Wet multi-disc parking brake

A parking brake and brake technology, which is applied to hydraulic brakes, brake actuators, etc., can solve the problems of cumbersome replacement and maintenance of friction plates, difficulty in entering oil between friction pairs, wear of friction plates, etc. The effect of preventing dry friction and improving braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

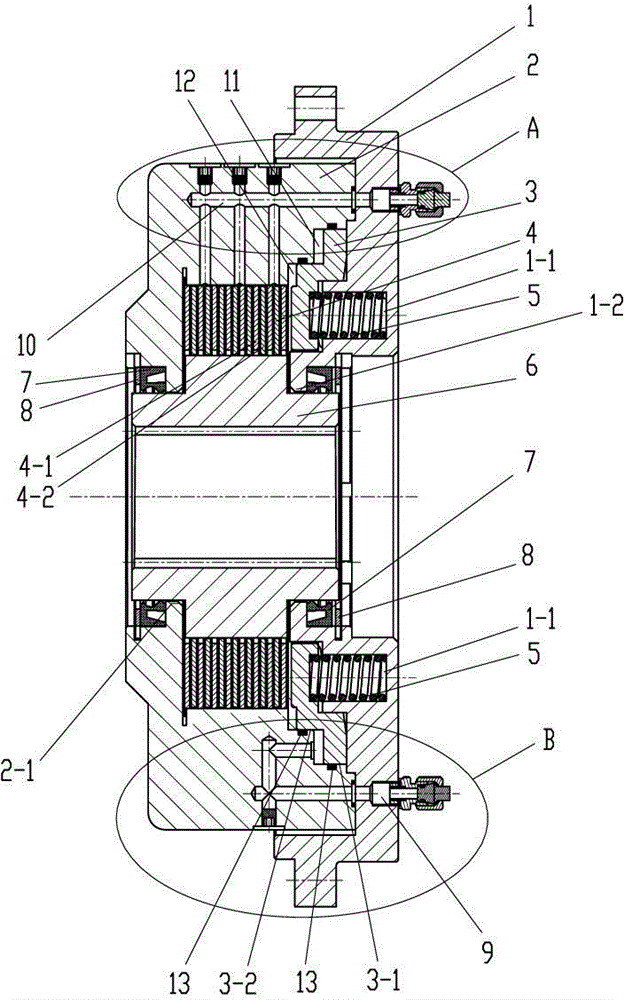

[0027] Such as figure 1 , 2 , 3, the wet multi-plate parking brake of the present invention includes a brake cover 1, a brake housing 2, a piston 3, a friction pair 4, a spring 5, a spline shaft 6 and a seal 7,

[0028] The brake cover 1 is fixedly connected with the brake housing 2 to form a brake box, and the piston cylinder surrounded by the brake cover 1 and the brake housing 2 is equipped with a piston 3 capable of moving left and right.

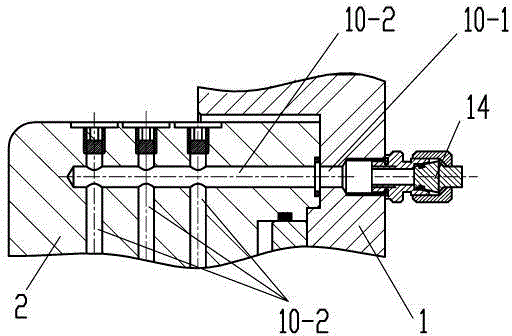

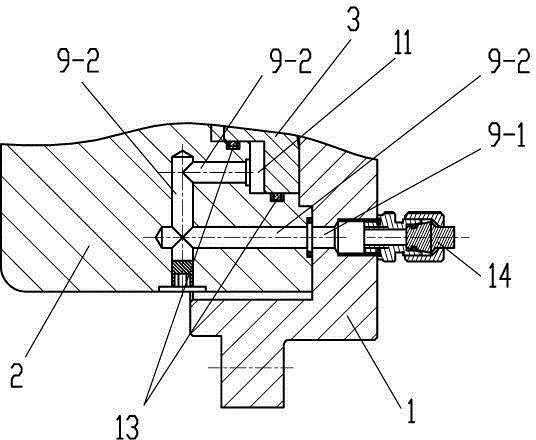

[0029] The piston cylinder includes a first cylinder hole 11 with a larger diameter and a second cylinder hole 12 with a smaller diameter, and the piston 3 has a first sliding surface 3-1 with a larger diameter and a second sliding surface with a smaller diameter 3-2, the first sliding surface 3-1 of the piston 3 is slidingly matched with the hole wall of the first cylinder hole 11, and the second sliding surface 3-2 is slidingly matched with the hole wall of the second cylinder hole 12,

[0030] There are several spring mounting hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com