Process device for electroplating air valves

A technology of process equipment and electroplating equipment, which is applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of difficult maintenance of conductive devices, difficult removal of oxide scales on conductive heads, inconvenient assembly and disassembly, etc., so as to improve the utilization rate of equipment and the intact rate of equipment , shorten the auxiliary time, reduce the effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

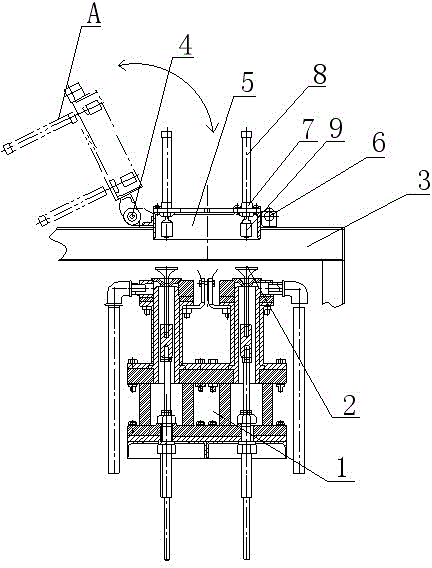

[0013] Such as figure 1 As shown, the process device for valve electroplating of the present invention comprises an electroplating device 1, two valves 2 are arranged on the electroplating device 1, and a fixed support 3 is arranged above the electroplating device 2, and the fixed support 3 is connected to the cathode movable support 5 through the flip hinge 4. Flexible connection, one side of the cathode movable support 5 is also provided with a locking pin 6 fixedly connected with the fixed support 3, a conductive clamping cylinder 7 is installed on the cathode movable support 5, and two piston rods 8 are installed on the conductive clamping cylinder 7 , the lower end of each piston rod 8 is equipped with a conductive head 9, and the position of the conductive head 9 is directly above the valve 2. During the electroplating process, the cathode movable support 5 is first turned over to the disassembly position A through the turning hinge 4, and then the valve 2 is put into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com