Multifunctional giant frame inclined grid industrial structure

A giant frame and structure technology, applied in the field of multi-functional giant frame inclined grid industrial structures, can solve the problems of large-diameter axial fans with large noise, overall construction difficulties, and poor environmental protection performance, so as to improve environmental performance and corrosion resistance , wind and earthquake resistance, excellent safety performance, and strong energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

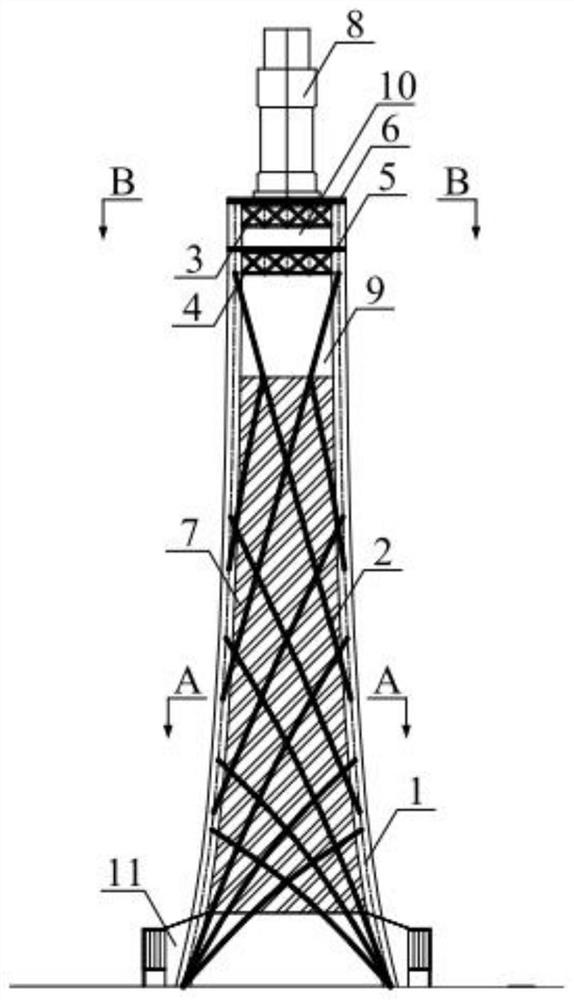

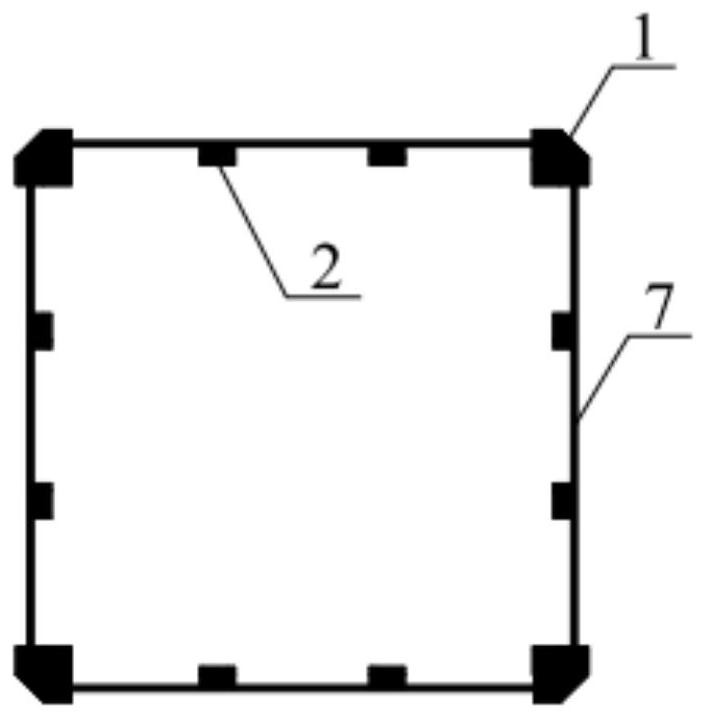

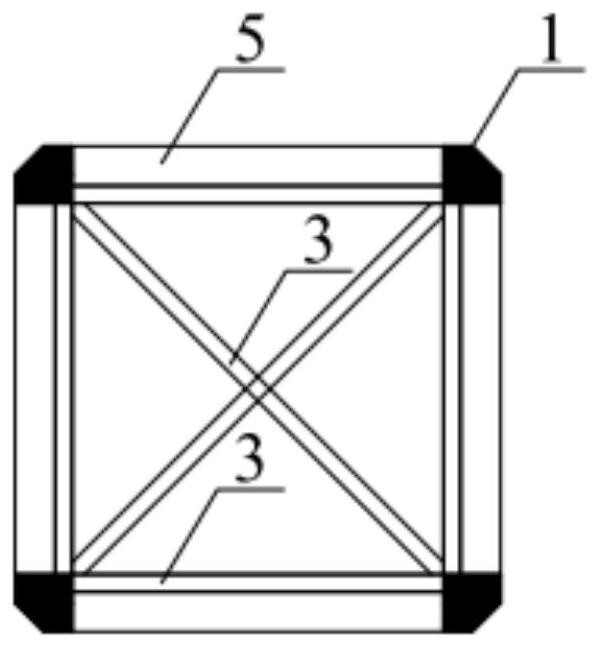

[0037] see figure 1 , figure 2 and image 3 , as an example only.

[0038] Such as Figure 1-3 As shown, a multi-functional giant frame diagonal grid industrial structure, including giant frame column 1, diagonal grid 2, upper truss beam 3, lower truss beam 4, combined bottom plate 5, combined top plate 6 and surface skin 7, And set the molten salt heat absorber 8;

[0039] The giant frame columns 1 are set at the corners of the structure. There are four in total, and they run through the whole structure. The composite cross-section of the steel pipe concrete with multiple cavities is adopted in the shape of a pentagon. Progressive distribution;

[0040]The oblique grid 2 is formed by multi-channel through diagonal braces crossing the giant frame columns 1 at the corners, which are made of steel pipe concrete or other composite material diagonal braces, and connects the giant frame columns 1 on both sides in multiple sections. Arranged from dense to sparse, a total of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com