Intelligent plasma cutting machine based on Internet of Things

A technology of plasma cutting machine and Internet of things, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increased labor intensity, inconvenient maintenance, easy to be corroded, etc., to reduce labor intensity and avoid production efficiency effect, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

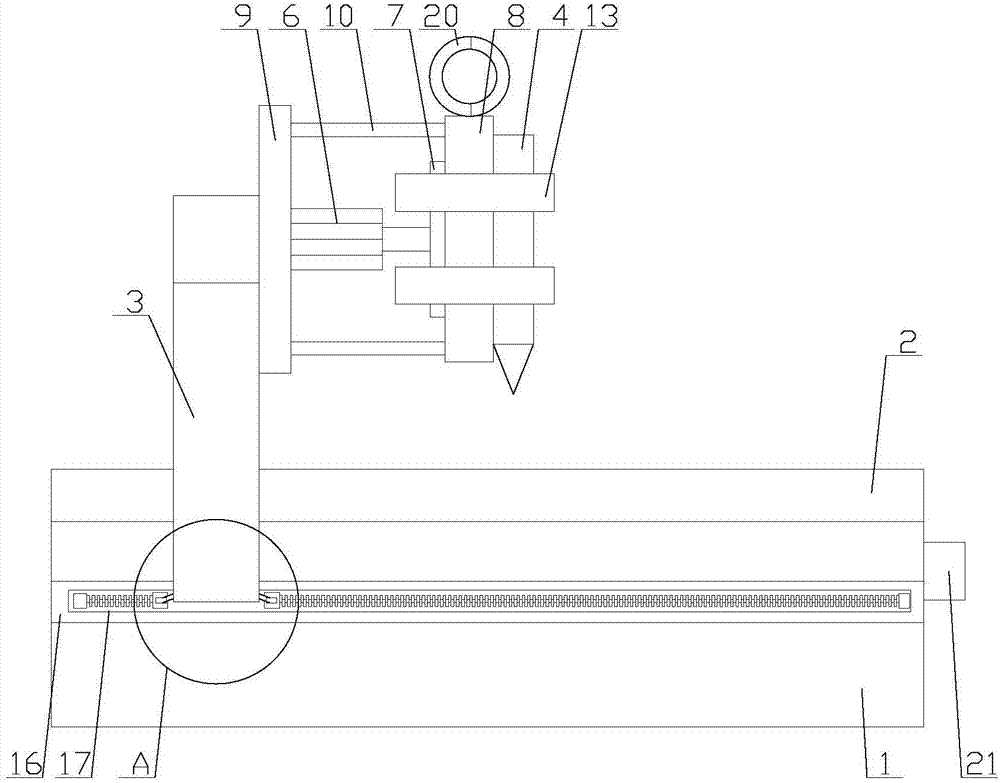

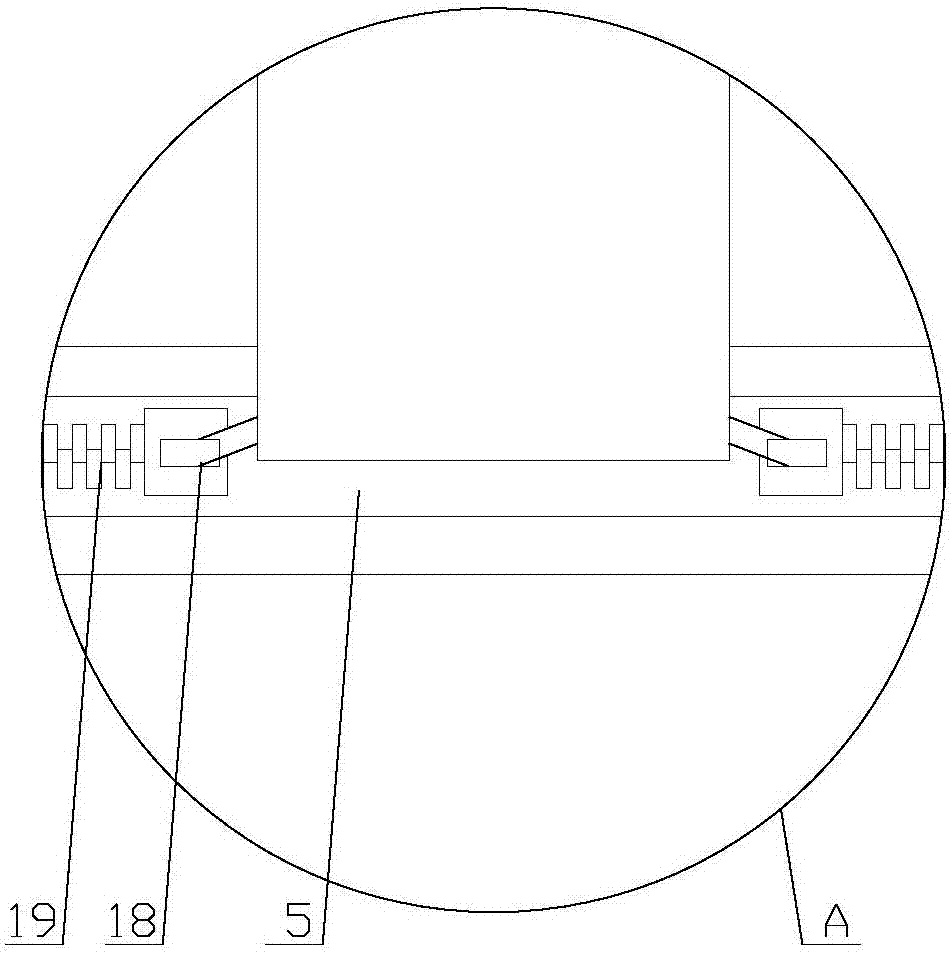

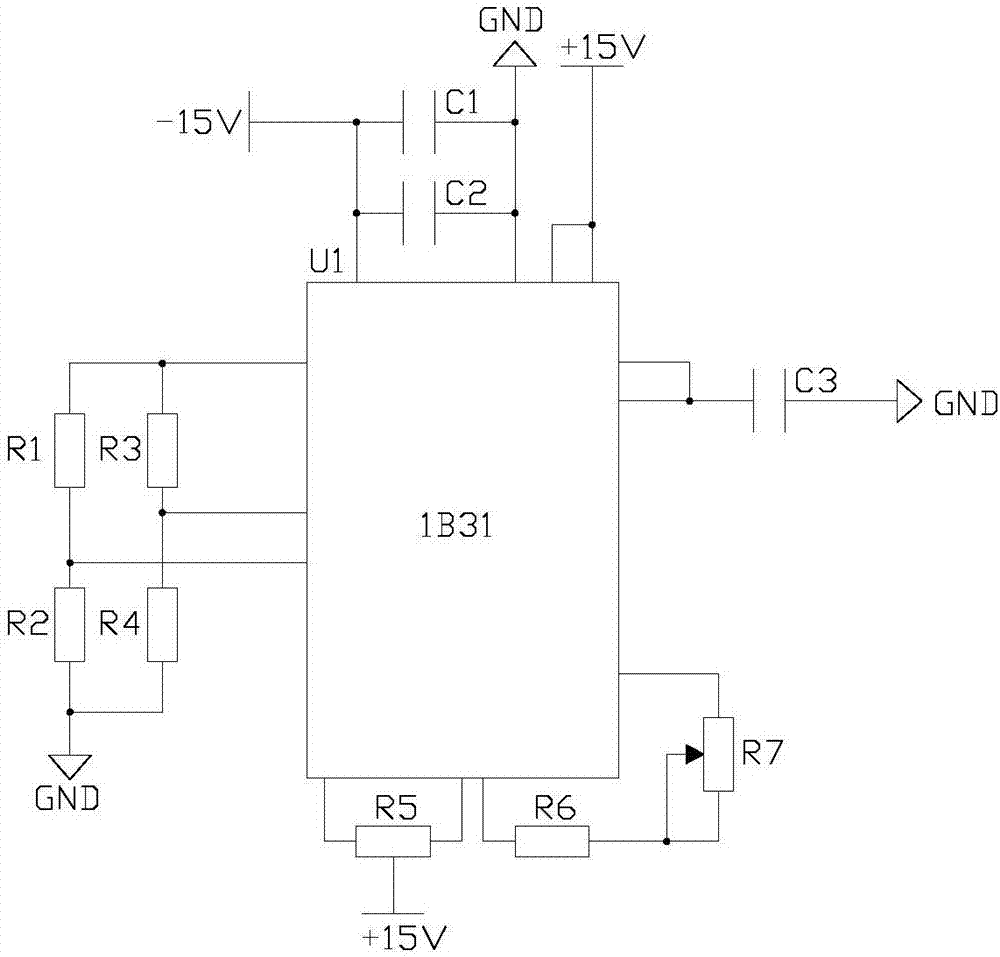

[0027] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0028] Such as Figure 1-5 As shown, an intelligent plasma cutting machine based on the Internet of Things includes a base 1, a cutting table 2, a cutting bridge 3 and a cutting head 4, and the cutting bridge 3 also includes a clamping mechanism, which is arranged at the cutting Between the bridge 3 and the cutting head 4, the base 1 also includes a sealing mechanism, the base 1 is provided with a slide rail 5, the bottom of the cutting bridge 3 is slidably connected with the slide rail 5, and the sealing mechanism is arranged on the slide rail 5. on track 5;

[0029] The clamping mechanism includes a driving motor 6, a driving plate 7, a fixed plate 8 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com