Cigarette packaging unit

A technology for packaging units and cigarette packs, which is applied in the field of tobacco machinery and can solve the problems of cigarette pack impact and extrusion, cigarette pack accumulation, and inability to adjust in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

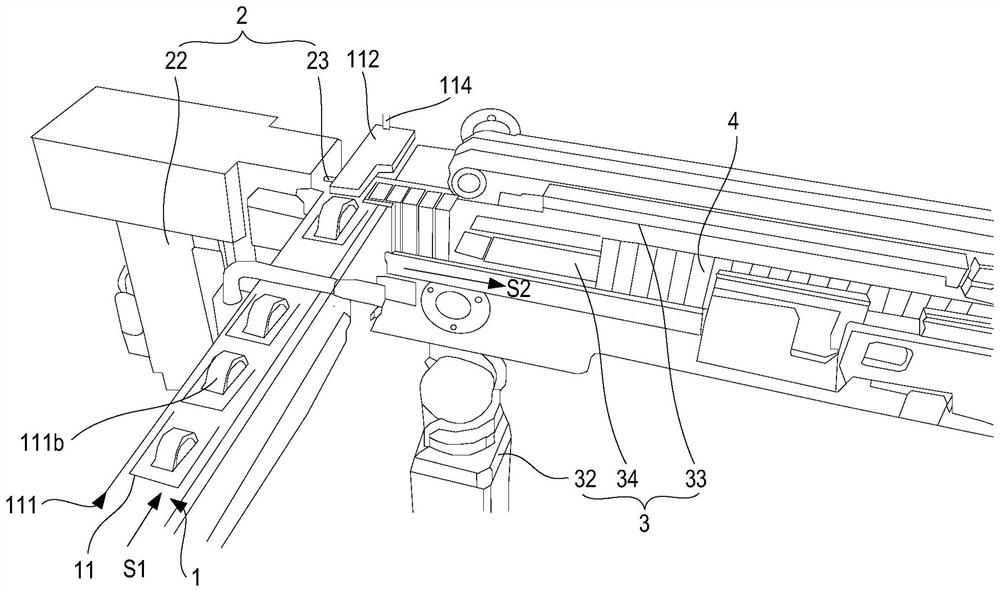

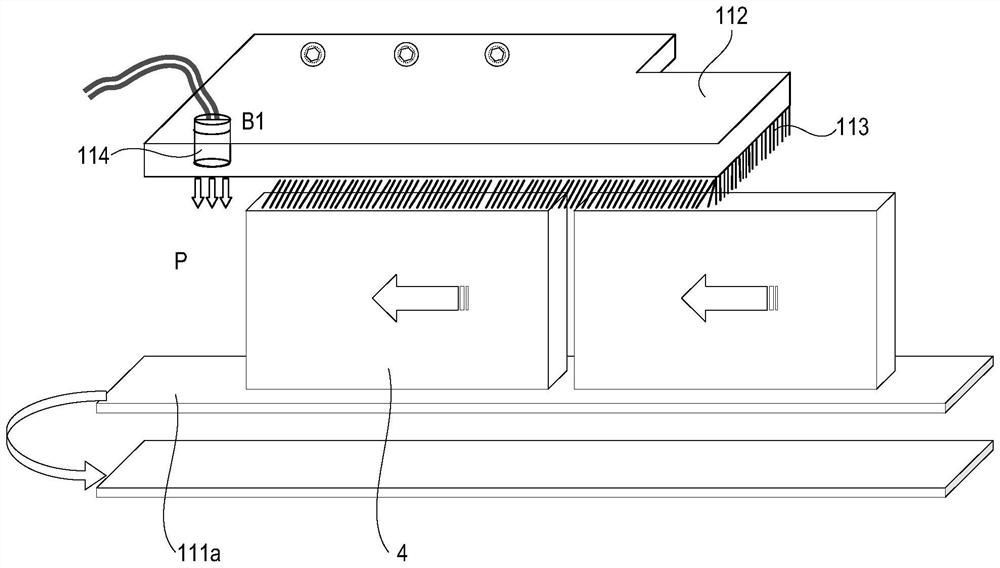

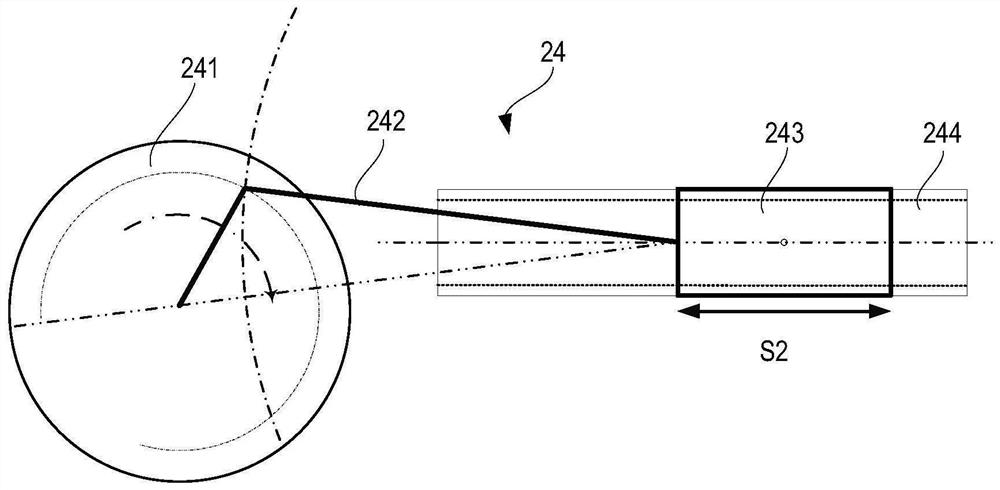

[0048] Combine below Figure 1 to Figure 6 The technical solutions provided by the present invention are described in more detail.

[0049] see figure 1 and figure 2 , The embodiment of the present invention provides a cigarette packaging unit, including a box outer transparent paper packaging machine 1 , a cigarette pack propelling device 2 and a carton packaging machine 3 .

[0050]The transparent paper packaging machine 1 outside the box is used to pack the transparent paper on the outside of the small pack of cigarettes, and then transport the small pack of cigarettes packed with the transparent paper to the downstream of itself. The cigarette pack propelling device 2 is located at this downstream position, which also corresponds to the inlet of the carton packing machine 3 . The carton packing machine 3 packs the small cigarette packs 4 into whole bars according to the set quantity. For example, every 10 packs of cigarettes constitutes a bar of cigarettes, that is, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com