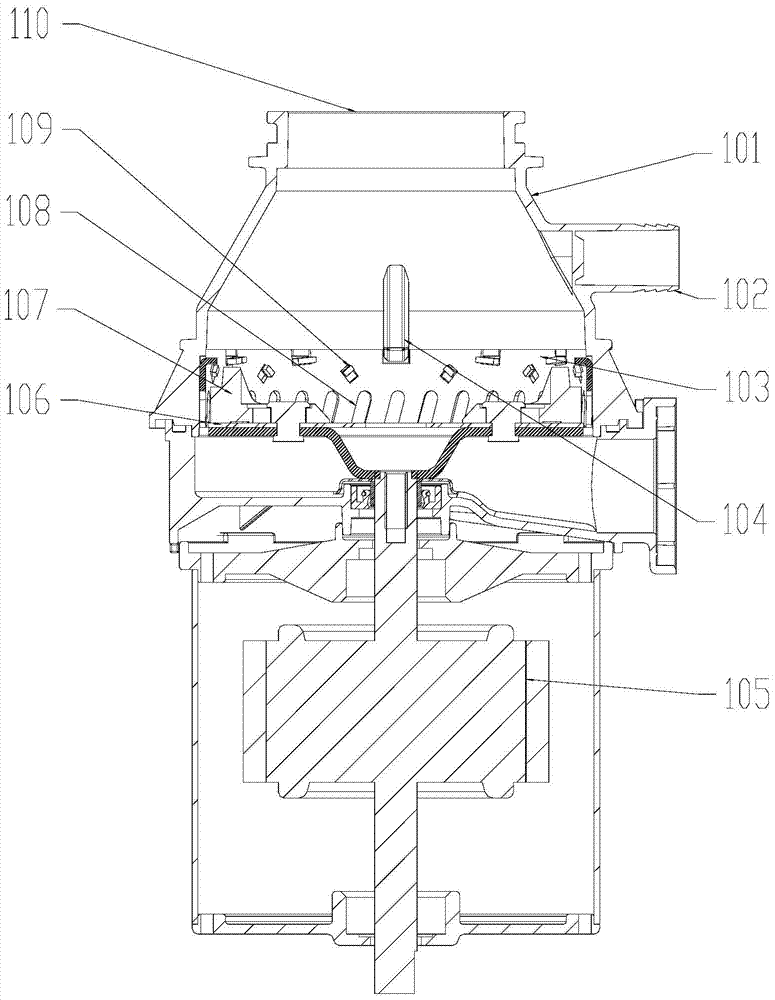

[0025] refer to figure 1 and figure 2 , The grinding chamber according to one embodiment of the present invention includes a chamber 101 having a material inlet and an inner wall of the chamber, and several protruding deceleration blocks 104 are arranged on the inner wall of the chamber. Wherein, the material inlet includes an upper opening 110 disposed on the upper part of the cavity 101 and a side opening 102 disposed on the cavity 101 .

[0026] Several protruding deceleration blocks 104 are set on the inner wall of the grinding chamber. When the food waste hits the deceleration blocks 104 during the high-speed rotation of the grinding disc, the direction and magnitude of its speed will change, and there will be a "catapult" effect. The phenomenon of rotation and air cutting will be eliminated, and food waste will be effectively cut and crushed. The invention solves the problem that when the existing waste food processor processes the non-bone food waste with high densit...

Embodiment 2

[0035] Such as figure 1 and figure 2 As shown, a waste food processing device according to an embodiment of the present invention includes a grinding chamber, a motor 105 and a grinding disc 106 . The grinding disc 106 is connected to the shaft of the motor 105, and the motor 105 drives the grinding disc 106 to rotate. A grinding block 107 is arranged on the grinding disc 106, and the grinding block 107 is used as a crushing tool. Wherein the grinding chamber is the grinding chamber in the first embodiment. Since the waste food processing device is prior art except for the above-mentioned components, the waste food processing device will not be described in detail here.

[0036] The working process of the waste food processing device of the present embodiment is as follows:

[0037] see figure 2 , food waste enters from the upper opening 110 of the grinding chamber 101 or from the side opening 102 (the dishwasher interface) of the grinding chamber 101, and falls on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com