Metal-based powder metallurgy brake pad for high-speed train and preparation method thereof

A technology of powder metallurgy and high-speed trains, applied to friction linings, mechanical equipment, etc., can solve problems such as complex manufacturing process, friction performance attenuation, adhesive wear, etc., and achieve small fluctuations in friction coefficient, stable friction coefficient, and small thermal decay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

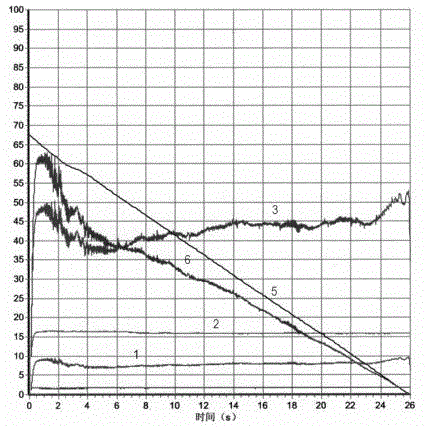

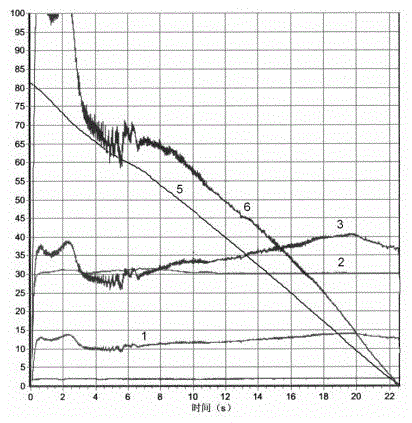

Image

Examples

Embodiment

[0037] The metal-based powder metallurgy brake pads used for high-speed trains of this embodiment are made of the following materials:

[0038] Matrix components: electrolytic copper powder, 45% by weight; iron powder, 30% by weight (iron powder includes reduced iron powder and ferroalloy powder, the ferroalloy powder used is ferromanganese powder, accounting for 10wt% of iron powder);

[0039] Lubricating components: graphite powder, 12% by weight; molybdenum disulfide, 3% by weight;

[0040] Friction components: metallic tungsten, 2% by weight; corundum, 2% by weight; silica sand, 2% by weight; boron carbide, 2% by weight;

[0041] Friction stability component: carbon fiber powder (400 mesh, 6 micron CVD coating on the surface), 2% by weight;

[0042] Bonding material: phenolic resin, the amount is 5% of the sum of the weight of each component.

[0043] The preparation method includes the following steps:

[0044] (1) Ingredients: Weigh the raw materials of each component according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com